PP446ET, 545177333 specifications

The Poulan 545177333 PP446ET is a cutting-edge chainsaw designed for both professional and home applications, offering efficiency and ease of use for a variety of cutting tasks. This model is particularly known for its robust design, powerful engine, and user-friendly features, making it a popular choice among landscapers, contractors, and DIY enthusiasts.One of the standout features of the PP446ET is its powerful 46cc two-stroke engine. This engine provides ample power for tackling tough jobs, from trimming trees to cutting firewood. The engine is designed with fuel efficiency in mind, ensuring that users can complete their tasks without frequent refueling interruptions. Additionally, the engine is engineered for reduced emissions, aligning with modern environmental standards and making it a more eco-friendly option.

The Poulan PP446ET is equipped with a 18-inch bar, allowing for greater reach and enhanced cutting capacity. This length is ideal for a wide range of tasks, from light pruning to larger limb removal and even felling small trees. The chainsaw features a low-profile chain, which aids in smoother cutting and reduces kickback, making it safer for inexperienced users.

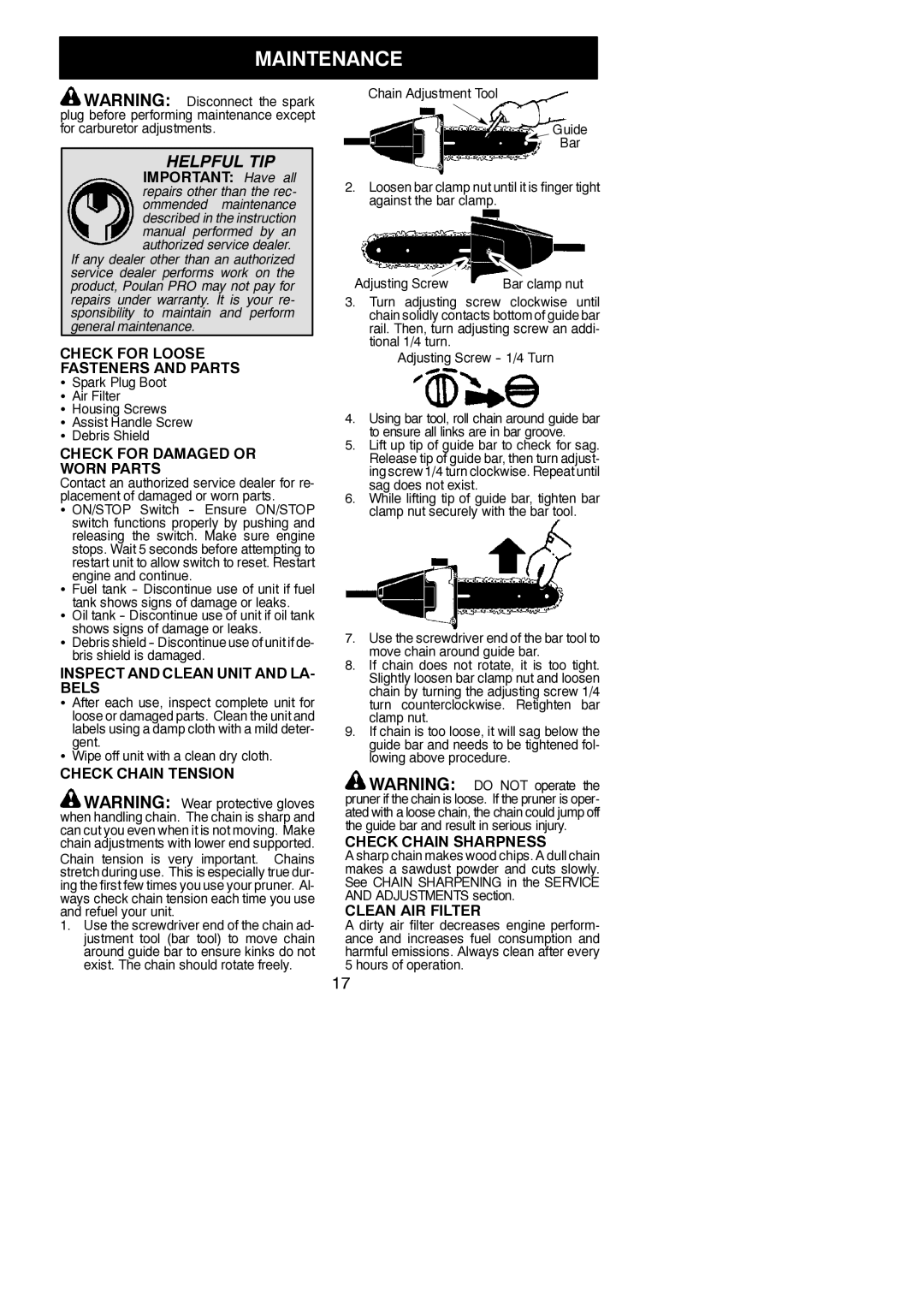

A key technological advancement in the PP446ET is its automatic oiling system. This system ensures consistent lubrication of the chain and bar, reducing wear and increasing the lifespan of the chainsaw. Moreover, the tool-free chain tensioning feature simplifies maintenance, allowing users to easily adjust the chain tension without the need for additional tools.

User comfort is also a priority in the design of the PP446ET. The chainsaw features an ergonomic handle, which provides a secure grip and reduces fatigue during prolonged usage. The anti-vibration technology incorporated into the design further enhances comfort, allowing users to work longer without discomfort.

Safety features are paramount in any chainsaw, and the PP446ET excels in this area. The chainsaw is equipped with a chain brake that stops the chain almost immediately in the event of a kickback, along with a safety throttle lock to prevent accidental starts.

Overall, the Poulan 545177333 PP446ET stands out as a reliable, powerful, and user-friendly chainsaw. Its combination of innovative technologies, user-centric design, and robust performance makes it an excellent choice for anyone looking to tackle their cutting tasks with efficiency and ease.