MAINTENANCE

CUSTOMER RESPONSIBILITIES

![]() WARNING: Disconnect power source before performing maintenance.

WARNING: Disconnect power source before performing maintenance.

Fill in dates as you complete | Before | After | Every | Service |

regular service | Use | Use | 15 min. | Dates |

Check for damaged/worn parts | n |

|

|

|

|

|

|

|

|

Check for loose fasteners/parts | n |

|

|

|

Check chain tension | n |

|

|

|

|

|

|

|

|

Check chain sharpness | n |

|

|

|

Check guide bar | n |

|

|

|

Check bar and chain oil level | n |

| n |

|

Inspect and clean unit & labels |

| n |

|

|

Clean guide bar groove |

| n |

|

|

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that have been subjected to oper- ator abuse or negligence. To receive full value from the warranty, the operator must maintain unit as instructed in this manual. Various adjustments will need to be made periodically to properly maintain your unit. Improper mainte- nance may cause damage to the unit and possible injury to the operator or by- standers.

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for replacement of worn or damaged parts. NOTE: It is normal for a small amount of oil to appear under the saw after motor stops. Do not confuse this with a leaking oil tank.

S Trigger Switch

SOil Tank

leaks.

S Extension Cord

CHECK FOR LOOSE FASTENERS AND PARTS

SBar Clamp Nuts S Chain

S Bar Adjusting Screw

12

CHECK CHAIN TENSION

![]() WARNING: Wear protective gloves when handling chain. The chain is sharp and can cut you even when it is not moving.

WARNING: Wear protective gloves when handling chain. The chain is sharp and can cut you even when it is not moving.

Chain tension is very important. Chain stretches during use. This is especially true during the first few times you use your saw. Always check chain tension each time you use your saw.

1.Unplug unit from the power source.

2.Use a screwdriver to move chain around guide bar to ensure kinks do not exist. The chain should rotate freely.

NOTE: It is recommended that the saw be turned upside down for chain tensioning.

3.Loosen bar clamp nuts until they are finger tight against the bar clamp.

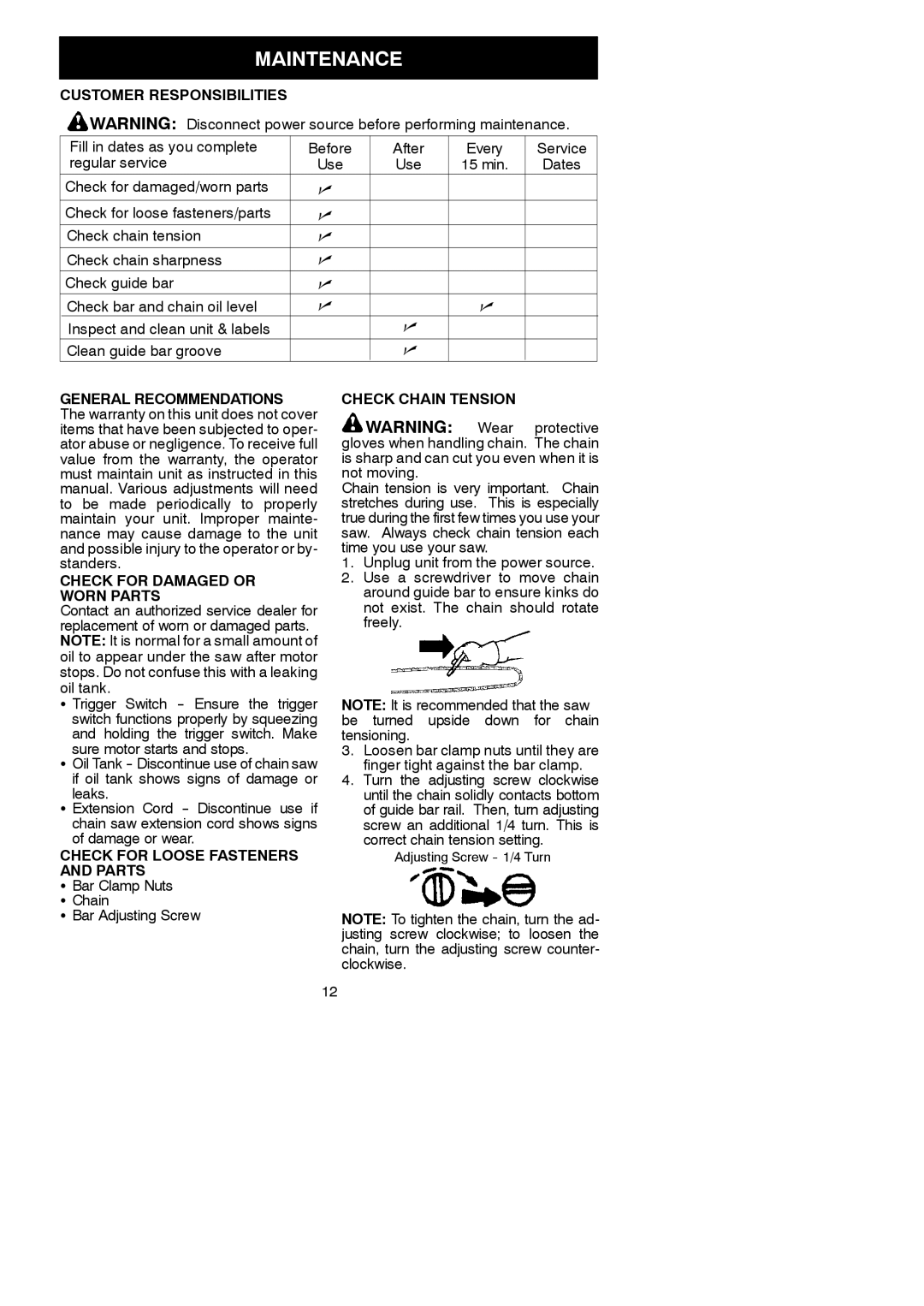

4.Turn the adjusting screw clockwise until the chain solidly contacts bottom of guide bar rail. Then, turn adjusting screw an additional 1/4 turn. This is correct chain tension setting.

Adjusting Screw

NOTE: To tighten the chain, turn the ad- justing screw clockwise; to loosen the chain, turn the adjusting screw counter- clockwise.