Drawer |

|

|

|

|

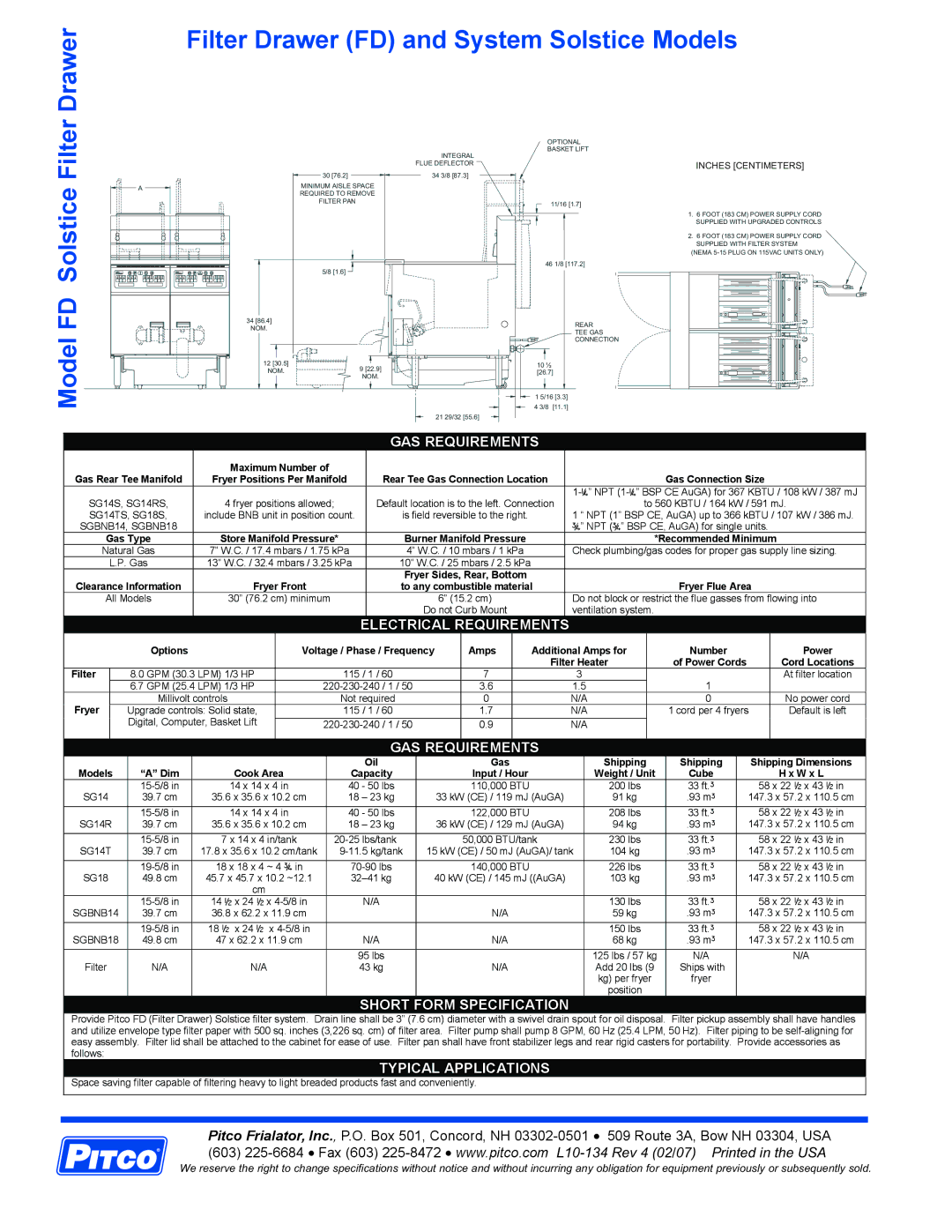

| Filter Drawer (FD) and System Solstice Models | |||||

|

|

|

|

|

|

|

|

|

|

| |

Filter |

|

|

|

|

|

|

|

|

| OPTIONAL | |

|

|

|

|

|

|

|

|

| BASKET LIFT | ||

|

|

|

|

|

|

|

|

| INTEGRAL |

| |

|

|

|

|

|

|

|

|

| FLUE DEFLECTOR | INCHES [CENTIMETERS] | |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| 30 [76.2] | 34 3/8 [87.3] |

| |

Solstice |

|

| A |

|

|

|

|

| MINIMUM AISLE SPACE |

|

|

|

|

|

|

|

|

| REQUIRED TO REMOVE |

|

| ||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| FILTER PAN |

| 11/16 [1.7] | |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| 1. 6 FOOT (183 CM) POWER SUPPLY CORD | |

