L20-332 specifications

The Pitco Frialator L20-332 is an exceptional commercial deep fryer designed for high-volume frying operations. Delivers reliability, efficiency, and advanced technology tailored for busy kitchens, this unit is a top choice for restaurants, cafes, and catering services. Its robust construction and innovative designs make it ideal for frying a variety of foods, from crispy French fries to golden chicken wings.One of the standout features of the L20-332 is its high production capacity. With a generous 40 lbs. oil capacity per tank, the fryer is capable of supporting large batches, making it possible to keep up with customer demand during peak hours. The fryer is equipped with two fry tanks, providing a total oil capacity of 80 lbs., which allows chefs to prepare multiple items simultaneously, enhancing productivity and efficiency.

The Pitco Frialator L20-332 incorporates advanced heating technology that ensures even heating throughout the oil. This unit utilizes a highly efficient gas burner system that optimizes energy consumption while delivering consistent frying temperatures. The ability to quickly recover heat after food is added ensures that cooks maintain optimal frying conditions without significant temperature drops, which is crucial for achieving perfectly cooked food.

Additionally, this fryer features a durable stainless steel exterior that not only enhances its aesthetic appeal but also makes it easy to clean and maintain. The stainless steel construction resists rust and corrosion, ensuring longevity even in the busiest kitchen environments. Its adjustable legs allow for easy installation and adaptability to various kitchen layouts.

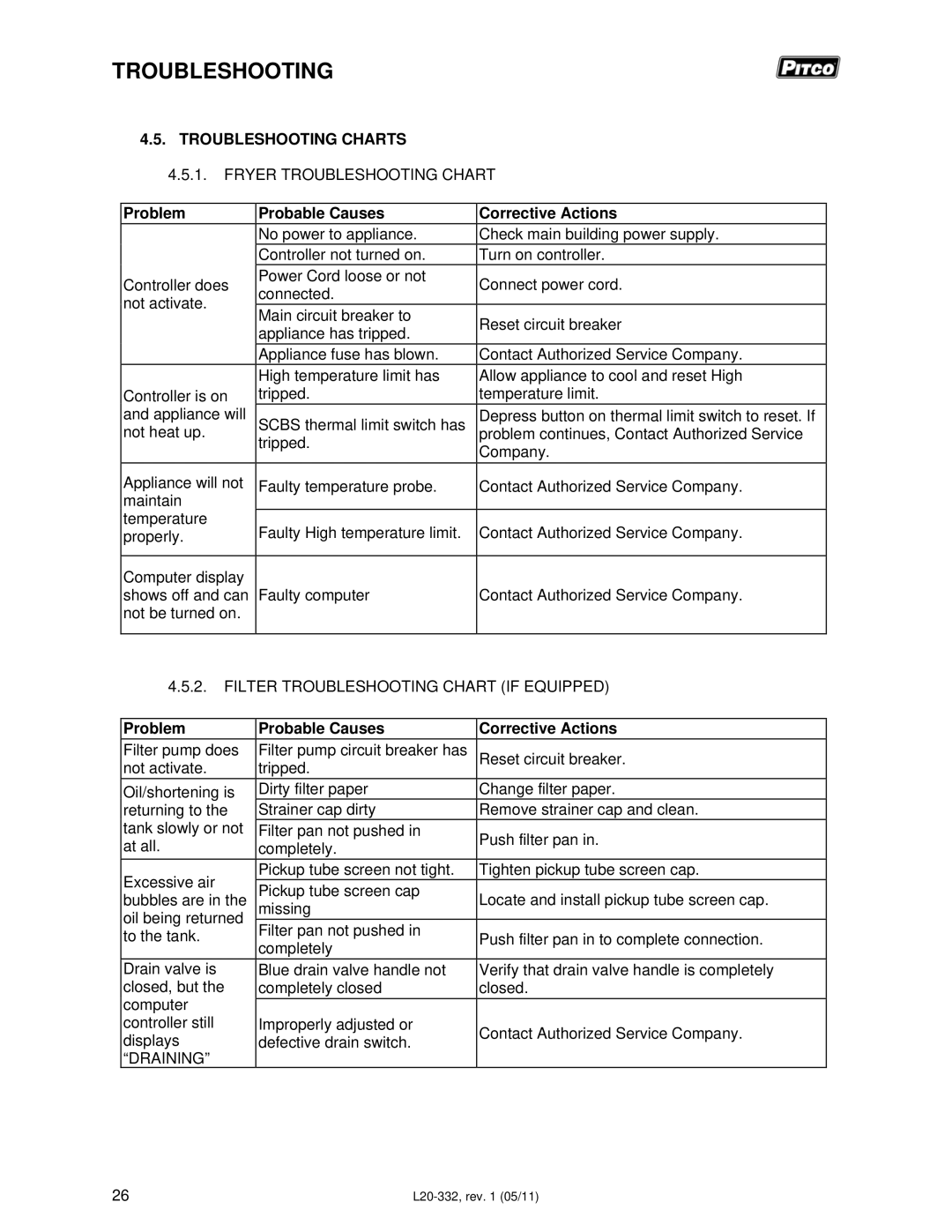

Safety is paramount in any commercial kitchen, and the L20-332 addresses this with effective features such as an integrated high-limit temperature control and a manual reset for safe operation. An easily accessible drain valve simplifies oil changes and maintenance, allowing for efficient cleaning routines.

Easy-to-use controls provide operators with precise temperature settings and cooking times, ensuring consistency and quality in every dish. The design of the fryer also includes a built-in filtration system that extends oil life and boosts the flavor of fried products, resulting in cost savings for the business.

In summary, the Pitco Frialator L20-332 is a powerful and reliable deep fryer equipped with advanced features designed for high-volume cooking. Its combination of efficient heating technology, user-friendly controls, and durable materials make it an ideal addition to any commercial kitchen looking to maximize productivity while delivering exceptional food quality.