MACHINE USE

NOTE: Your Drill Press should be used with drill bits 5/8″ or less in diameter.

The following directions will give the inexperienced operator a start on common drill press operations. Use scrap material for practice to get a feel of the machine before attempting regular work.

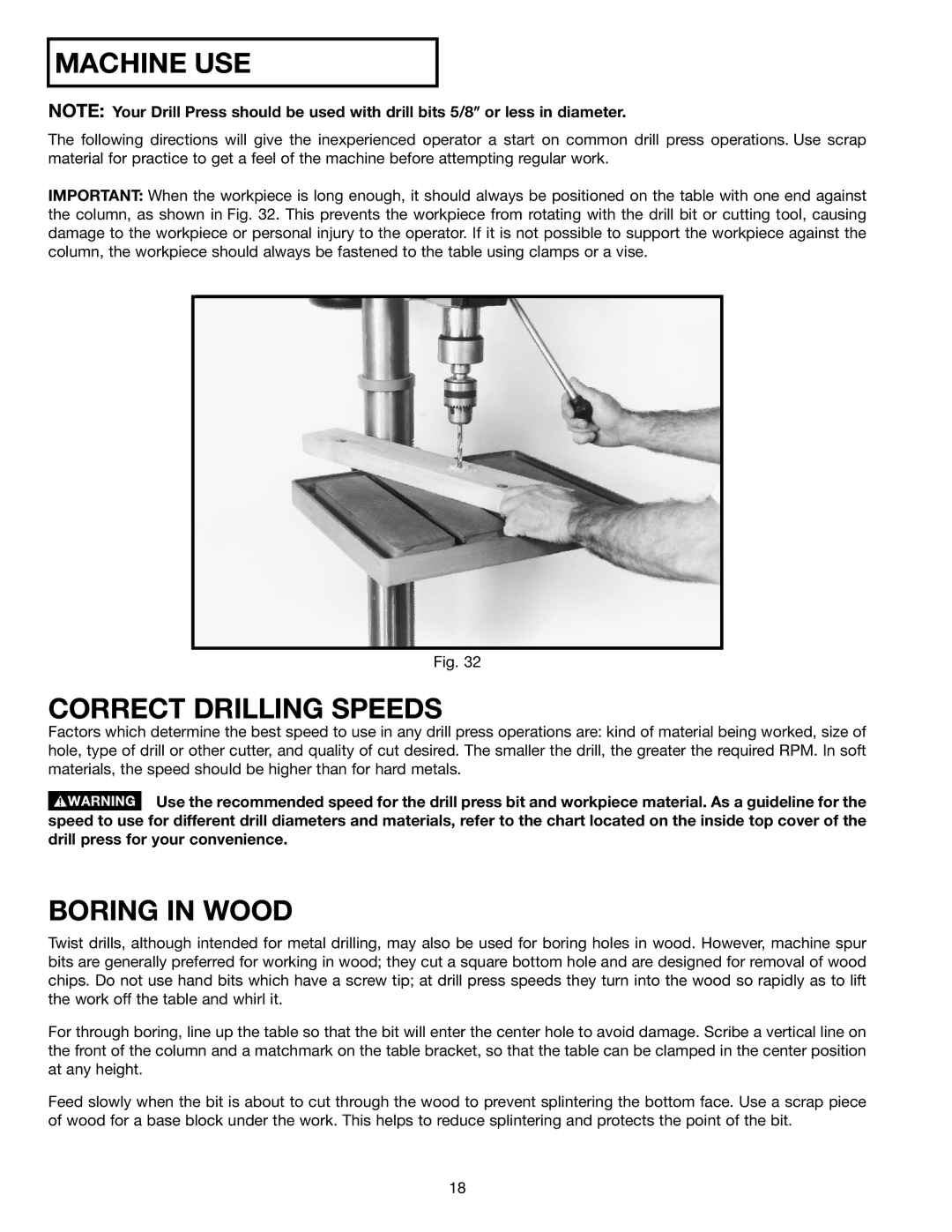

IMPORTANT: When the workpiece is long enough, it should always be positioned on the table with one end against the column, as shown in Fig. 32. This prevents the workpiece from rotating with the drill bit or cutting tool, causing damage to the workpiece or personal injury to the operator. If it is not possible to support the workpiece against the column, the workpiece should always be fastened to the table using clamps or a vise.

Fig. 32

CORRECT DRILLING SPEEDS

Factors which determine the best speed to use in any drill press operations are: kind of material being worked, size of hole, type of drill or other cutter, and quality of cut desired. The smaller the drill, the greater the required RPM. In soft materials, the speed should be higher than for hard metals.

![]() Use the recommended speed for the drill press bit and workpiece material. As a guideline for the speed to use for different drill diameters and materials, refer to the chart located on the inside top cover of the drill press for your convenience.

Use the recommended speed for the drill press bit and workpiece material. As a guideline for the speed to use for different drill diameters and materials, refer to the chart located on the inside top cover of the drill press for your convenience.

BORING IN WOOD

Twist drills, although intended for metal drilling, may also be used for boring holes in wood. However, machine spur bits are generally preferred for working in wood; they cut a square bottom hole and are designed for removal of wood chips. Do not use hand bits which have a screw tip; at drill press speeds they turn into the wood so rapidly as to lift the work off the table and whirl it.

For through boring, line up the table so that the bit will enter the center hole to avoid damage. Scribe a vertical line on the front of the column and a matchmark on the table bracket, so that the table can be clamped in the center position at any height.

Feed slowly when the bit is about to cut through the wood to prevent splintering the bottom face. Use a scrap piece of wood for a base block under the work. This helps to reduce splintering and protects the point of the bit.

18