|

|

|

|

|

|

|

|

|

| SUPPLIED WITH UPGRADED CONTROLS | |

|

|

|

|

|

|

|

|

|

| 2. 6 FOOT (183 CM) POWER SUPPLY CORD | |

|

|

|

|

|

|

|

|

|

| SUPPLIED WITH FILTER SYSTEM | |

|

|

|

|

|

|

|

|

|

| (NEMA | |

|

|

|

|

|

|

|

|

| 46 1/8 [117.2] | ||

|

|

|

|

|

|

|

| 5/8 [1.6] |

|

| |

L 1 2 | 3 4 5 | 6 7 8 | 9 0 R | L 1 2 | 3 4 5 | 6 7 8 | 9 0 R |

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

FD |

|

|

|

|

|

|

| 34 [86.4] |

|

| REAR |

|

|

|

|

|

|

| NOM. |

|

| ||

|

|

|

|

|

|

|

|

|

| ||

Model |

|

|

|

|

|

|

|

|

|

| TEE GAS |

|

|

|

|

|

|

|

|

|

| CONNECTION | |

|

|

|

|

|

|

| 12 [30.5] | 9 [22.9] | 10 ½ | ||

|

|

|

|

|

|

| NOM. | ||||

|

|

|

|

|

|

| [26.7] | ||||

|

|

|

|

|

|

| NOM. | ||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| 1 5/16 [3.3] | ||

|

|

|

|

|

|

|

|

| 4 3/8 | [11.1] | |

|

|

|

|

|

|

|

|

|

| 21 29/32 [55.6] |

|

GAS REQUIREMENTS

|

|

| Maximum Number of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Gas Rear Tee Manifold | Fryer Positions Per Manifold |

| Rear Tee Gas Connection Location |

|

|

|

|

| Gas Connection Size | |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

SG14S, SG14RS, | 4 fryer positions allowed; |

| Default location is to the left. Connection |

|

|

| to 560 KBTU / 164 kW / 591 mJ. | |||||||||||||||||

SG14TS, SG18S, | include BNB unit in position count. |

| is field reversible to the right. |

|

| 1 “ NPT (1” BSP CE, AuGA) up to 366 kBTU / 107 kW / 386 mJ. | ||||||||||||||||||

SGBNB14, SGBNB18 |

|

|

|

|

|

|

|

|

|

|

|

|

| ¾” NPT (¾” BSP CE, AuGA) for single units. | ||||||||||

Gas Type | Store Manifold Pressure* |

|

| Burner Manifold Pressure |

|

|

|

|

| *Recommended Minimum | ||||||||||||||

Natural Gas | 7” W.C. / 17.4 mbars / 1.75 kPa |

| 4” W.C. / 10 mbars / 1 kPa |

|

| Check plumbing/gas codes for proper gas supply line sizing. | ||||||||||||||||||

L.P. Gas | 13” W.C. / 32.4 mbars / 3.25 kPa |

| 10” W.C. / 25 mbars / 2.5 kPa |

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

| Fryer Sides, Rear, Bottom |

|

|

|

|

|

|

|

|

|

|

| ||||

Clearance Information | Fryer Front |

|

|

|

| to any combustible material |

|

|

|

|

| Fryer Flue Area | ||||||||||||

All Models | 30” (76.2 cm) minimum |

|

|

|

| 6” (15.2 cm) |

|

| Do not block or restrict the flue gasses from flowing into | |||||||||||||||

|

|

|

|

|

|

|

|

|

| Do not Curb Mount |

|

| ventilation system. |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| ELECTRICAL REQUIREMENTS |

|

|

|

|

|

|

|

|

|

| ||||||

|

| Options |

| Voltage / Phase / Frequency |

| Amps |

| Additional Amps for |

| Number |

|

| Power | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Filter Heater |

| of Power Cords |

|

| Cord Locations | |||||

Filter |

| 8.0 GPM (30.3 LPM) 1/3 HP |

| 115 / 1 / 60 |

|

|

| 7 |

|

|

| 3 |

|

|

| 1 |

|

|

| At filter location | ||||

|

| 6.7 GPM (25.4 LPM) 1/3 HP |

|

|

| 3.6 |

|

|

| 1.5 |

|

|

|

|

|

| ||||||||

Fryer |

| Millivolt controls |

|

| Not required |

|

|

| 0 |

|

|

| N/A |

|

| 0 |

|

|

| No power cord | ||||

| Upgrade controls: Solid state, |

| 115 / 1 / 60 |

|

|

| 1.7 |

|

|

| N/A |

|

| 1 cord per 4 fryers |

| Default is left | ||||||||

|

| Digital, Computer, Basket Lift |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

