7.The Edge Sander should be located in a dry,

8.Exposed metal areas of the Edge Sander have been factory coated with a protectant. This should be removed with a soft cloth dampened with kerosene or mineral spirits. Do not use an abrasive pad. Do not let solvent contact plastic or rubber parts as it may damage them.

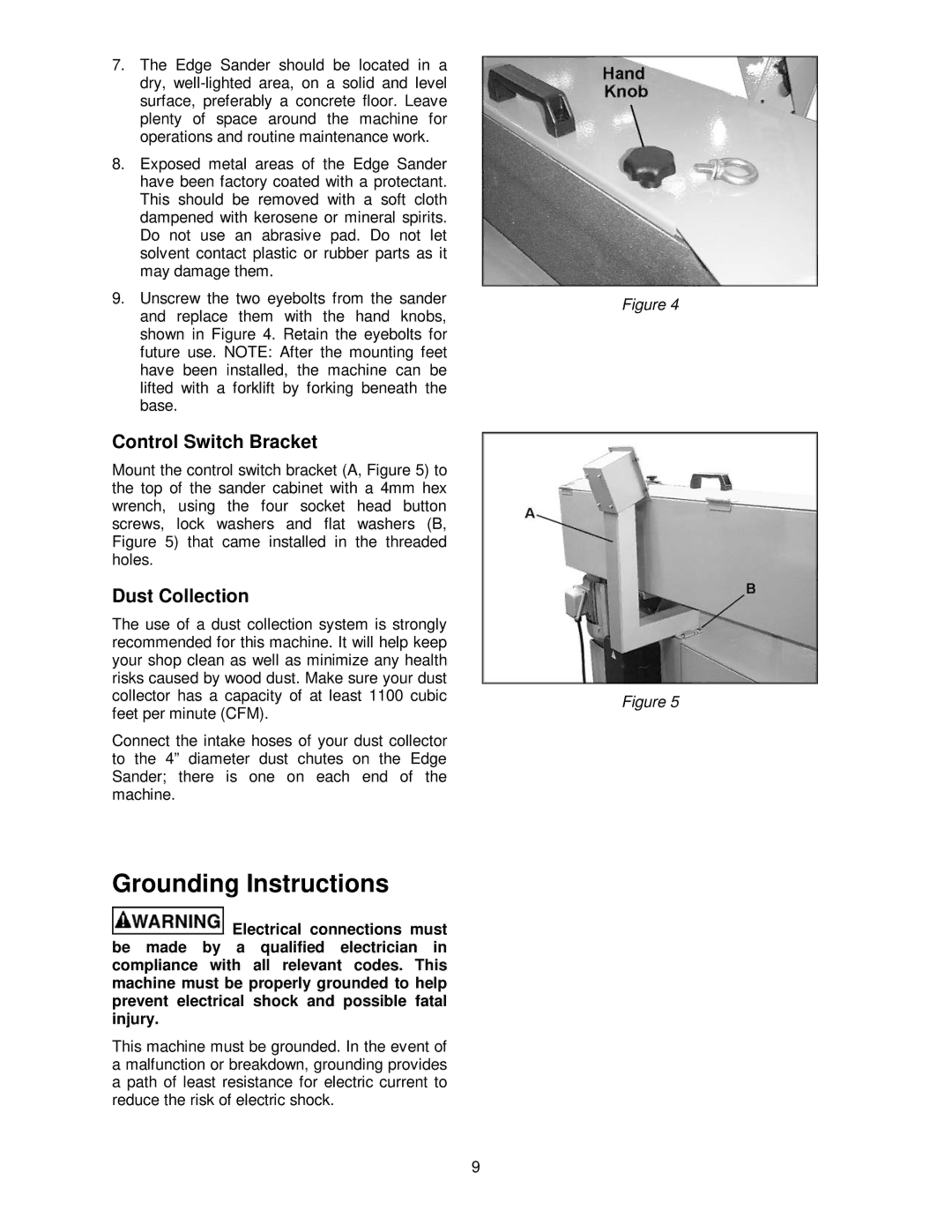

9.Unscrew the two eyebolts from the sander and replace them with the hand knobs, shown in Figure 4. Retain the eyebolts for future use. NOTE: After the mounting feet have been installed, the machine can be lifted with a forklift by forking beneath the base.

Control Switch Bracket

Mount the control switch bracket (A, Figure 5) to the top of the sander cabinet with a 4mm hex wrench, using the four socket head button screws, lock washers and flat washers (B, Figure 5) that came installed in the threaded holes.

Dust Collection

The use of a dust collection system is strongly recommended for this machine. It will help keep your shop clean as well as minimize any health risks caused by wood dust. Make sure your dust collector has a capacity of at least 1100 cubic feet per minute (CFM).

Connect the intake hoses of your dust collector to the 4” diameter dust chutes on the Edge Sander; there is one on each end of the machine.

Grounding Instructions

![]() Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury.

Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury.

This machine must be grounded. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

Figure 4

Figure 5

9