DISASSEMBLY

HANDLE

Should the throttle valve seal 847426, need replacing, unscrew the throttle valve cap 867753, for removal of the throttle valve and components.

The tool is equipped with an air screen for protection of the internal motor parts from foreign material. The air screen located in the inlet bushing may be removed for cleaning and inspection by unscrewing the inlet bushing 867758. If the screen is torn or damaged, the inlet bushing should be replaced. The throttle handle and motor housing, may be removed for cleaning and inspection by unscrewing the two

(2)socket head cap screws and nuts after the tool is disassembled to the point that the motor can be removed to allow access to nuts inside motor housing.

MOTOR HOUSING & MOTOR

The front housing and intermediate plate 204683, must be removed from motor housing to remove motor. Remove four (4) hex cap screws holding the front housing and intermediate plate to motor housing. The motor can be pulled from motor housing. The

Use a suitable driver to drive the front rotor shaft out of the front rotor bearing. After removing the cylinder and rotor blades, the rear rotor shaft may be driven out of the rear rotor bearing.

FRONT HOUSING & INTERMEDIATE PLATE

To disassemble the front housing 204692, from the inter- mediate plate 204683, remove (4) four hex cap screws and lift complete unit off the intermediate plate. The secondary muffler can be removed for inspection.

REASSEMBLY

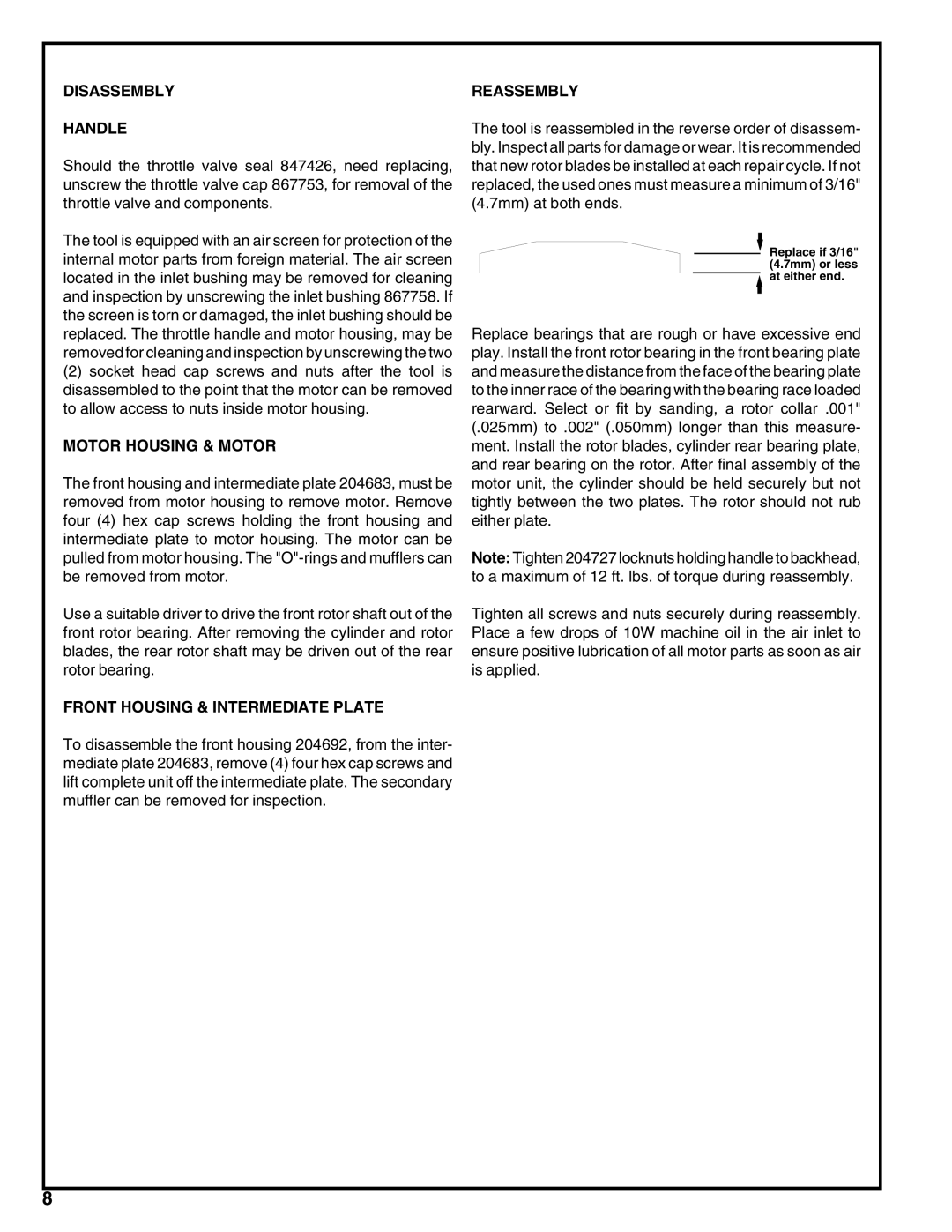

The tool is reassembled in the reverse order of disassem- bly. Inspect all parts for damage or wear. It is recommended that new rotor blades be installed at each repair cycle. If not replaced, the used ones must measure a minimum of 3/16" (4.7mm) at both ends.

Replace if 3/16" (4.7mm) or less at either end.

Replace bearings that are rough or have excessive end play. Install the front rotor bearing in the front bearing plate and measure the distance from the face of the bearing plate to the inner race of the bearing with the bearing race loaded rearward. Select or fit by sanding, a rotor collar .001" (.025mm) to .002" (.050mm) longer than this measure- ment. Install the rotor blades, cylinder rear bearing plate, and rear bearing on the rotor. After final assembly of the motor unit, the cylinder should be held securely but not tightly between the two plates. The rotor should not rub either plate.

Note: Tighten 204727 locknuts holding handle to backhead, to a maximum of 12 ft. lbs. of torque during reassembly.

Tighten all screws and nuts securely during reassembly. Place a few drops of 10W machine oil in the air inlet to ensure positive lubrication of all motor parts as soon as air is applied.

8