Cleaning the air filter:

A dirty air filter decreases engine perform- ance and increases fuel consumption and harmful emissions. Always clean after 15 tanks of fuel or 5 hours of operation, which- ever comes first. Clean more frequently in dusty conditions. A used aire filter can never be completely cleaned. It is advisable to re- place your air filter with a new one after every 50 hours of operation, or annually, whichever comes first.

1.Loosen 3 screws on cylinder cover.

2.Remove cylinder cover.

3.Remove air filter.

4.Clean the air filter using hot soapy water. Rinse with clean cool water. Air dry com- pletely before reinstalling.

5.Lightly oil air filter before installing to im- prove the efficiency of air filter. Use

6.Reinstall air filter.

7.Reinstall cylinder cover and 3 screws. TIghten securely.

Air Filter | Cylinder | |

Cover | ||

| ||

| Screws | |

| Cylinder | |

| Cover |

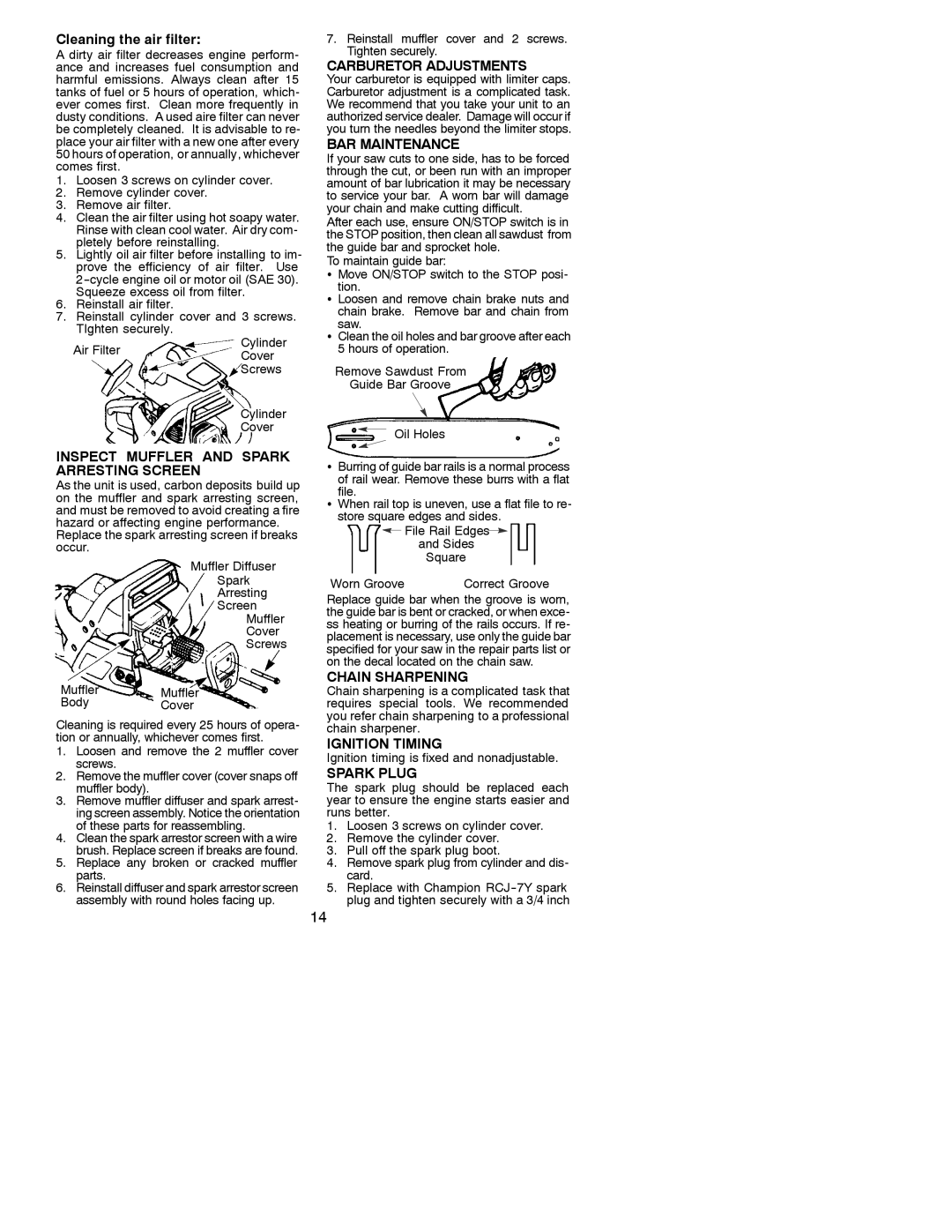

INSPECT MUFFLER AND SPARK ARRESTING SCREEN

As the unit is used, carbon deposits build up on the muffler and spark arresting screen, and must be removed to avoid creating a fire hazard or affecting engine performance.

Replace the spark arresting screen if breaks occur.

Muffler Diffuser

Spark Arresting Screen

Muffler

Cover

Screws

Muffler Muffler

BodyCover

Cleaning is required every 25 hours of opera- tion or annually, whichever comes first.

1.Loosen and remove the 2 muffler cover screws.

2.Remove the muffler cover (cover snaps off muffler body).

3.Remove muffler diffuser and spark arrest- ing screen assembly. Notice the orientation of these parts for reassembling.

4.Clean the spark arrestor screen with a wire brush. Replace screen if breaks are found.

5.Replace any broken or cracked muffler parts.

6.Reinstall diffuser and spark arrestor screen assembly with round holes facing up.

7.Reinstall muffler cover and 2 screws. Tighten securely.

CARBURETOR ADJUSTMENTS

Your carburetor is equipped with limiter caps. Carburetor adjustment is a complicated task. We recommend that you take your unit to an authorized service dealer. Damage will occur if you turn the needles beyond the limiter stops.

BAR MAINTENANCE

If your saw cuts to one side, has to be forced through the cut, or been run with an improper amount of bar lubrication it may be necessary to service your bar. A worn bar will damage your chain and make cutting difficult.

After each use, ensure ON/STOP switch is in the STOP position, then clean all sawdust from the guide bar and sprocket hole.

To maintain guide bar:

SMove ON/STOP switch to the STOP posi- tion.

SLoosen and remove chain brake nuts and chain brake. Remove bar and chain from

saw.

SClean the oil holes and bar groove after each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

SBurring of guide bar rails is a normal process of rail wear. Remove these burrs with a flat

file.

SWhen rail top is uneven, use a flat file to re- store square edges and sides.

![]() File Rail Edges

File Rail Edges![]()

and Sides

Square

Worn Groove | Correct Groove |

Replace guide bar when the groove is worn, the guide bar is bent or cracked, or when exce-

ssheating or burring of the rails occurs. If re- placement is necessary, use only the guide bar specified for your saw in the repair parts list or on the decal located on the chain saw.

CHAIN SHARPENING

Chain sharpening is a complicated task that requires special tools. We recommended you refer chain sharpening to a professional chain sharpener.

IGNITION TIMING

Ignition timing is fixed and nonadjustable.

SPARK PLUG

The spark plug should be replaced each year to ensure the engine starts easier and runs better.

1.Loosen 3 screws on cylinder cover.

2.Remove the cylinder cover.

3.Pull off the spark plug boot.

4.Remove spark plug from cylinder and dis- card.

5.Replace with Champion

14