Philips Lighting Company | www.philips.com | Philips Lighting |

200 Franklin Square Drive |

| 281 Hillmount Road |

P.O. Box 6800 |

| Markham, Ontario |

Somerset, NJ |

| Canada L6C 2S3 |

| ||

A Division of Philips Electronics North America Corporation | A Division of Philips Electronics Ltd. | |

Printed in USA 07/05 |

| |

Tungsten Halogen PAR Lamps

Electrical,Technical and Ordering Data (Subject to change without notice)

|

|

|

|

|

|

|

|

|

|

|

|

| Rated |

|

|

|

|

|

| Std. |

| Heat |

|

|

|

|

| Average | Approx. |

| Product |

| ANSI |

| Pkg. |

| Resistant | Bulb |

| Beam | Candle- | Initial | Life | Color |

| Number | Description | Code | Watts | Qty. | Volts | Description | Type | Base | Angle1 | Power2 | Lumens | (Hrs.)3 | Temp. |

| 500PAR56Q/NSP |

| 500 | 8 | 120 | Narrow Spot | Mog. End | 17 x 34 | 88,000 | 3500 | 4000 | 3000 | ||

| 500PAR56Q/MFL |

| 500 | 8 | 120 | Med. Flood | Mog. End | 20 x 48 | 47,000 | 3800 | 4000 | 3000 | ||

| 500PAR56Q/WFL |

| 500 | 8 | 120 | Wide Flood | Mog. End | 28 x 70 | 22,500 | 5000 | 4000 | 3000 | ||

| 1000PAR64Q/NSP |

| 1000 | 8 | 120 | Narrow Spot | Ext. Mog End | 16 x 28 | 200,000 | 9800 | 4000 | 3000 | ||

| 1000PAR64Q/MFL |

| 1000 | 8 | 120 | Med. Flood | Ext. Mog End | 24 x 44 | 80,000 | 12,000 | 4000 | 3000 | ||

| 1000PAR64Q/WFL |

| 1000 | 8 | 120 | Wide Flood | Ext. Mog End | 42 x 76 | 31,000 | 14,800 | 4000 | 3000 | ||

| 1000PAR64QVNSP | FFN | 1000 | 8 | 120 | Very Narrow Spot | Ext. Mog End | 12 x 6 | 400,000 | 11,000 | 800 | 3200 | ||

| 1000PAR64QNSP | FFP | 1000 | 8 | 120 | Narrow Spot | Ext. Mog End | 14 x 7 | 330,000 | 12,000 | 800 | 3200 | ||

| 1000PAR64QMFL | FFR | 1000 | 8 | 120 | Med. Flood | Ext. Mog End | 28 x 12 | 120,000 | 14,000 | 800 | 3200 | ||

| 100PAR64QWFL | FFS | 1000 | 8 | 120 | Wide Flood | Ext. Mog. End | 55 x 22 | 40,000 | 19,000 | 800 | 3200 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1)Beam Spread to 50% peak candlepower.

2)Candlepower Average in central 5˚ cone for spot to 10˚ cone for flood.

3)Rated Average Life is the length of operation (in hours) at which point an average of 50% of the lamps will still be operational and 50% will not. Note: Lamps can be operated in ANY position.

Operation & Handling

Studio and theater lamps require care to gain optimum performance with every use. Handling the glass of a quartz lamp should be avoided. It is advisable to use gloves when touching a lamp. Should the lamp be touched, careful cleaning can be done with a solvent such as alcohol. Shielding of halogen lamps is generally considered an advisable precaution.

