dusty conditions. A used aire filter can never be completely cleaned. It is advisable to re- place your air filter with a new one after every 50 hours of operation, or annually, whichever comes first.

1.Loosen 3 screws on cylinder cover.

2.Remove cylinder cover.

3.Remove air filter.

4.Clean the air filter using hot soapy water. Rinse with clean cool water. Air dry com- pletely before reinstalling.

5.Lightly oil air filter before installing to im- prove the efficiency of air filter. Use

6.Reinstall air filter.

7.Reinstall cylinder cover and 3 screws. TIghten securely.

|

|

|

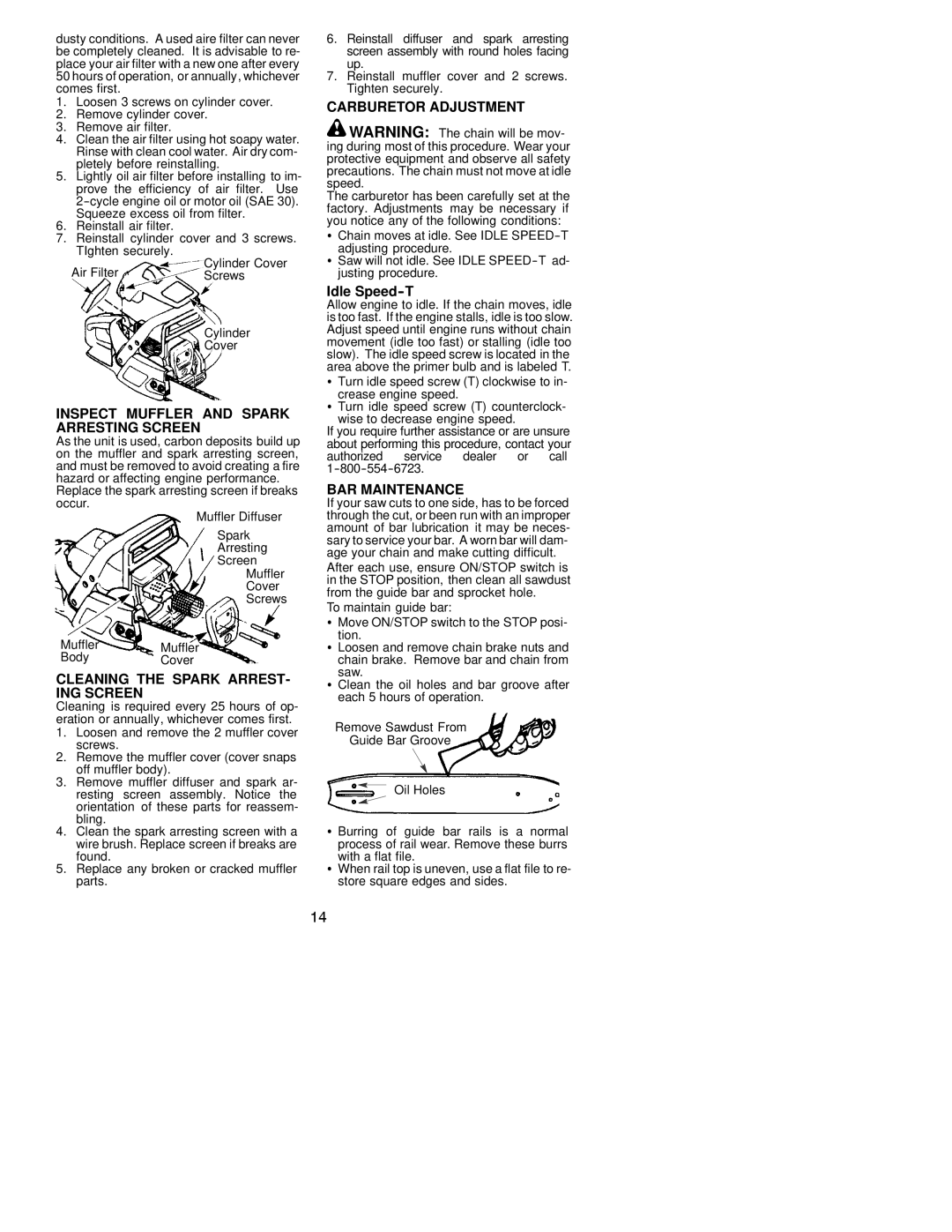

Air Filter | Cylinder Cover | |

Screws | ||

|

|

|

| Cylinder | |

| Cover |

|

INSPECT MUFFLER AND SPARK ARRESTING SCREEN

As the unit is used, carbon deposits build up on the muffler and spark arresting screen, and must be removed to avoid creating a fire hazard or affecting engine performance.

Replace the spark arresting screen if breaks occur.

Muffler Diffuser

Spark Arresting Screen

Muffler

Cover

Screws

Muffler Muffler

BodyCover

CLEANING THE SPARK ARREST- ING SCREEN

Cleaning is required every 25 hours of op- eration or annually, whichever comes first.

1.Loosen and remove the 2 muffler cover screws.

2.Remove the muffler cover (cover snaps off muffler body).

3.Remove muffler diffuser and spark ar- resting screen assembly. Notice the orientation of these parts for reassem- bling.

4.Clean the spark arresting screen with a wire brush. Replace screen if breaks are found.

5.Replace any broken or cracked muffler parts.

6.Reinstall diffuser and spark arresting screen assembly with round holes facing up.

7.Reinstall muffler cover and 2 screws. Tighten securely.

CARBURETOR ADJUSTMENT

![]() WARNING: The chain will be mov- ing during most of this procedure. Wear your protective equipment and observe all safety precautions. The chain must not move at idle speed.

WARNING: The chain will be mov- ing during most of this procedure. Wear your protective equipment and observe all safety precautions. The chain must not move at idle speed.

The carburetor has been carefully set at the factory. Adjustments may be necessary if you notice any of the following conditions:

SChain moves at idle. See IDLE

adjusting procedure.

SSaw will not idle. See IDLE

Idle Speed-T

Allow engine to idle. If the chain moves, idle is too fast. If the engine stalls, idle is too slow. Adjust speed until engine runs without chain movement (idle too fast) or stalling (idle too slow). The idle speed screw is located in the area above the primer bulb and is labeled T.

STurn idle speed screw (T) clockwise to in-

crease engine speed.

STurn idle speed screw (T) counterclock- wise to decrease engine speed.

If you require further assistance or are unsure about performing this procedure, contact your authorized service dealer or call

BAR MAINTENANCE

If your saw cuts to one side, has to be forced through the cut, or been run with an improper amount of bar lubrication it may be neces- sary to service your bar. A worn bar will dam- age your chain and make cutting difficult.

After each use, ensure ON/STOP switch is in the STOP position, then clean all sawdust from the guide bar and sprocket hole.

To maintain guide bar:

SMove ON/STOP switch to the STOP posi-

tion.

SLoosen and remove chain brake nuts and chain brake. Remove bar and chain from saw.

S Clean the oil holes and bar groove after each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal process of rail wear. Remove these burrs with a flat file.

SWhen rail top is uneven, use a flat file to re- store square edges and sides.

14