530087823 specifications

The Poulan 530087823 is a powerful and versatile chainsaw, well-regarded for its reliability and ease of use. Designed for both professional landscapers and homeowners, this model stands out with its user-friendly features and robust performance, making it an ideal tool for a variety of cutting tasks.One of the key features of the Poulan 530087823 is its 18-inch cutting bar, which allows for efficient cutting of larger logs and branches. This ample size strikes a balance between maneuverability and cutting capability, making it suitable for both trimming and heavier jobs. The chainsaw is powered by a dependable gas engine, which delivers the power necessary to tackle tough tasks with ease.

Equipped with advanced technologies, this model benefits from a patented air filtration system that ensures cleaner air intake, extending the life of the engine. This feature minimizes maintenance by reducing the frequency of filter changes, allowing users to focus on their work rather than upkeep. Additionally, the Poulan 530087823 incorporates an anti-vibration system that enhances the comfort of use; it reduces fatigue during extended cutting sessions, leading to improved accuracy and safety.

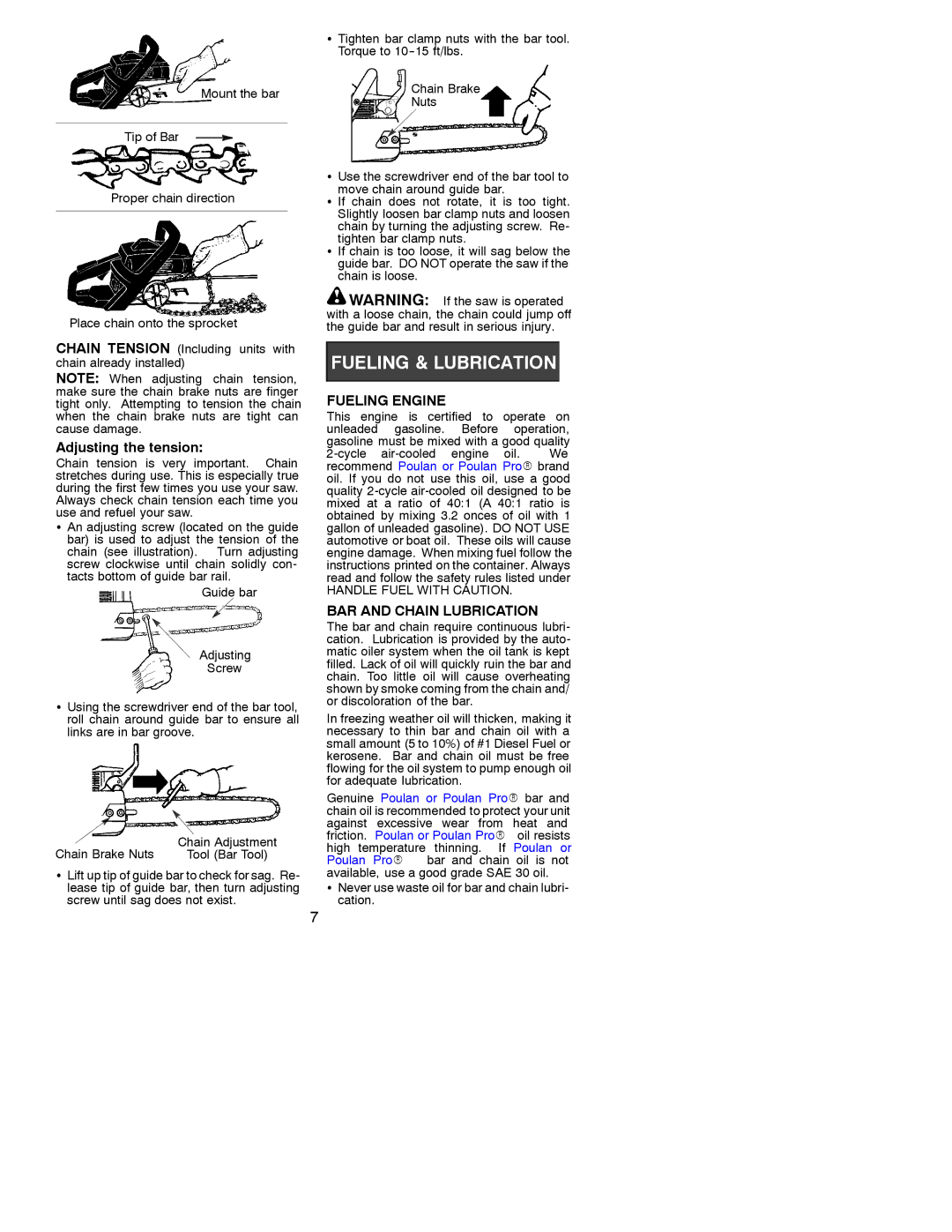

User convenience is emphasized by the chainsaw's tool-less chain adjustment system, which enables quick and hassle-free adjustments to the chain tension without the need for additional tools. This feature is particularly valuable during outdoor use, where convenience and efficiency are paramount. Moreover, the chainsaw features a primer bulb for easy starting, reducing the effort required to fire up the engine.

The Poulan 530087823 also comes with a safety chain brake, which is a critical feature in preventing accidents during operation. This brake system engages quickly in the event of kickback, stopping the chain immediately and enhancing user safety.

Overall, the Poulan 530087823 stands out due to its combination of powerful performance, user-friendly features, and a strong emphasis on safety. With its durable construction and advanced technologies, this chainsaw is a reliable choice for both casual users and professionals, capable of handling a wide range of cutting tasks effectively. Whether trimming branches or felling small trees, the Poulan 530087823 provides the performance and innovation needed to get the job done.