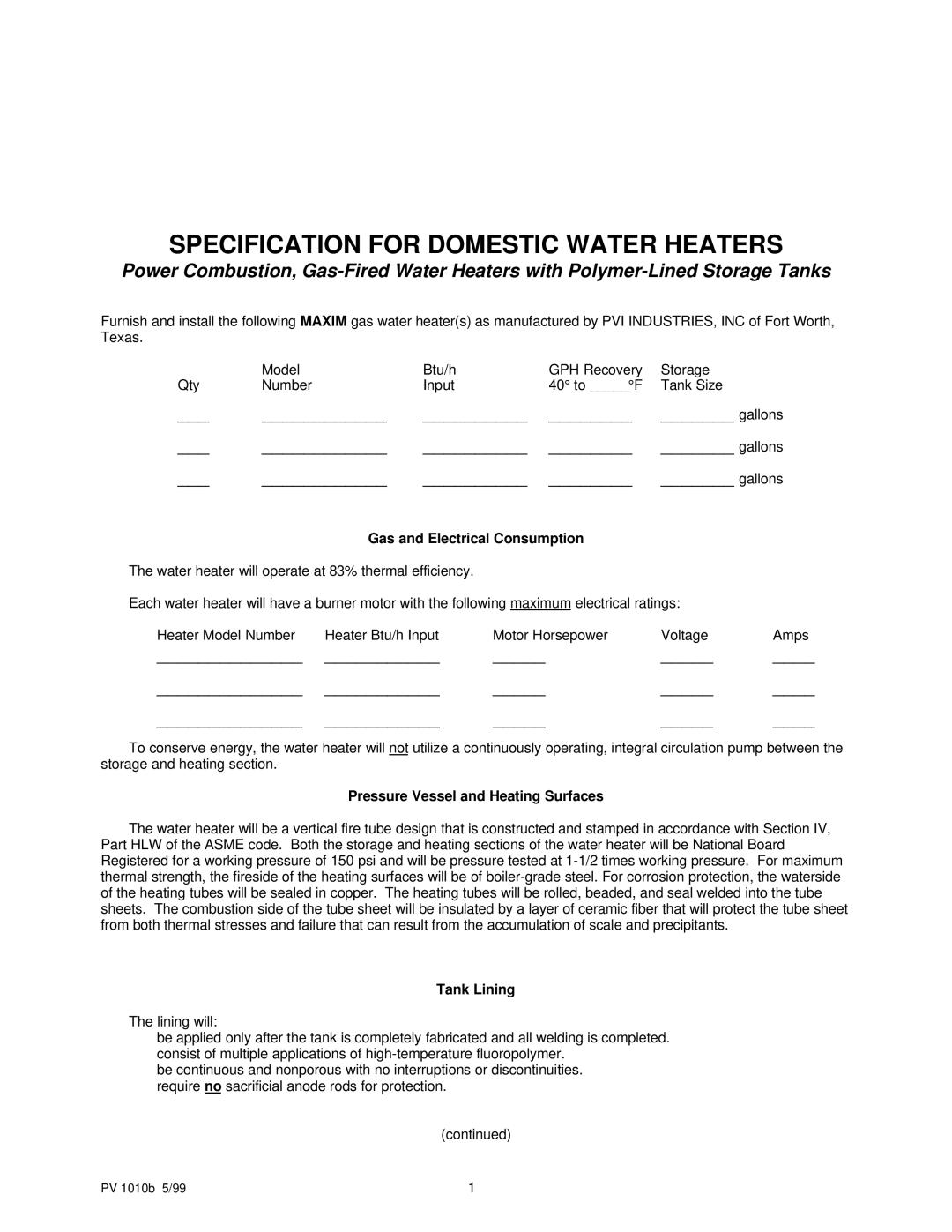

PV 1010b specifications

PVI Industries has made a significant impact in the industrial sector with its innovative products, and one of its standout offerings is the PV 1010B. This model exemplifies the company’s dedication to enhancing performance through advanced engineering and cutting-edge technologies.The PV 1010B is a versatile industrial pump designed to meet a variety of operational requirements. One of its main features is its robust construction, which ensures durability and longevity even in challenging environments. The materials used in the casing and internal components are resistant to corrosion, making the PV 1010B suitable for handling a wide range of fluids, including aggressive chemicals.

A key technological advancement in the PV 1010B is its high-efficiency motor. The pump is equipped with a premium-grade motor that not only delivers powerful performance but also operates quietly and consumes less energy. This makes it an environmentally friendly option while helping reduce operational costs for businesses.

The PV 1010B also incorporates a user-friendly control system that allows for easy operation and maintenance. Digitally integrated controls provide real-time monitoring of the pump's performance, enabling operators to quickly identify any issues and address them proactively. This feature significantly enhances reliability, ensuring that the unit can operate continuously with minimal downtime.

Moreover, the PV 1010B is designed with safety as a priority. It features built-in thermal overload protection that safeguards the motor from overheating, preventing potential failures and extending the lifespan of the equipment. The pump also has various installation configurations, allowing it to be adapted to different setups and applications.

Efficiency is another hallmark of the PV 1010B. The pump's hydraulic design maximizes flow rates while minimizing energy consumption. This efficiency not only translates into cost savings but also supports sustainability initiatives by reducing the carbon footprint of operations.

In summary, the PVI Industries PV 1010B is a robust, efficient, and technologically advanced industrial pump. Its combination of durable construction, high-efficiency motor, user-friendly controls, and safety features make it an ideal choice for industries requiring reliable fluid handling solutions. With the PV 1010B, PVI Industries continues to demonstrate its commitment to delivering exceptional products that meet the evolving needs of the market.