| 0.9 |

|

|

| N/A |

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| GAS REQUIREMENTS |

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| Oil |

|

|

| Gas |

|

|

|

| Shipping | Shipping |

|

| Shipping Dimensions | ||||

Models | “A” Dim | Cook Area |

|

| Capacity |

|

|

| Input / Hour |

|

|

|

| Weight / Unit | Cube |

|

|

| H x W x L | |||||

|

| 14 x 14 x 4 in |

|

| 40 - 50 lbs |

|

|

| 110,000 BTU |

|

|

|

| 200 lbs | 33 ft.³ |

|

| 58 x 22 ½ x 43 ½ in | ||||||

SG14 | 39.7 cm | 35.6 x 35.6 x 10.2 cm |

|

| 18 – 23 kg |

|

| 33 kW (CE) / 119 mJ (AuGA) |

|

| 91 kg | .93 m³ |

| 147.3 x 57.2 x 110.5 cm | ||||||||||

|

| 14 x 14 x 4 in |

|

| 40 - 50 lbs |

|

|

| 122,000 BTU |

|

|

|

| 208 lbs | 33 ft.³ |

|

| 58 x 22 ½ x 43 ½ in | ||||||

SG14R | 39.7 cm | 35.6 x 35.6 x 10.2 cm |

|

| 18 – 23 kg |

|

| 36 kW (CE) / 129 mJ (AuGA) |

|

| 94 kg | .93 m³ |

| 147.3 x 57.2 x 110.5 cm | ||||||||||

|

| 7 x 14 x 4 in/tank |

|

|

|

| 50,000 BTU/tank |

|

| 230 lbs | 33 ft.³ |

|

| 58 x 22 ½ x 43 ½ in | ||||||||||

SG14T | 39.7 cm | 17.8 x 35.6 x 10.2 cm/tank |

| 15 kW (CE) / 50 mJ (AuGA)/ tank |

| 104 kg | .93 m³ |

| 147.3 x 57.2 x 110.5 cm | |||||||||||||||

|

| 18 x 18 x 4 ~ 4 ¾ in |

|

|

|

|

| 140,000 BTU |

|

|

|

| 226 lbs | 33 ft.³ |

|

| 58 x 22 ½ x 43 ½ in | |||||||

SG18 | 49.8 cm | 45.7 x 45.7 x 10.2 ~12.1 |

|

|

| 40 kW (CE) / 145 mJ ((AuGA) |

|

| 103 kg | .93 m³ |

| 147.3 x 57.2 x 110.5 cm | ||||||||||||

|

|

| cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| 14 ½ x 24 ½ x |

|

| N/A |

|

|

|

|

|

|

|

|

| 130 lbs | 33 ft.³ |

|

| 58 x 22 ½ x 43 ½ in | |||||

SGBNB14 | 39.7 cm | 36.8 x 62.2 x 11.9 cm |

|

|

|

|

|

|

| N/A |

|

|

|

| 59 kg | .93 m³ |

| 147.3 x 57.2 x 110.5 cm | ||||||

|

| 18 ½ x 24 ½ x |

|

|

|

|

|

|

|

|

|

|

|

|

| 150 lbs | 33 ft.³ |

|

| 58 x 22 ½ x 43 ½ in | ||||

SGBNB18 | 49.8 cm | 47 x 62.2 x 11.9 cm |

|

| N/A |

|

|

| N/A |

|

|

|

| 68 kg | .93 m³ |

| 147.3 x 57.2 x 110.5 cm | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| 95 lbs |

|

|

|

|

|

|

|

|

| 125 lbs / 57 kg | N/A |

|

|

| N/A | ||

Filter | N/A | N/A |

|

| 43 kg |

|

|

| N/A |

|

|

|

| Add 20 lbs (9 | Ships with |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| kg) per fryer | fryer |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| position |

|

|

|

|

| |

SHORT FORM SPECIFICATION

Provide Pitco FD (Filter Drawer) Solstice filter system. Drain line shall be 3” (7.6 cm) diameter with a swivel drain spout for oil disposal. Filter pickup assembly shall have handles and utilize envelope type filter paper with 500 sq. inches (3,226 sq. cm) of filter area. Filter pump shall pump 8 GPM, 60 Hz (25.4 LPM, 50 Hz). Filter piping to be

TYPICAL APPLICATIONS

Space saving filter capable of filtering heavy to light breaded products fast and conveniently.

Pitco Frialator, Inc., P.O. Box 501, Concord, NH

We reserve the right to change specifications without notice and without incurring any obligation for equipment previously or subsequently sold.