If the unit still doesn’t start, refer to TROUBLESHOOTING TABLE or call

OPERATING THE COUPLER

This model is equipped with a coupler which enables optional attachments to be installed. The optional attachments are:

MODEL:

Edger . . . . . . . . . . . . . . . . . . . . . . .1000E Cultivator . . . . . . . . . . . . . . . . . . .2000T Blower . . . . . . . . . . . . . . . . . . . . . .3000B Brushcutter . . . . . . . . . . . . . . . . . 4000C

![]() WARNING: Always stop unit and dis- connect spark plug before removing or instal- ling attachments.

WARNING: Always stop unit and dis- connect spark plug before removing or instal- ling attachments.

REMOVING TRIMMER ATTACH- MENT (OR OTHER OPTIONAL AT- TACHMENTS)

CAUTION: When removing or installing at- tachments, place the unit on a flat surface for stability.

1.Loosen the coupler by turning the knob counterclockwise.

Upper Tube

Coupler

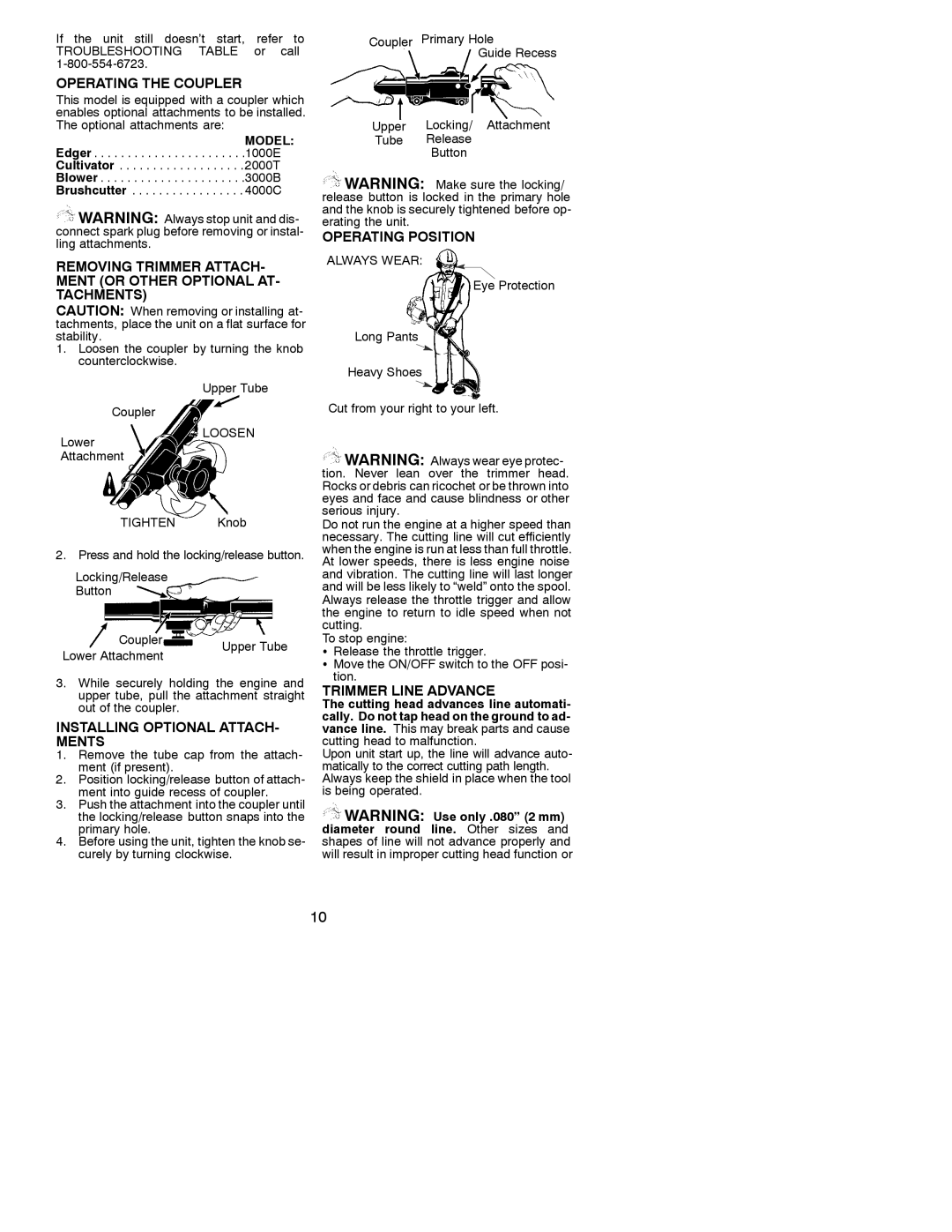

Coupler Primary Hole

Guide Recess

Upper Locking/ Attachment

Tube Release

Button

![]() WARNING: Make sure the locking/ release button is locked in the primary hole and the knob is securely tightened before op- erating the unit.

WARNING: Make sure the locking/ release button is locked in the primary hole and the knob is securely tightened before op- erating the unit.

OPERATING POSITION

ALWAYS WEAR:

Eye Protection

Long Pants

Heavy Shoes

Cut from your right to your left.

Lower

LOOSEN

AttachmentWARNING: Always wear eye protec- tion. Never lean over the trimmer head.

TIGHTEN Knob

Rocks or debris can ricochet or be thrown into eyes and face and cause blindness or other serious injury.

2. Press and hold the locking/release button.

Do not run the engine at a higher speed than necessary. The cutting line will cut efficiently when the engine is run at less than full throttle. At lower speeds, there is less engine noise

Locking/Release

Button

and vibration. The cutting line will last longer and will be less likely to “weld” onto the spool. Always release the throttle trigger and allow the engine to return to idle speed when not cutting.

Coupler | Upper Tube |

Lower Attachment |

To stop engine:

SRelease the throttle trigger.

3.While securely holding the engine and upper tube, pull the attachment straight out of the coupler.

SMove the ON/OFF switch to the OFF posi- tion.

TRIMMER LINE ADVANCE

INSTALLING OPTIONAL ATTACH-

MENTS

The cutting head advances line automati- cally. Do not tap head on the ground to ad- vance line. This may break parts and cause cutting head to malfunction.

1.Remove the tube cap from the attach- ment (if present).

2.Position locking/release button of attach- ment into guide recess of coupler.

3.Push the attachment into the coupler until the locking/release button snaps into the primary hole.

4.Before using the unit, tighten the knob se- curely by turning clockwise.

Upon unit start up, the line will advance auto- matically to the correct cutting path length. Always keep the shield in place when the tool is being operated.

![]() WARNING: Use only .080” (2 mm) diameter round line. Other sizes and shapes of line will not advance properly and will result in improper cutting head function or

WARNING: Use only .080” (2 mm) diameter round line. Other sizes and shapes of line will not advance properly and will result in improper cutting head function or

10