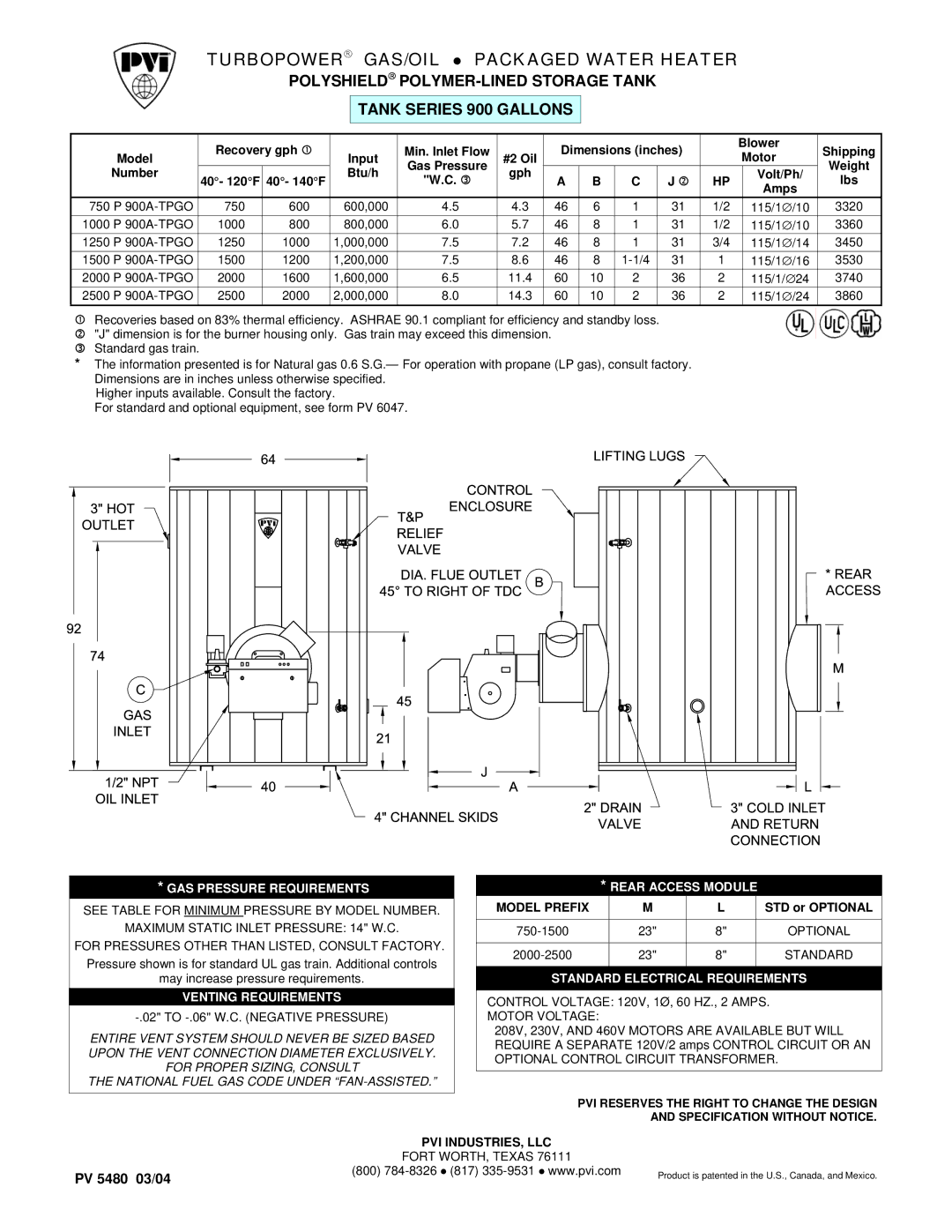

1000P900A-TPGO, 1500P900A-TPGO, Tank Series, 2000P900A-TPGO, 1250P900A-TPGO specifications

PVI Industries has garnered a reputation for delivering premium quality tank solutions that cater to various industrial needs. Among its distinguished offerings is the PVI Industries Tank Series, which exemplifies the perfect blend of durability, efficiency, and advanced technology. This series of tanks is designed to meet the demanding requirements of many industries, including oil, gas, chemicals, and water treatment.One of the standout features of the PVI Tank Series is its construction quality. The tanks are manufactured using high-grade materials that are resistant to corrosion and wear, thereby ensuring longevity and minimal maintenance. The tanks are often designed in accordance with industry standards, which means they are rigorously tested for performance and safety before being deployed. The series showcases various tank designs, including vertical, horizontal, and specialized configurations, each tailored to specific operational requirements.

In terms of technological advancement, the PVI Tank Series incorporates innovative solutions such as advanced insulation systems to optimize thermal performance. This is particularly beneficial for industries dealing with temperature-sensitive materials. The tanks come equipped with leading-edge monitoring systems that enable real-time tracking of levels, pressure, and temperature. These smart features facilitate proactive maintenance and operational efficiency, significantly reducing the risk of failures or leaks.

Additionally, the PVI Tank Series emphasizes user-friendly design, with features that ensure easy access for inspection and maintenance. Manways, access hatches, and fitting placements are strategically positioned to streamline these processes. Moreover, the tanks can be customized with various ports and fittings, allowing for easy integration into existing systems and processes.

Another important characteristic of the PVI Tank Series is its commitment to environmental sustainability. The tanks are designed with eco-friendly practices in mind, minimizing their environmental footprint while maximizing performance. The incorporation of secondary containment options and leak detection technology helps ensure compliance with environmental regulations and protects against spills.

Overall, the PVI Industries Tank Series stands out for its robust design, state-of-the-art technologies, and user-centric features. Whether for storing hazardous materials or managing waste, these tanks offer reliability and safety that industries can depend on. With ongoing commitment to innovation and quality, PVI Industries continues to set the standard in tank solutions, meeting the dynamic needs of today's industrial landscape.