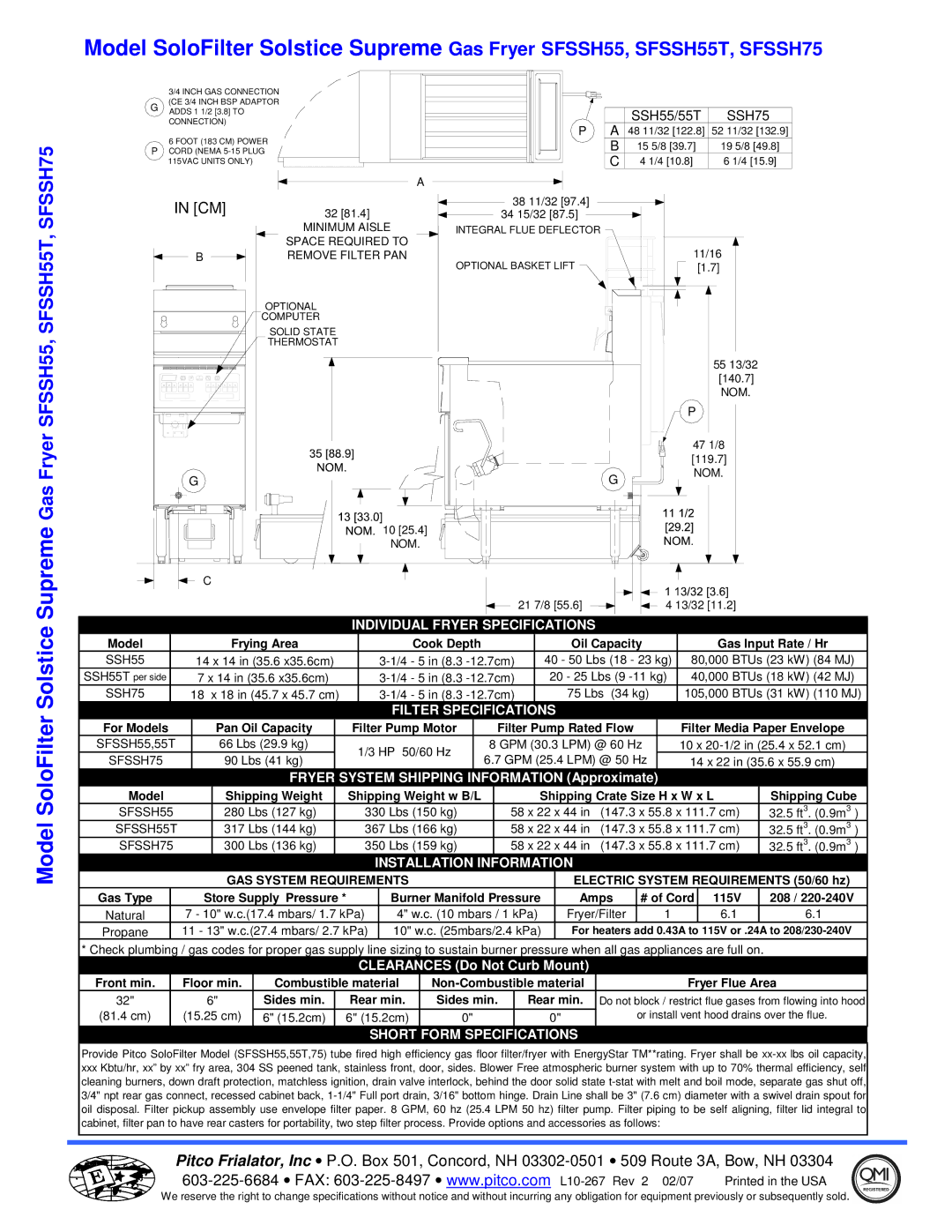

SFSSH75, SFSSH55T, SFSSH55 specifications

The Pitco Frialator SFSSH series, which includes models SFSSH55T, SFSSH55, and SFSSH75, represents a pinnacle of design and technology in commercial frying equipment. Known for their performance, versatility, and efficiency, these fryers are ideal for a broad range of foodservice applications, from casual dining to bustling commercial kitchens.One of the standout features of the SFSSH series is their Smart Set control technology, which offers advanced programming capabilities. This system allows users to calibrate cooking times and temperatures to achieve perfect fry results consistently. This feature is particularly beneficial for establishments that require uniformity across large quantities of fried food, as it minimizes the chances of human error during the cooking process.

Each model in the SFSSH series is equipped with a high-efficiency burner system that minimizes energy consumption while maximizing output. The burners are designed to ensure uniform heat distribution, providing consistent frying across all food items. This efficient heating not only improves cooking times but also enhances the quality of the fried product by ensuring that items cook evenly and maintain their intended texture and flavor.

The durability of Pitco fryers is another significant characteristic. The SFSSH series is constructed with heavy-duty stainless steel, ensuring longevity and ease of maintenance. The fryers are built to withstand the rigors of a busy kitchen, featuring welded and reinforced seams, making them robust against the daily wear and tear typically faced in commercial environments.

Safety and ease of use are paramount in the design of the SFSSH series. Each fryer comes with a built-in oil filtration system, which extends the life of the oil and enhances the overall quality of the fried foods. The filtration system operates while the fryers are in operation, ensuring a cleaner frying environment and reducing the frequency of oil changes.

Furthermore, the fryers feature a front-mounted drain, allowing for quick and easy oil changes. This design not only saves time but also improves the cleanliness and efficiency of the kitchen operation.

In summary, the Pitco Frialator SFSSH55T, SFSSH55, and SFSSH75 encapsulate the functionality, reliability, and efficiency required by modern foodservice establishments. With their advanced technology, robust design, and user-friendly features, these fryers stand as an excellent investment for any commercial kitchen seeking to deliver high-quality fried items consistently.