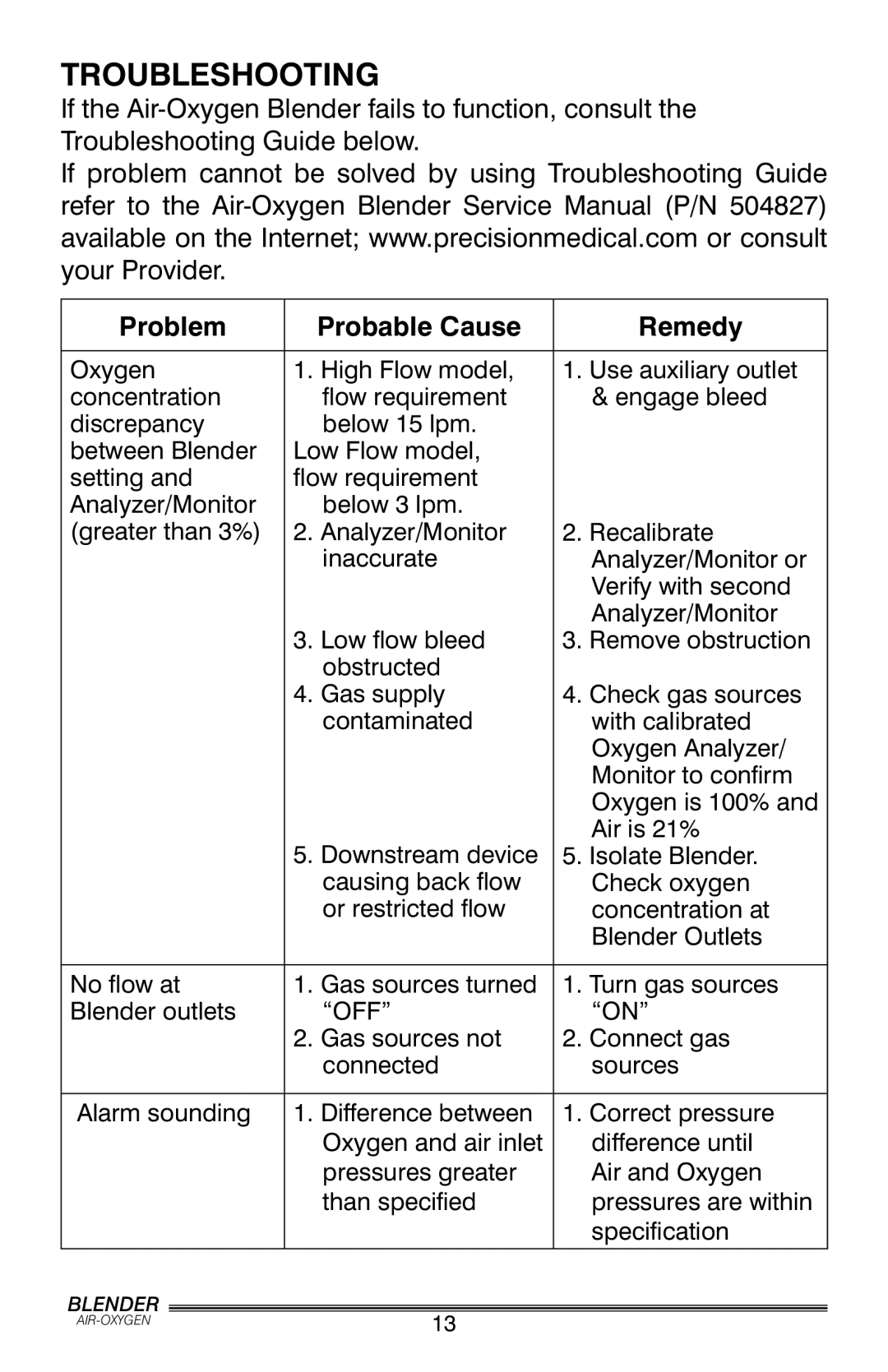

Troubleshooting

If the

If problem cannot be solved by using Troubleshooting Guide refer to the

Problem |

| Probable Cause |

| Remedy |

|

|

|

|

|

Oxygen | 1. | High Flow model, | 1. | Use auxiliary outlet |

concentration |

| flow requirement |

| & engage bleed |

discrepancy |

| below 15 lpm. |

|

|

between Blender | Low Flow model, |

|

| |

setting and | flow requirement |

|

| |

Analyzer/Monitor |

| below 3 lpm. |

|

|

(greater than 3%) | 2. | Analyzer/Monitor | 2. | Recalibrate |

|

| inaccurate |

| Analyzer/Monitor or |

|

|

|

| Verify with second |

|

|

|

| Analyzer/Monitor |

| 3. | Low flow bleed | 3. | Remove obstruction |

|

| obstructed |

|

|

| 4. | Gas supply | 4. | Check gas sources |

|

| contaminated |

| with calibrated |

|

|

|

| Oxygen Analyzer/ |

|

|

|

| Monitor to confirm |

|

|

|

| Oxygen is 100% and |

| 5. | Downstream device |

| Air is 21% |

| 5. | Isolate Blender. | ||

|

| causing back flow |

| Check oxygen |

|

| or restricted flow |

| concentration at |

|

|

|

| Blender Outlets |

|

|

|

|

|

No flow at | 1. | Gas sources turned | 1. | Turn gas sources |

Blender outlets |

| “OFF” |

| “ON” |

| 2. | Gas sources not | 2. | Connect gas |

|

| connected |

| sources |

|

|

|

|

|

Alarm sounding | 1. | Difference between | 1. | Correct pressure |

|

| Oxygen and air inlet |

| difference until |

|

| pressures greater |

| Air and Oxygen |

|

| than specified |

| pressures are within |

|

|

|

| specification |

Blender |

|

| |

| |

13 | |

|