|

|

|

Fig.17 |

| Fig. 18 |

CROSS-CUTTING

Cutting directly across the grain of a piece of lumber is called crosscutting. Position the work so that the cut will be on the left.

RIPPING

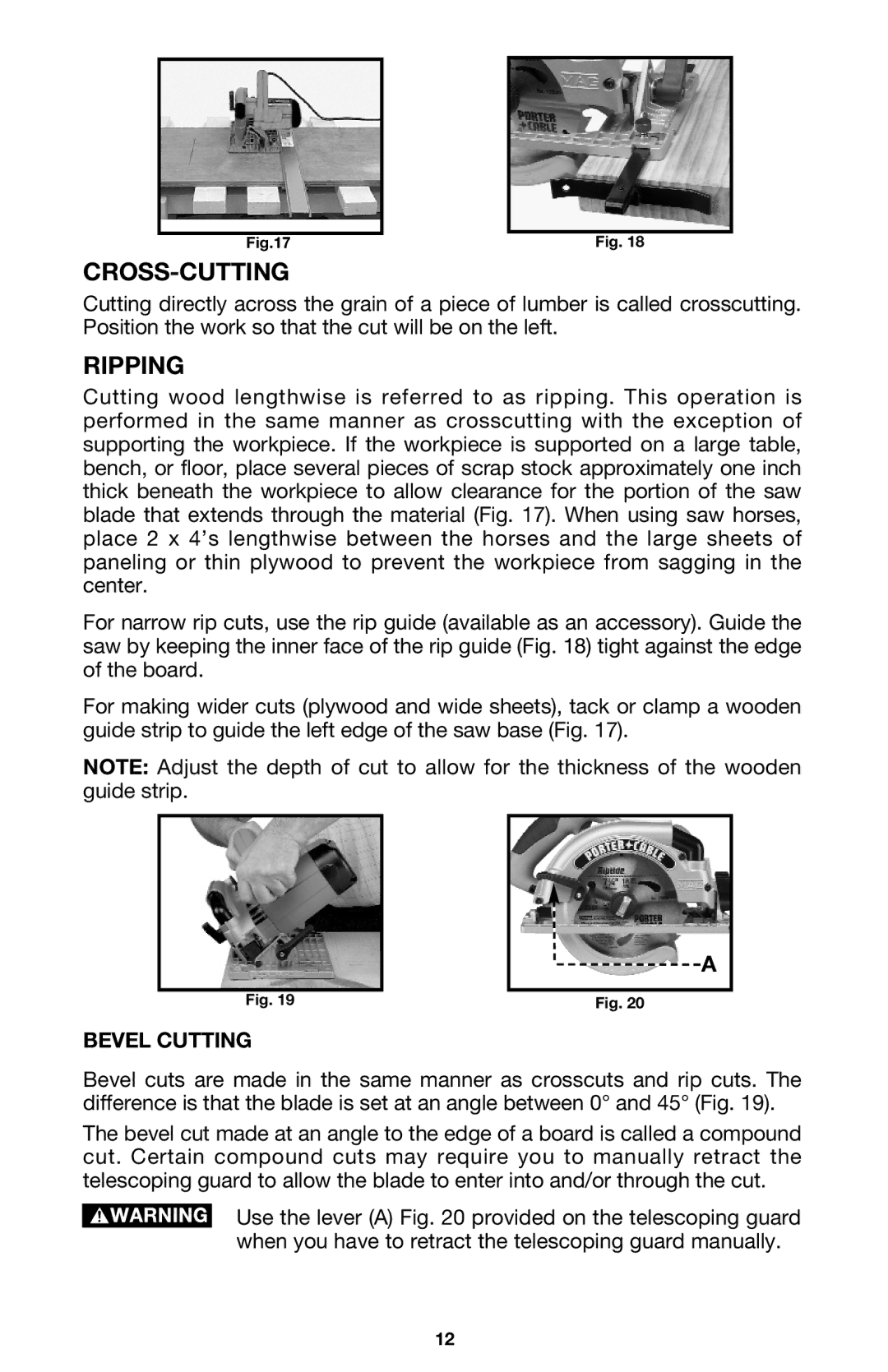

Cutting wood lengthwise is referred to as ripping. This operation is performed in the same manner as crosscutting with the exception of supporting the workpiece. If the workpiece is supported on a large table, bench, or floor, place several pieces of scrap stock approximately one inch thick beneath the workpiece to allow clearance for the portion of the saw blade that extends through the material (Fig. 17). When using saw horses, place 2 x 4’s lengthwise between the horses and the large sheets of paneling or thin plywood to prevent the workpiece from sagging in the center.

For narrow rip cuts, use the rip guide (available as an accessory). Guide the saw by keeping the inner face of the rip guide (Fig. 18) tight against the edge of the board.

For making wider cuts (plywood and wide sheets), tack or clamp a wooden guide strip to guide the left edge of the saw base (Fig. 17).

NOTE: Adjust the depth of cut to allow for the thickness of the wooden guide strip.

A

Fig. 19 | Fig. 20 |

BEVEL CUTTING

Bevel cuts are made in the same manner as crosscuts and rip cuts. The difference is that the blade is set at an angle between 0° and 45° (Fig. 19).

The bevel cut made at an angle to the edge of a board is called a compound cut. Certain compound cuts may require you to manually retract the telescoping guard to allow the blade to enter into and/or through the cut.

Use the lever (A) Fig. 20 provided on the telescoping guard when you have to retract the telescoping guard manually.

12