NESHAP 319

2 and 3 Stage Compliant System

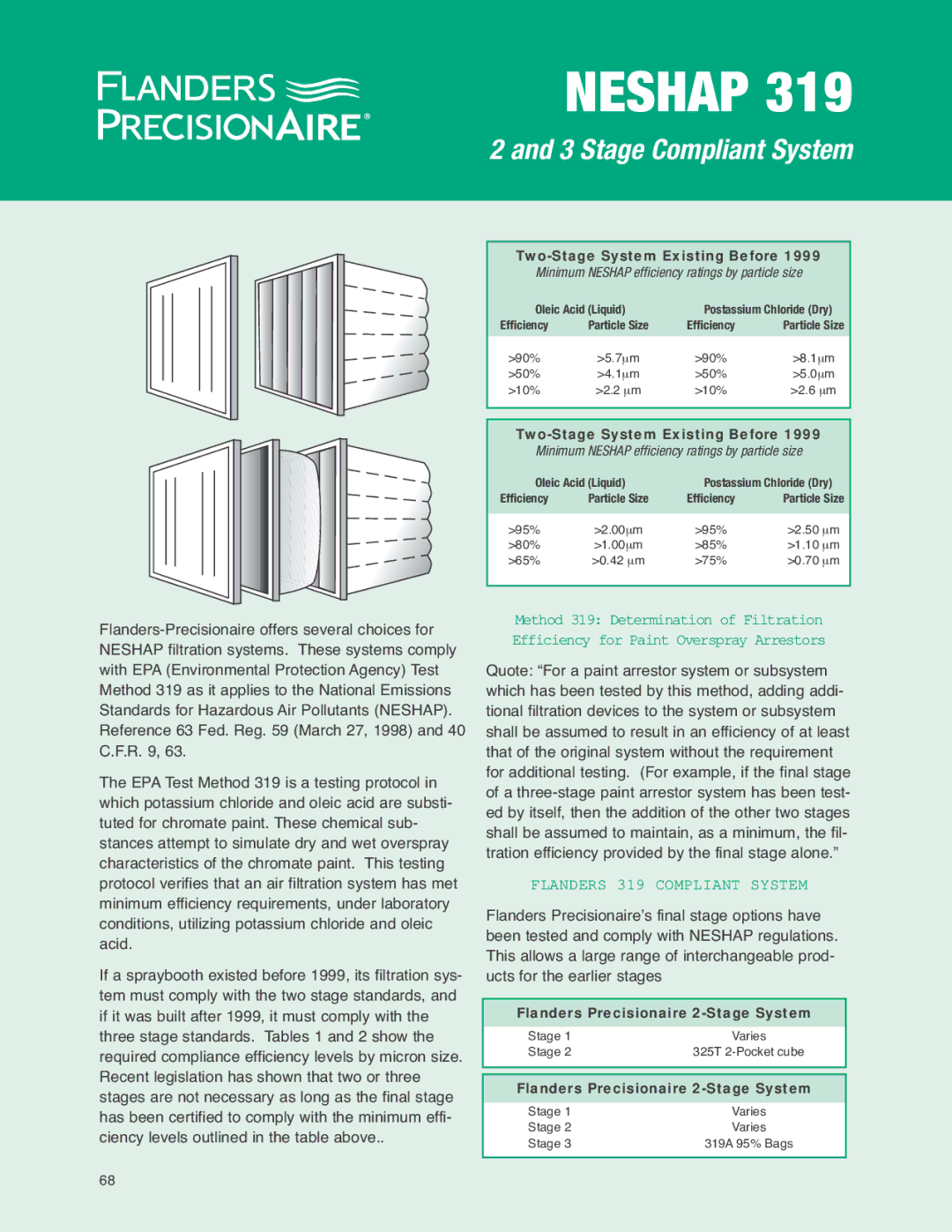

Two-Stage System Existing Before 1999

Minimum NESHAP efficiency ratings by particle size

Oleic Acid (Liquid) | Postassium Chloride (Dry) | ||

Efficiency | Particle Size | Efficiency | Particle Size |

>90% | >5.7∝m | >90% | >8.1∝m |

>50% | >4.1∝m | >50% | >5.0∝m |

>10% | >2.2 ∝m | >10% | >2.6 ∝m |

Minimum NESHAP efficiency ratings by particle size

Oleic Acid (Liquid) | Postassium Chloride (Dry) | ||

Efficiency | Particle Size | Efficiency | Particle Size |

>95% | >2.00∝m | >95% | >2.50 ∝m |

>80% | >1.00∝m | >85% | >1.10 ∝m |

>65% | >0.42 ∝m | >75% | >0.70 ∝m |

The EPA Test Method 319 is a testing protocol in which potassium chloride and oleic acid are substi- tuted for chromate paint. These chemical sub- stances attempt to simulate dry and wet overspray characteristics of the chromate paint. This testing protocol verifies that an air filtration system has met minimum efficiency requirements, under laboratory conditions, utilizing potassium chloride and oleic acid.

If a spraybooth existed before 1999, its filtration sys- tem must comply with the two stage standards, and if it was built after 1999, it must comply with the three stage standards. Tables 1 and 2 show the required compliance efficiency levels by micron size. Recent legislation has shown that two or three stages are not necessary as long as the final stage has been certified to comply with the minimum effi- ciency levels outlined in the table above..

Method 319: Determination of Filtration Efficiency for Paint Overspray Arrestors

Quote: “For a paint arrestor system or subsystem which has been tested by this method, adding addi- tional filtration devices to the system or subsystem shall be assumed to result in an efficiency of at least that of the original system without the requirement for additional testing. (For example, if the final stage of a

FLANDERS 319 COMPLIANT SYSTEM

Flanders Precisionaire’s final stage options have been tested and comply with NESHAP regulations. This allows a large range of interchangeable prod- ucts for the earlier stages

Flanders Precisionaire

Stage 1 | Varies |

Stage 2 | 325T |

Flanders Precisionaire

Stage 1 | Varies |

Stage 2 | Varies |

Stage 3 | 319A 95% Bags |

68