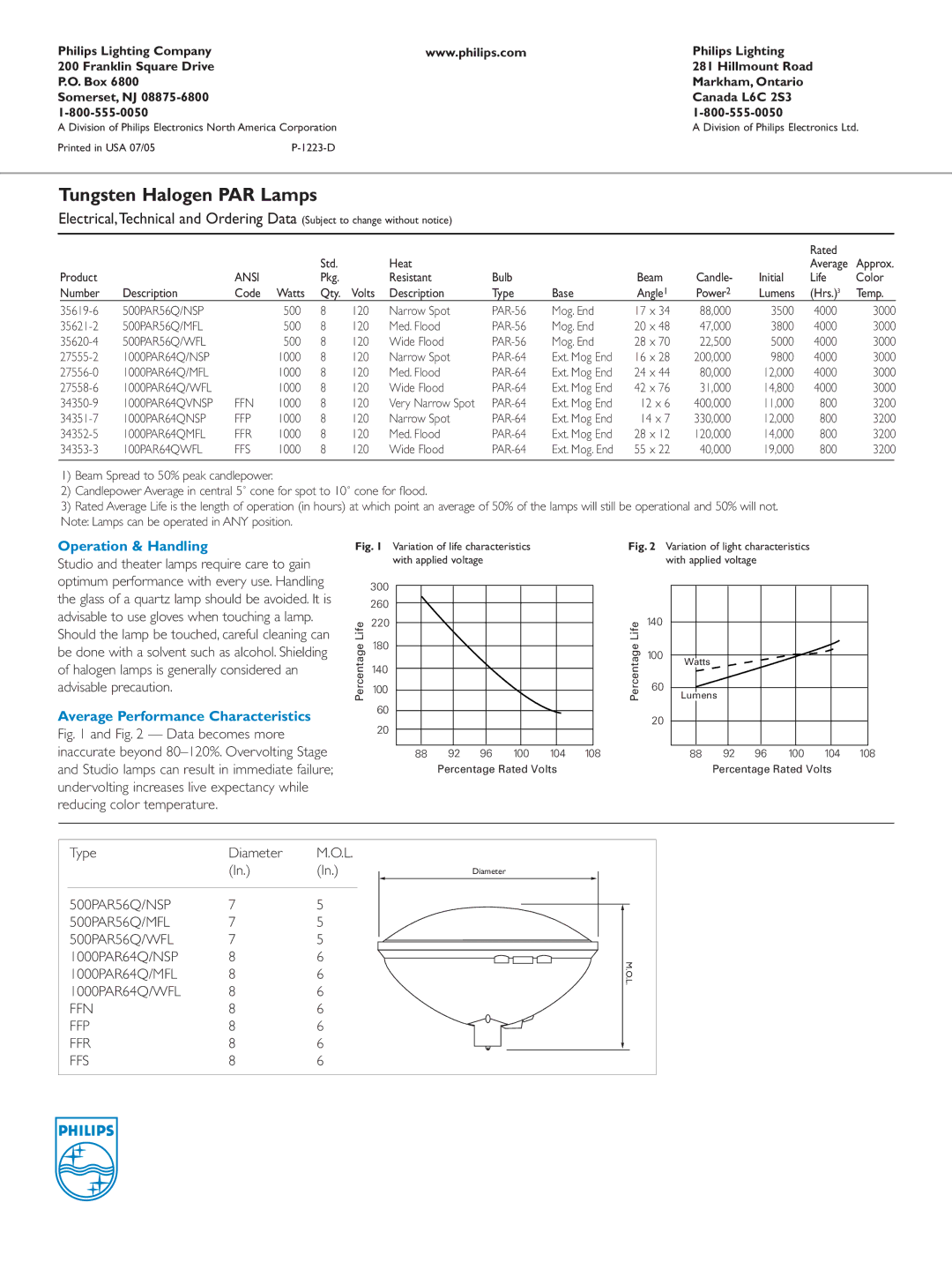

Average Performance Characteristics

Fig. 1 and Fig. 2 — Data becomes more inaccurate beyond 80–120%. Overvolting Stage and Studio lamps can result in immediate failure; undervolting increases live expectancy while reducing color temperature.

Fig. 1 Variation of life characteristics

with applied voltage

| 300 | |

| 260 | |

Life | 220 | |

180 | ||

Percentage | ||

140 | ||

| ||

| 100 |

60

20

88 92 96 100 104 108

Percentage Rated Volts

Fig. 2 Variation of light characteristics

with applied voltage

Life | 140 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Percentage | 100 | Lumens |

|

|

|

|

|

|

|

|

| |||

|

| Watts |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| 60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 88 | 92 | 96 | 100 | 104 | 108 | |||||||

|

|

|

|

| Percentage Rated Volts |

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type | Diameter | M.O.L. |

|

| (In.) | (In.) | Diameter |

500PAR56Q/NSP | 7 | 5 |

|

500PAR56Q/MFL | 7 | 5 |

|

500PAR56Q/WFL | 7 | 5 |

|

1000PAR64Q/NSP | 8 | 6 | M.O.L |

1000PAR64Q/MFL | 8 | 6 | |

1000PAR64Q/WFL | 8 | 6 | . |

| |||

FFN | 8 | 6 |

|

FFP | 8 | 6 |

|

FFR | 8 | 6 |

|

FFS | 8 | 6 |

|