TO START AND STOP THE MODEL 7429

Make sure that the switch is "OFF" and power circuit voltage is the same as that shown on the specification plate.

1.Connect the tool to the power source.

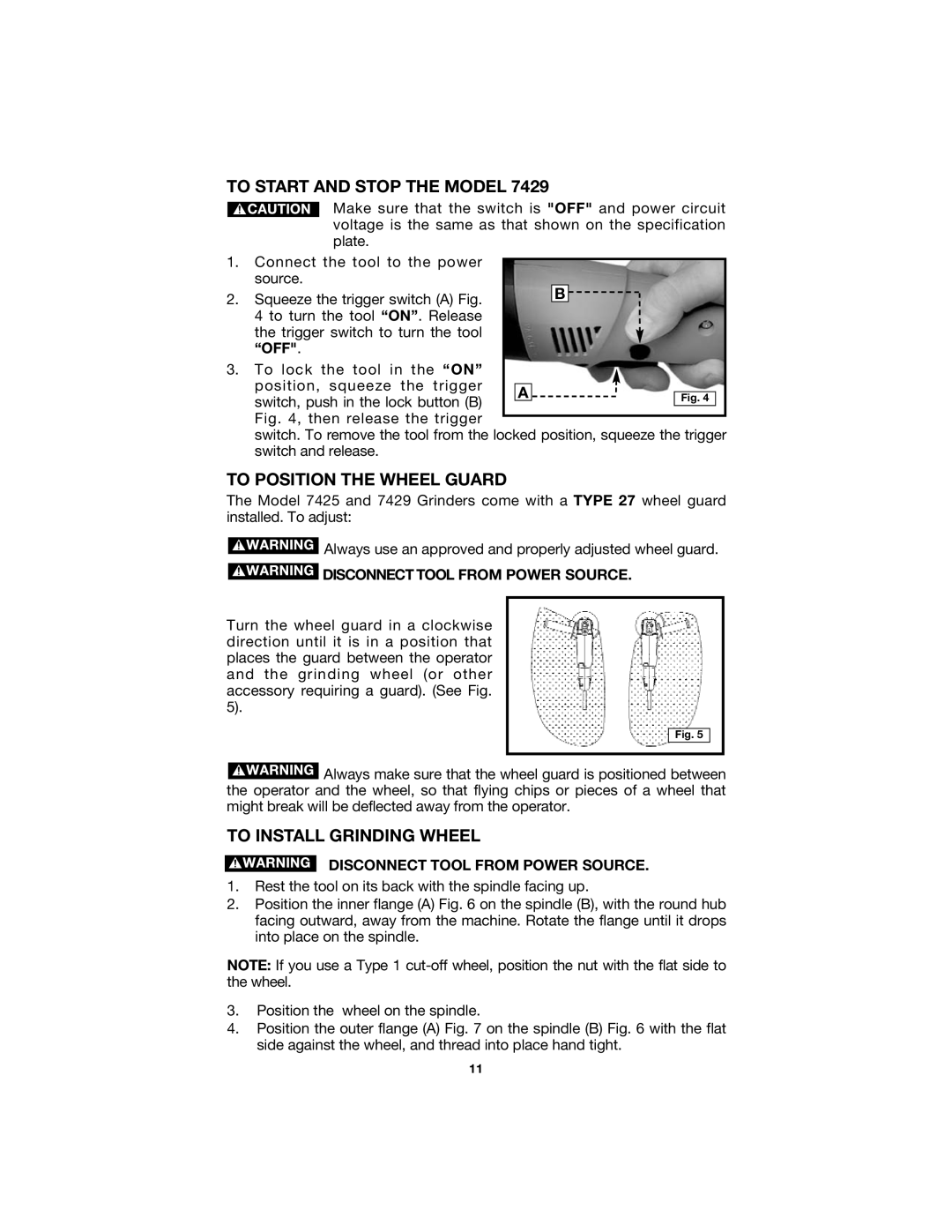

2. Squeeze the trigger switch (A) Fig. | B |

| |

4 to turn the tool “ON”. Release |

|

the trigger switch to turn the tool |

|

“OFF". |

|

3.To lock the tool in the “ON”

position, squeeze the trigger |

|

|

|

|

|

| A |

|

|

| |

switch, push in the lock button (B) |

|

| Fig. 4 |

| |

|

|

|

| ||

|

|

|

|

| |

Fig. 4, then release the trigger |

|

|

|

|

|

|

|

|

|

|

switch. To remove the tool from the locked position, squeeze the trigger switch and release.

TO POSITION THE WHEEL GUARD

The Model 7425 and 7429 Grinders come with a TYPE 27 wheel guard installed. To adjust:

![]() Always use an approved and properly adjusted wheel guard.

Always use an approved and properly adjusted wheel guard.

DISCONNECT TOOL FROM POWER SOURCE.

DISCONNECT TOOL FROM POWER SOURCE.

Turn the wheel guard in a clockwise direction until it is in a position that places the guard between the operator and the grinding wheel (or other accessory requiring a guard). (See Fig. 5).

Fig. 5

![]() Always make sure that the wheel guard is positioned between the operator and the wheel, so that flying chips or pieces of a wheel that might break will be deflected away from the operator.

Always make sure that the wheel guard is positioned between the operator and the wheel, so that flying chips or pieces of a wheel that might break will be deflected away from the operator.

TO INSTALL GRINDING WHEEL

DISCONNECT TOOL FROM POWER SOURCE.

1.Rest the tool on its back with the spindle facing up.

2.Position the inner flange (A) Fig. 6 on the spindle (B), with the round hub facing outward, away from the machine. Rotate the flange until it drops into place on the spindle.

NOTE: If you use a Type 1

3.Position the wheel on the spindle.

4.Position the outer flange (A) Fig. 7 on the spindle (B) Fig. 6 with the flat side against the wheel, and thread into place hand tight.

11