MAINTENANCE

CLEANING FUEL SEDIMENT CUP

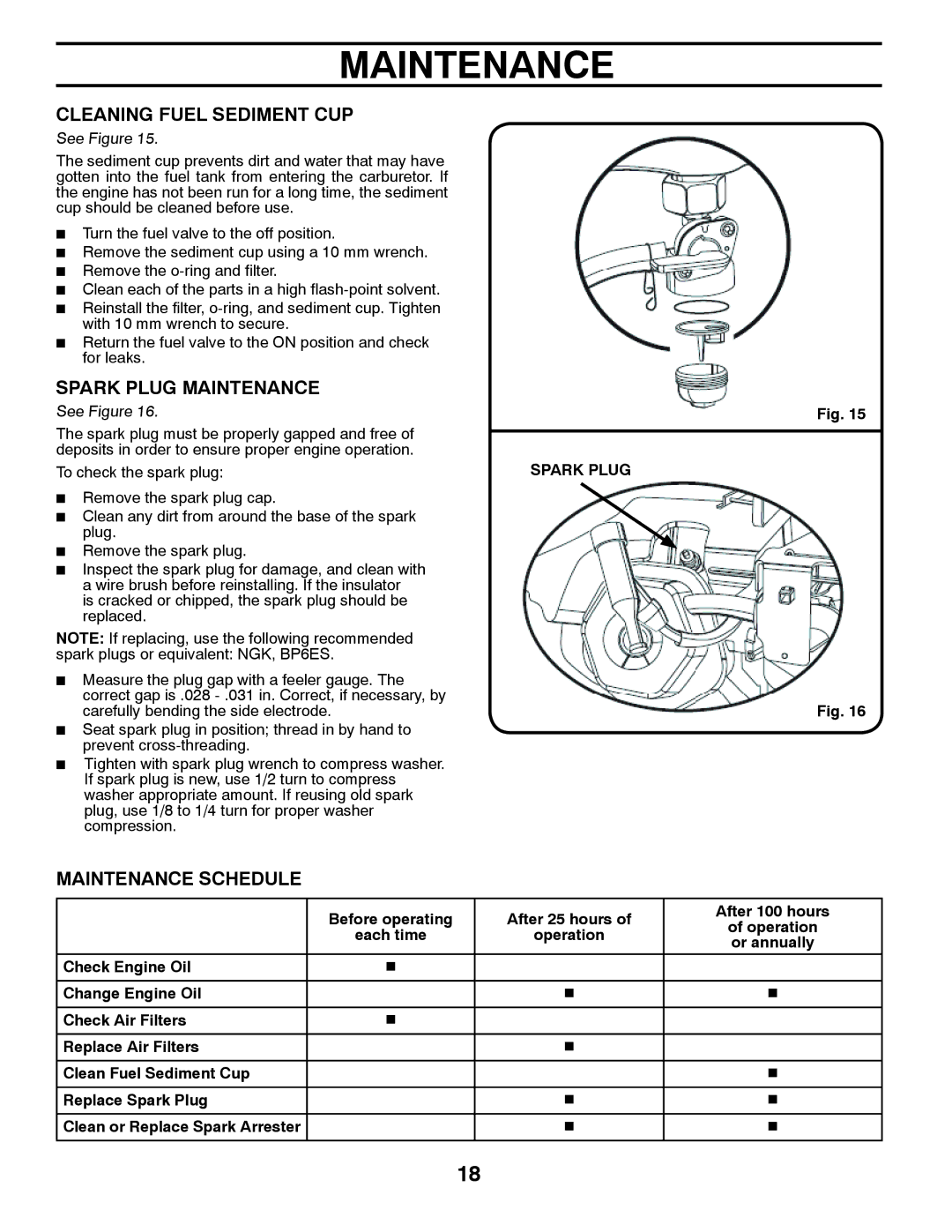

See Figure 15.

The sediment cup prevents dirt and water that may have gotten into the fuel tank from entering the carburetor. If the engine has not been run for a long time, the sediment cup should be cleaned before use.

■Turn the fuel valve to the off position.

■Remove the sediment cup using a 10 mm wrench.

■Remove the

■Clean each of the parts in a high

■Reinstall the filter,

■Return the fuel valve to the ON position and check for leaks.

SPARK PLUG MAINTENANCE

See Figure 16. | Fig. 15 |

The spark plug must be properly gapped and free of |

|

deposits in order to ensure proper engine operation. |

|

To check the spark plug: | SPARK PLUG |

■ Remove the spark plug cap. |

|

■ Clean any dirt from around the base of the spark |

|

plug. |

|

■ Remove the spark plug. |

|

■ Inspect the spark plug for damage, and clean with |

|

a wire brush before reinstalling. If the insulator |

|

is cracked or chipped, the spark plug should be |

|

replaced. |

|

NOTE: If replacing, use the following recommended |

|

spark plugs or equivalent: NGK, BP6ES. |

|

■Measure the plug gap with a feeler gauge. The correct gap is .028

carefully bending the side electrode. | Fig. 16 |

■Seat spark plug in position; thread in by hand to prevent

■Tighten with spark plug wrench to compress washer. If spark plug is new, use 1/2 turn to compress washer appropriate amount. If reusing old spark plug, use 1/8 to 1/4 turn for proper washer compression.

MAINTENANCE SCHEDULE

| Before operating | After 25 hours of | After 100 hours |

| of operation | ||

| each time | operation | |

| or annually | ||

|

|

| |

Check Engine Oil | ■ |

|

|

|

|

|

|

Change Engine Oil |

| ■ | ■ |

|

|

|

|

Check Air Filters | ■ |

|

|

|

|

|

|

Replace Air Filters |

| ■ |

|

|

|

|

|

Clean Fuel Sediment Cup |

|

| ■ |

|

|

|

|

Replace Spark Plug |

| ■ | ■ |

|

|

|

|

Clean or Replace Spark Arrester |

| ■ | ■ |

|

|

|

|

18