CN1842STA specifications

The Poulan CN1842STA is a versatile and reliable riding lawn mower designed to make lawn care efficient and straightforward. With its robust features and reliable performance, this mower is ideal for homeowners with medium to large-sized lawns.One of the standout features of the Poulan CN1842STA is its powerful 18.5 HP Briggs & Stratton engine. This engine provides ample power for cutting through thick grass and tackling uneven terrain. The easy-starting engine ensures that users spend less time preparing and more time mowing.

The cutting deck of the CN1842STA is a 42-inch wide design, which allows for a larger cutting path while maintaining maneuverability around obstacles. The deck height can be easily adjusted to suit various grass lengths, providing flexibility in lawn care. With a cutting height range of 1 to 4 inches, users can customize their lawn treatment according to seasonal needs.

Another attractive aspect of this riding mower is its hydrostatic transmission. Unlike traditional gear-driven mowers, the hydrostatic transmission allows for smooth, effortless speed changes. This makes it easier to navigate tight spots or slow down for detailed trimming work.

The Poulan CN1842STA also features a comfortable high-back seat designed to reduce fatigue during long mowing sessions. The steering wheel is ergonomically designed, offering users excellent control and maneuverability. Moreover, the intuitive dashboard provides essential information at a glance, ensuring the operator can monitor performance without losing focus on the task.

Built with durability in mind, the CN1842STA features a rugged frame and strong chassis, designed to withstand the rigors of outdoor use. The mower's design incorporates a reinforced cutting deck, ensuring it can handle tough mowing conditions without compromising performance.

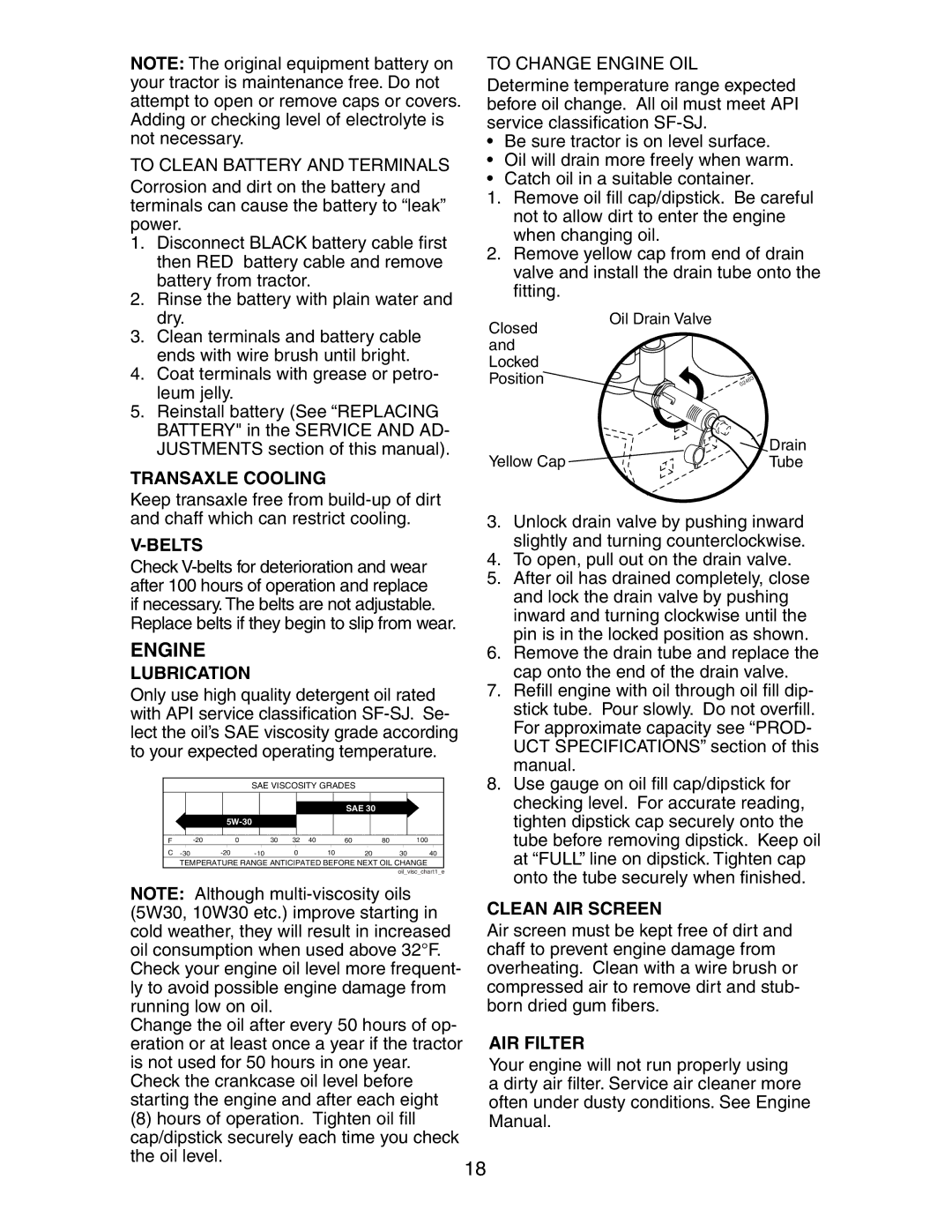

The Poulan CN1842STA is also equipped with ease of maintenance in mind. Access points for the engine and cutting deck are designed for convenience, allowing for quick oil changes and blade sharpening.

Overall, the Poulan CN1842STA offers an excellent blend of power, comfort, and reliability, making it a valuable asset for anyone looking to maintain a well-manicured lawn with minimal effort. With its combination of user-friendly features and robust technology, this riding mower stands out as a top choice for lawn care enthusiasts.