OPERATION

WARNING: | WORK | ROUTER |

Keep a firm grip on router with both hands at all times. Failure to do so could result in loss of control leading to possible serious injury.

ROUTING

Whenever you are routing a groove, your travel should be in a direction that places whatever guide you are using at the

STARTING AND ENDING A CUT

INTERNAL ROUTING

Tilt router and place on workpiece, letting edge of subbase contact workpiece first. Be careful not to let router bit contact workpiece. Turn router on and let motor build to its full speed. Gradually feed cutter into workpiece until subbase is level with workpiece.

Upon completion of cut, turn motor off and let it come to a complete stop before removing router from work surface.

![]() WARNING:

WARNING:

Never pull router out of work and place upside down on work surface before the cutter stops. Failure to do so could result in possible serious injury.

EDGING WITH PILOT BITS

The

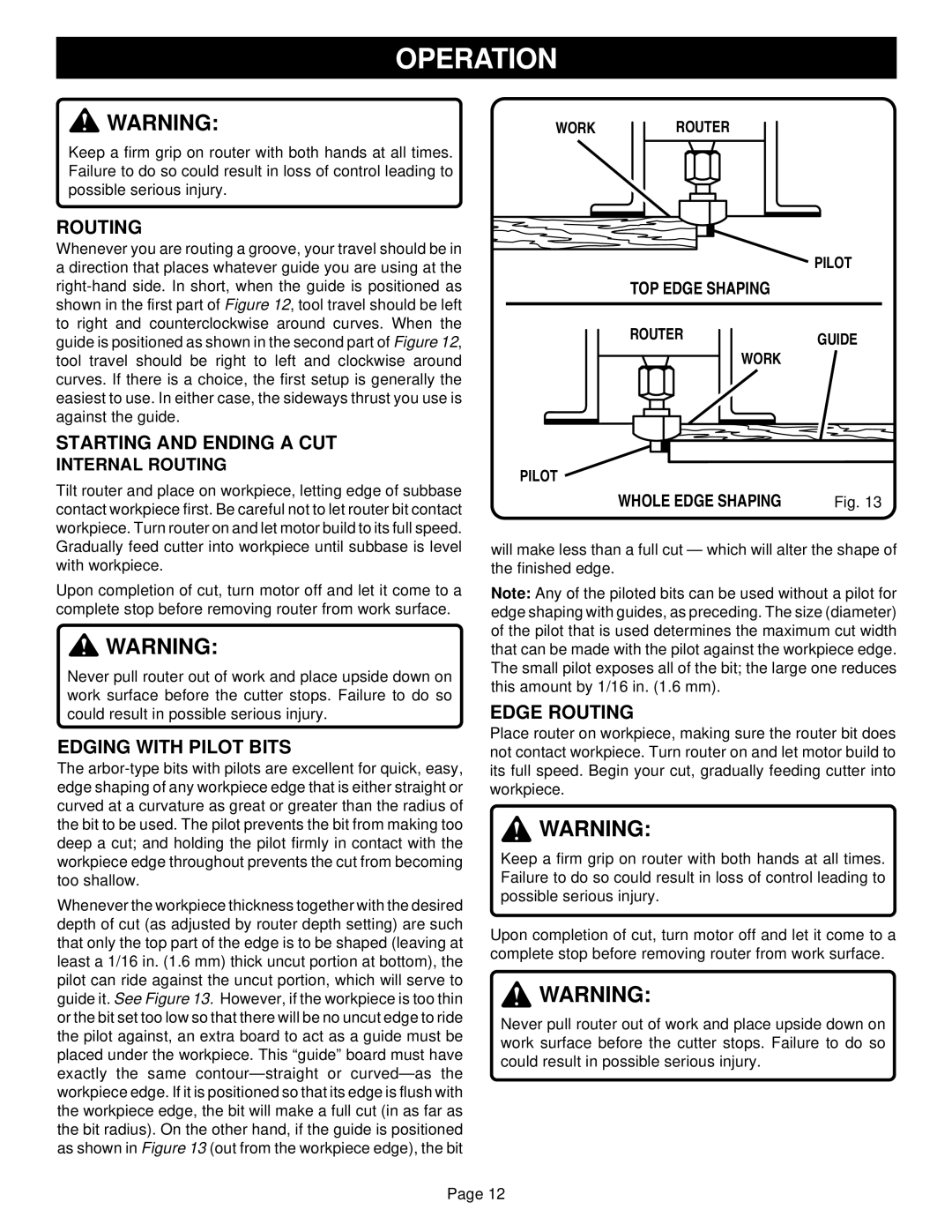

Whenever the workpiece thickness together with the desired depth of cut (as adjusted by router depth setting) are such that only the top part of the edge is to be shaped (leaving at least a 1/16 in. (1.6 mm) thick uncut portion at bottom), the pilot can ride against the uncut portion, which will serve to guide it. See Figure 13. However, if the workpiece is too thin or the bit set too low so that there will be no uncut edge to ride the pilot against, an extra board to act as a guide must be placed under the workpiece. This “guide” board must have exactly the same contour— straight or curved— as the workpiece edge. If it is positioned so that its edge is flush with the workpiece edge, the bit will make a full cut (in as far as the bit radius). On the other hand, if the guide is positioned as shown in Figure 13 (out from the workpiece edge), the bit

PILOT

TOP EDGE SHAPING

ROUTERGUIDE

WORK

PILOT

WHOLE EDGE SHAPING | Fig. 13 |

will make less than a full cut — which will alter the shape of the finished edge.

Note: Any of the piloted bits can be used without a pilot for edge shaping with guides, as preceding. The size (diameter) of the pilot that is used determines the maximum cut width that can be made with the pilot against the workpiece edge. The small pilot exposes all of the bit; the large one reduces this amount by 1/16 in. (1.6 mm).

EDGE ROUTING

Place router on workpiece, making sure the router bit does not contact workpiece. Turn router on and let motor build to its full speed. Begin your cut, gradually feeding cutter into workpiece.

![]() WARNING:

WARNING:

Keep a firm grip on router with both hands at all times. Failure to do so could result in loss of control leading to possible serious injury.

Upon completion of cut, turn motor off and let it come to a complete stop before removing router from work surface.

![]() WARNING:

WARNING:

Never pull router out of work and place upside down on work surface before the cutter stops. Failure to do so could result in possible serious injury.

Page 12