| OPERATION |

|

|

| |||

TRACTION DRIVE |

| BEFORE STARTING THE ENGINE |

| ||||

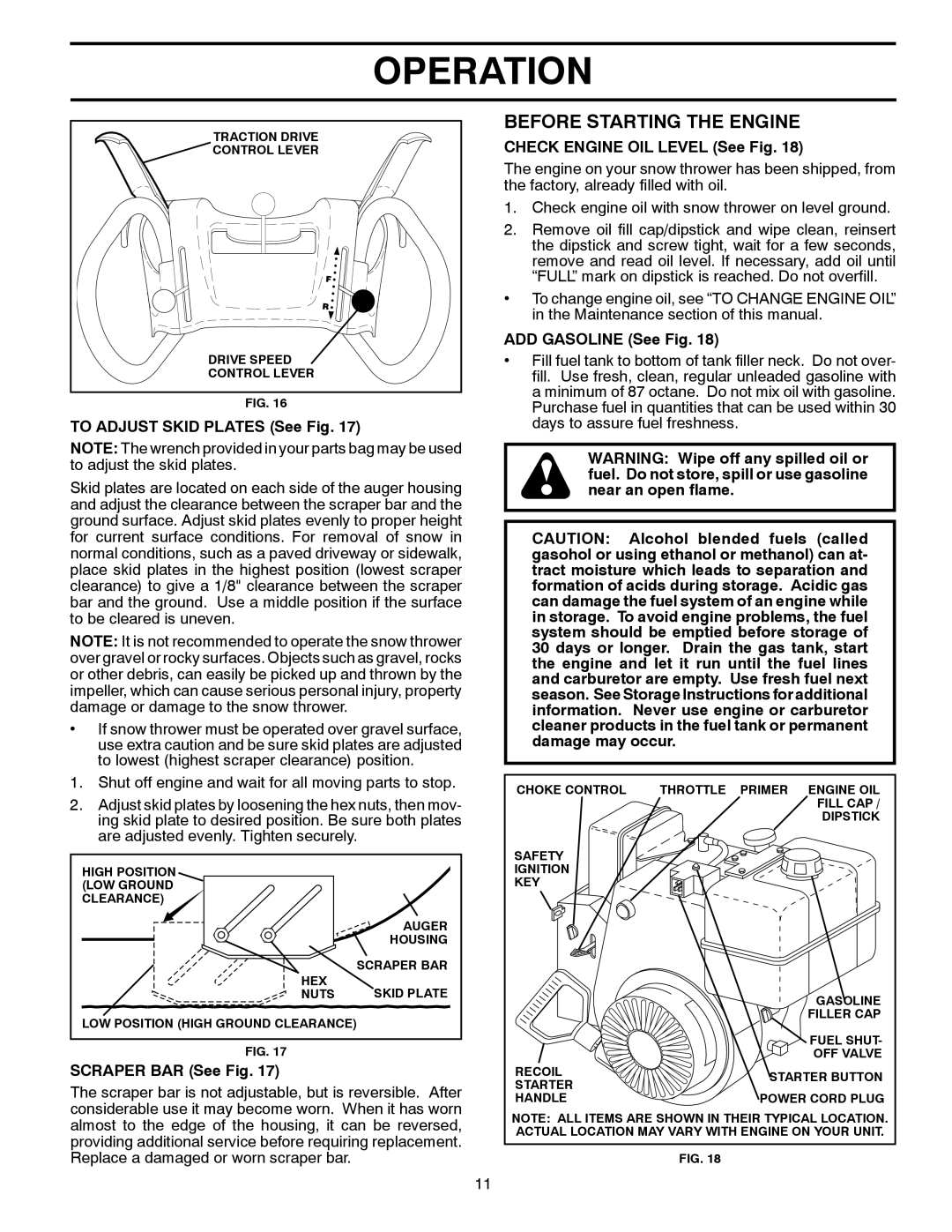

| CHECK ENGINE OIL LEVEL (See Fig. 18) |

| |||||

CONTROL LEVER |

|

| |||||

|

| The engine on your snow thrower has been shipped, from | |||||

|

| the factory, already filled with oil. |

|

| |||

|

| 1. | Check engine oil with snow thrower on level ground. | ||||

|

| 2. | Remove oil fill cap/dipstick and wipe clean, reinsert | ||||

|

|

| the dipstick and screw tight, wait for a few seconds, | ||||

|

|

| remove and read oil level. If necessary, add oil until | ||||

|

|

| “FULL” mark on dipstick is reached. Do not overfill. | ||||

|

| • | To change engine oil, see “TO CHANGE ENGINE OIL” | ||||

|

|

| in the Maintenance section of this manual. | ||||

|

| ADD GASOLINE (See Fig. 18) |

|

| |||

DRIVE SPEED |

| • | Fill fuel tank to bottom of tank filler neck. Do not over- | ||||

CONTROL LEVER |

|

| fill. Use fresh, clean, regular unleaded gasoline with | ||||

FIG. 16 |

|

| a minimum of 87 octane. Do not mix oil with gasoline. | ||||

|

| Purchase fuel in quantities that can be used within 30 | |||||

TO ADJUST SKID PLATES (See Fig. 17) |

|

| days to assure fuel freshness. |

|

| ||

NOTE: The wrench provided in your parts bag may be used |

| WARNING: Wipe off any spilled oil or | |||||

to adjust the skid plates. |

|

| |||||

|

| fuel. Do not store, spill or use gasoline | |||||

Skid plates are located on each side of the auger housing |

| ||||||

| near an open flame. |

|

| ||||

and adjust the clearance between the scraper bar and the |

|

|

|

|

| ||

ground surface. Adjust skid plates evenly to proper height |

|

|

|

|

| ||

for current surface conditions. For removal of snow in |

| CAUTION: | Alcohol blended fuels | (called | |||

normal conditions, such as a paved driveway or sidewalk, |

| gasohol or using ethanol or methanol) can at- | |||||

place skid plates in the highest position (lowest scraper |

| tract moisture which leads to separation and | |||||

clearance) to give a 1/8" clearance between the scraper |

| formation of acids during storage. Acidic gas | |||||

bar and the ground. Use a middle position if the surface |

| can damage the fuel system of an engine while | |||||

to be cleared is uneven. |

|

| in storage. To avoid engine problems, the fuel | ||||

