894884-003, BN200A specifications

The Porter-Cable BN200A is a versatile and compact brad nailer, designed to meet the demands of both professional contractors and DIY enthusiasts. As part of Porter-Cable's renowned lineup, the BN200A combines precision, power, and user-friendly features, making it an excellent choice for a variety of woodworking and construction projects.One of the standout features of the BN200A is its lightweight design. Weighing only about 2.5 pounds, this brad nailer is easy to handle, reducing user fatigue during extended use. Its compact frame allows for excellent maneuverability, making it particularly useful in tight spaces or when working on intricate projects.

The brad nailer is powered by an efficient electric motor, which provides dependable performance without the need for an air compressor or gas canister. This means that users can enjoy the flexibility of using the BN200A anywhere, with minimal setup time. Its capability to drive 18-gauge nails ranging from 5/8 inches to 2 inches in length adds to its versatility, enabling users to tackle a wide range of applications including trim work, cabinetry, and furniture assembly.

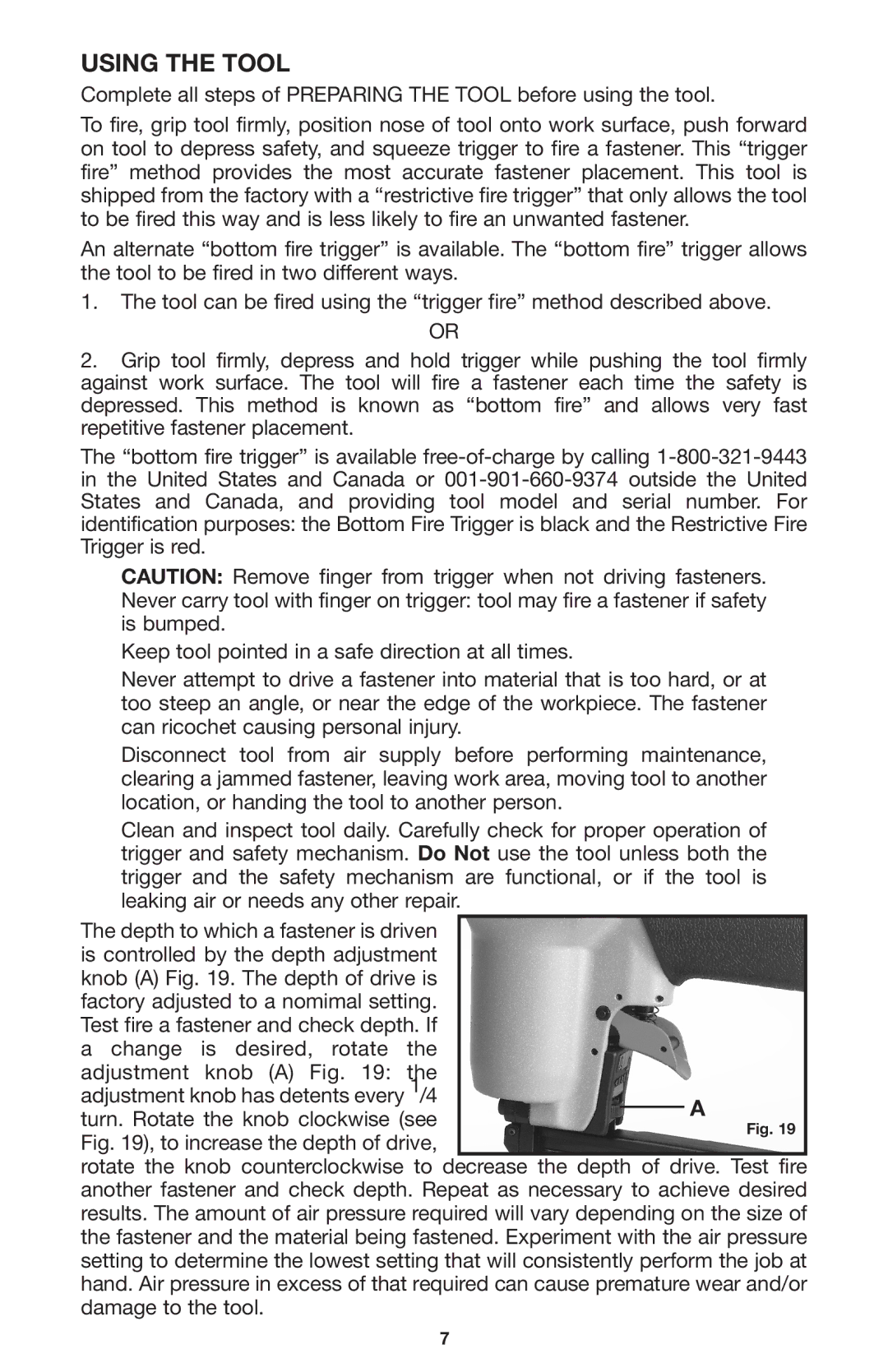

The BN200A features a tool-free depth adjustment system, allowing users to easily modify the nail depth for precise finish work. This is complemented by a clear plastic magazine that provides visibility to the nail supply, making it easy to monitor and reload when necessary. The quick-release jam clearing mechanism ensures that any nail jams can be resolved swiftly, minimizing downtime during projects.

Safety is also a prime consideration in the design of the BN200A. It comes equipped with a sequential firing mode, which allows for greater control during operation. Additionally, the integrated trigger lock helps prevent accidental firing, fostering a safer working environment.

Porter-Cable's BN200A is designed with durability in mind. Its robust construction can withstand the rigors of job site use, ensuring long-lasting performance. With a combination of features like an ergonomic grip, a lightweight build, and a reliable power source, the BN200A stands out as a top choice for those seeking a reliable and effective brad nailer for their projects. Whether you are a seasoned professional or a weekend warrior, the Porter-Cable BN200A is poised to deliver excellent results every time.