8.At a slow, steady pace, push tool forward in base as far as depth stop allows.

9.Release trigger switch to stop tool and remove tool from work.

10.Repeat steps 5 through 8 until all the grooves in workpiece “A” are completed.

11.Follow steps 3 through 10 of CORNER JOINTS Section to complete required grooves in workpiece “B” Fig. 23.

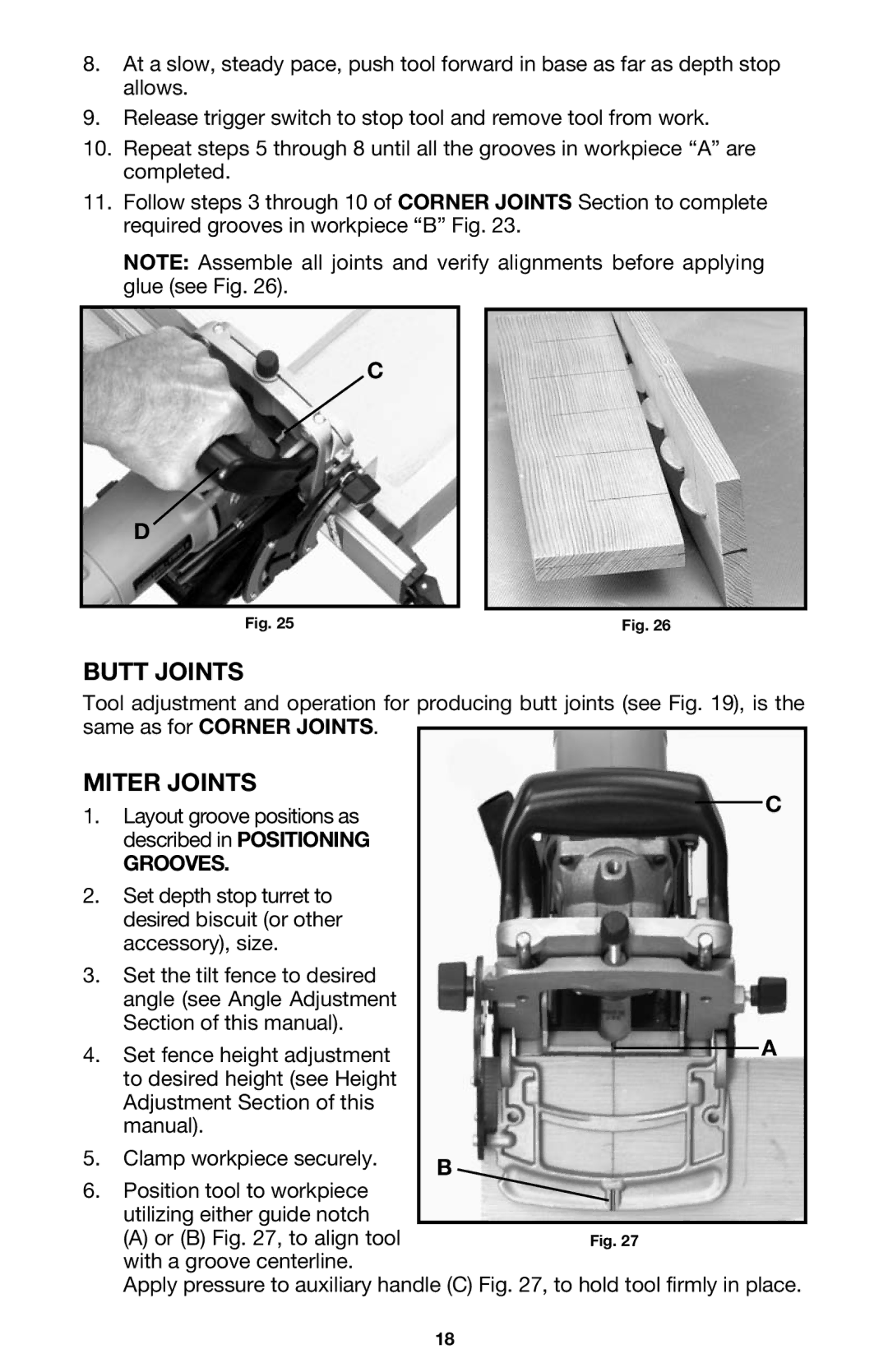

NOTE: Assemble all joints and verify alignments before applying glue (see Fig. 26).

C

D

Fig. 25 | Fig. 26 |

BUTT JOINTS

Tool adjustment and operation for producing butt joints (see Fig. 19), is the same as for CORNER JOINTS.

MITER JOINTS |

|

| C | |

1. | Layout groove positions as |

|

| |

|

|

| ||

| described in POSITIONING |

|

|

|

| GROOVES. |

|

|

|

2. | Set depth stop turret to |

|

|

|

| desired biscuit (or other |

|

|

|

| accessory), size. |

|

|

|

3. | Set the tilt fence to desired |

|

|

|

| angle (see Angle Adjustment |

|

|

|

| Section of this manual). |

| A | |

4. | Set fence height adjustment |

| ||

| to desired height (see Height |

|

|

|

| Adjustment Section of this |

|

|

|

| manual). |

|

|

|

5. | Clamp workpiece securely. | B | ||

|

| |||

6.Position tool to workpiece utilizing either guide notch

(A) or (B) Fig. 27, to align tool with a groove centerline.

Apply pressure to auxiliary handle (C) Fig. 27, to hold tool firmly in place.

18