MAINTENANCE SCHEDULE

Check:

Fuel mixture level . . . . Before each use Bar lubrication . . . . . . . Before each use Chain tension . . . . . . . Before each use Chain sharpness . . . . . Before each use For damaged parts . . . Before each use For loose caps . . . . . . Before each use For loose fasteners . . . Before each use For loose parts . . . . . . Before each use

Inspect and Clean:

Bar . . . . . . . . . . . . . . . . Before each use Complete saw . . . . . . . After each use Air filter . . . . . . . . . . . . . Every 5 hours* Chain brake . . . . . . . . . Every 5 hours* Spark arresting screen

and muffler . . . . . . . . . . Every 25 hours* Replace spark plug . Yearly Replace fuel filter . . . Yearly

*Hours of Operation

Each hour of operation is approximately 2 tanks of fuel.

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that have been subjected to operator abuse or negligence. To receive full value from the war- ranty, the operator must maintain unit as in- structed in this manual. Various adjustments will need to be made periodically to properly maintain your unit.

SOnce a year, replace the spark plug, air filter, and check guide bar and chain for wear. A new spark plug and air filter assures proper

CHECK FOR DAMAGED OR WORN PARTS

Contact an authorized service dealer for re- placement of damaged or worn parts.

NOTE: It is normal for a small amount of oil to appear under the saw after engine stops. Do not confuse this with a leaking oil tank.

S ON/STOP Switch

S Fuel Tank

SOil Tank

CHECK FOR LOOSE

FASTENERS AND PARTS

SBar Nuts S Chain

S Muffler

S Cylinder Shield S Air Filter

S Handle Screws S Vibration Mounts S Starter Housing S Front Hand Guard

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull chain makes a sawdust powder and cuts slowly. See CHAIN SHARPENING.

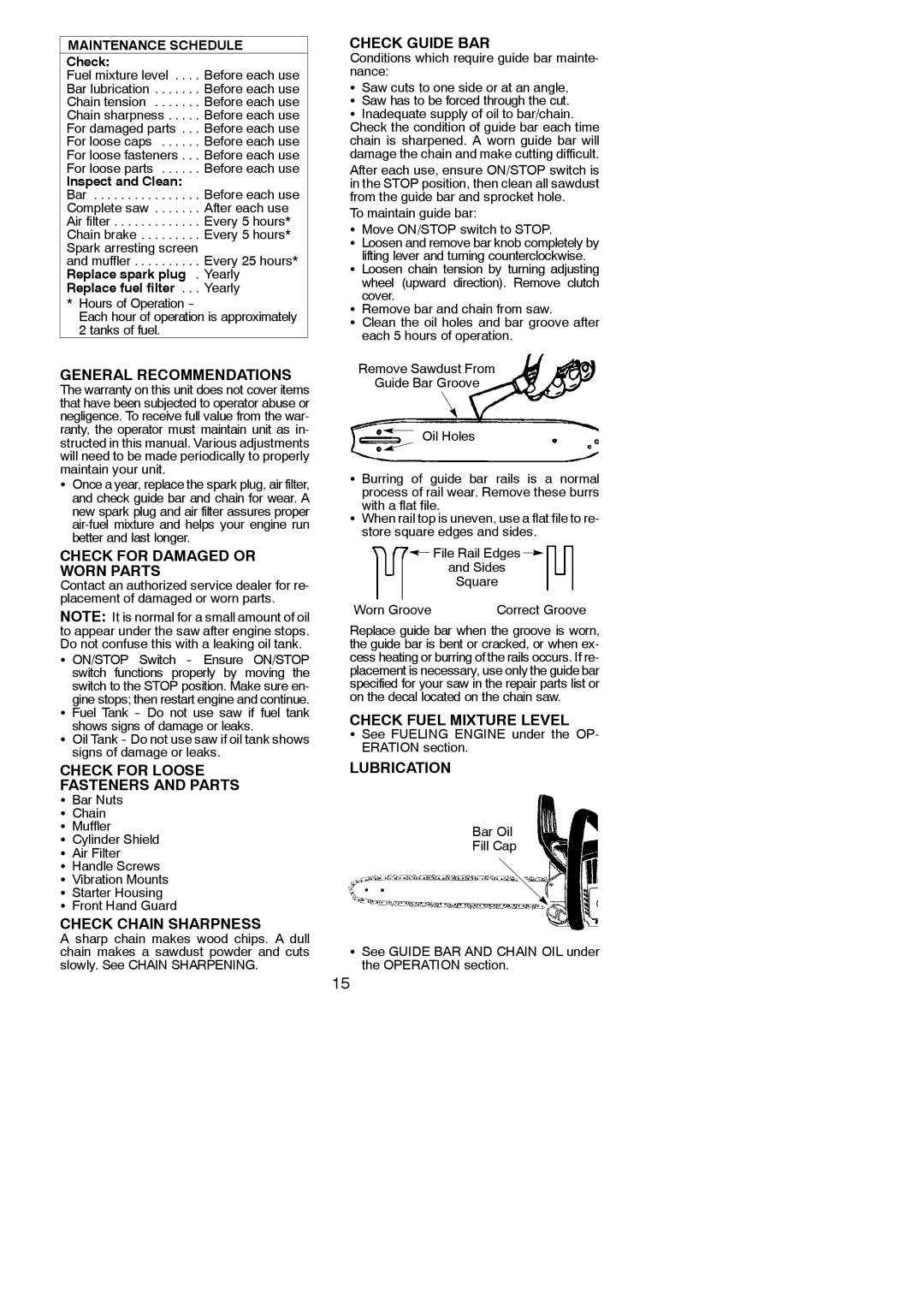

CHECK GUIDE BAR

Conditions which require guide bar mainte- nance:

SSaw cuts to one side or at an angle. S Saw has to be forced through the cut. S Inadequate supply of oil to bar/chain.

Check the condition of guide bar each time chain is sharpened. A worn guide bar will damage the chain and make cutting difficult.

After each use, ensure ON/STOP switch is in the STOP position, then clean all sawdust from the guide bar and sprocket hole.

To maintain guide bar:

SMove ON/STOP switch to STOP.

SLoosen and remove bar knob completely by

lifting lever and turning counterclockwise.

S Loosen chain tension by turning adjusting wheel (upward direction). Remove clutch cover.

SRemove bar and chain from saw.

SClean the oil holes and bar groove after each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal process of rail wear. Remove these burrs with a flat file.

SWhen rail top is uneven, use a flat file to re- store square edges and sides.

File Rail Edges ![]()

and Sides

Square

Worn Groove | Correct Groove |

Replace guide bar when the groove is worn, the guide bar is bent or cracked, or when ex- cess heating or burring of the rails occurs. If re- placement is necessary, use only the guide bar specified for your saw in the repair parts list or on the decal located on the chain saw.

CHECK FUEL MIXTURE LEVEL

S See FUELING ENGINE under the OP- ERATION section.

LUBRICATION

Bar Oil

Fill Cap

SSee GUIDE BAR AND CHAIN OIL under the OPERATION section.

15