NOTE: It is not recommended to operate the snow thrower |

| system should be emptied before storage of | |||||

| 30 days or longer. Drain the gas tank, start | ||||||

over gravel or rocky surfaces. Objects such as gravel, rocks |

| ||||||

| the engine and let it run until the fuel lines | ||||||

or other debris, can easily be picked up and thrown by the |

| ||||||

| and carburetor are empty. Use fresh fuel next | ||||||

impeller, which can cause serious personal injury, property |

| season. See Storage Instructions for additional | |||||

damage or damage to the snow thrower. |

|

| information. Never use engine or carburetor | ||||

• If snow thrower must be operated over gravel surface, |

| cleaner products in the fuel tank or permanent | |||||

use extra caution and be sure skid plates are adjusted |

| damage may occur. |

|

| |||

to lowest (highest scraper clearance) position. |

|

|

|

|

| ||

1. Shut off engine and wait for all moving parts to stop. | CHOKE CONTROL | THROTTLE | PRIMER | ENGINE OIL | |||

2. Adjust skid plates by loosening the hex nuts, then mov- | |||||||

|

|

|

| FILL CAP / | |||

ing skid plate to desired position. Be sure both plates |

|

|

|

| DIPSTICK | ||

are adjusted evenly. Tighten securely. |

|

|

|

|

|

| |

|

| SAFETY |

|

|

| ||

HIGH POSITION |

| IGNITION |

|

|

| ||

(LOW GROUND |

| KEY |

|

|

| ||

CLEARANCE) |

|

|

|

|

|

| |

| AUGER |

|

|

|

|

| |

| HOUSING |

|

|

|

|

| |

SCRAPER BAR |

|

|

|

|

| ||

HEX | SKID PLATE |

|

|

|

|

| |

NUTS |

|

|

|

| GASOLINE | ||

|

|

|

|

|

| ||

LOW POSITION (HIGH GROUND CLEARANCE) |

|

|

|

|

| FILLER CAP | |

|

|

|

|

|

| ||

FIG. 17 |

|

|

|

|

| FUEL SHUT- | |

|

|

|

|

| OFF VALVE | ||

SCRAPER BAR (See Fig. 17) | RECOIL |

| STARTER BUTTON | |

| ||||

The scraper bar is not adjustable, but is reversible. After | STARTER |

| ||

|

| |||

HANDLE |

| POWER CORD PLUG | ||

considerable use it may become worn. When it has worn |

| |||

NOTE: ALL ITEMS ARE SHOWN IN THEIR TYPICAL LOCATION. | ||||

almost to the edge of the housing, it can be reversed, | ||||

ACTUAL LOCATION MAY VARY WITH ENGINE ON YOUR UNIT. | ||||

providing additional service before requiring replacement. | ||||

|

|

| ||

|

|

| ||

Replace a damaged or worn scraper bar. |

|

| FIG. 18 | |

11