SELECTING AN ABRASIVE BELT

The principle abrasive materials used on belts for machine sanding are aluminum oxide and silicon carbide. Aluminum oxide is the softer of the two, but is tougher and more suited for woods and soft

Abrasives are classed as

To obtain the best finish, start with a “COARSE” grade of abrasive and change to “MEDIUM” and then to“FINE” as work progresses.

GENERAL SANDING

SECURE THE WORK and maintain a FIRM GRIP on the sander. Friction between the sanding belt and the work will tend to move the work backward and the sander forward.

ALWAYS be sure that the switch is OFF before connecting the tool to the power source.

1.Hold the sander off the work before starting the motor.

2.Lower the sander to the work, touching the rear part of the belt first. Level the machine when moving it forward.

3.Guide the machine over the work in overlapping strokes. Allow the sander to do the work.

4.Avoid applying excessive pressure. The weight of the machine is usually sufficient for a fast smooth finish. A slight increase in pressure may speed removal of material, but too much pressure will slow the motor and decrease removal.

5.Work back and forth over a fairly wide area to obtain an even surface.

6.Do not let the tool tilt. The edge of the belt can make a deep cuts into the surface.

7.Do not pause in any one spot during the sanding operation. The belt will eat into the work and make the surface uneven.

8.Lift the tool from the work before turning the motor off.

9.Always be sure that the motor has completely stopped before putting the tool down.

FAST SANDING ON ROUGH WORK

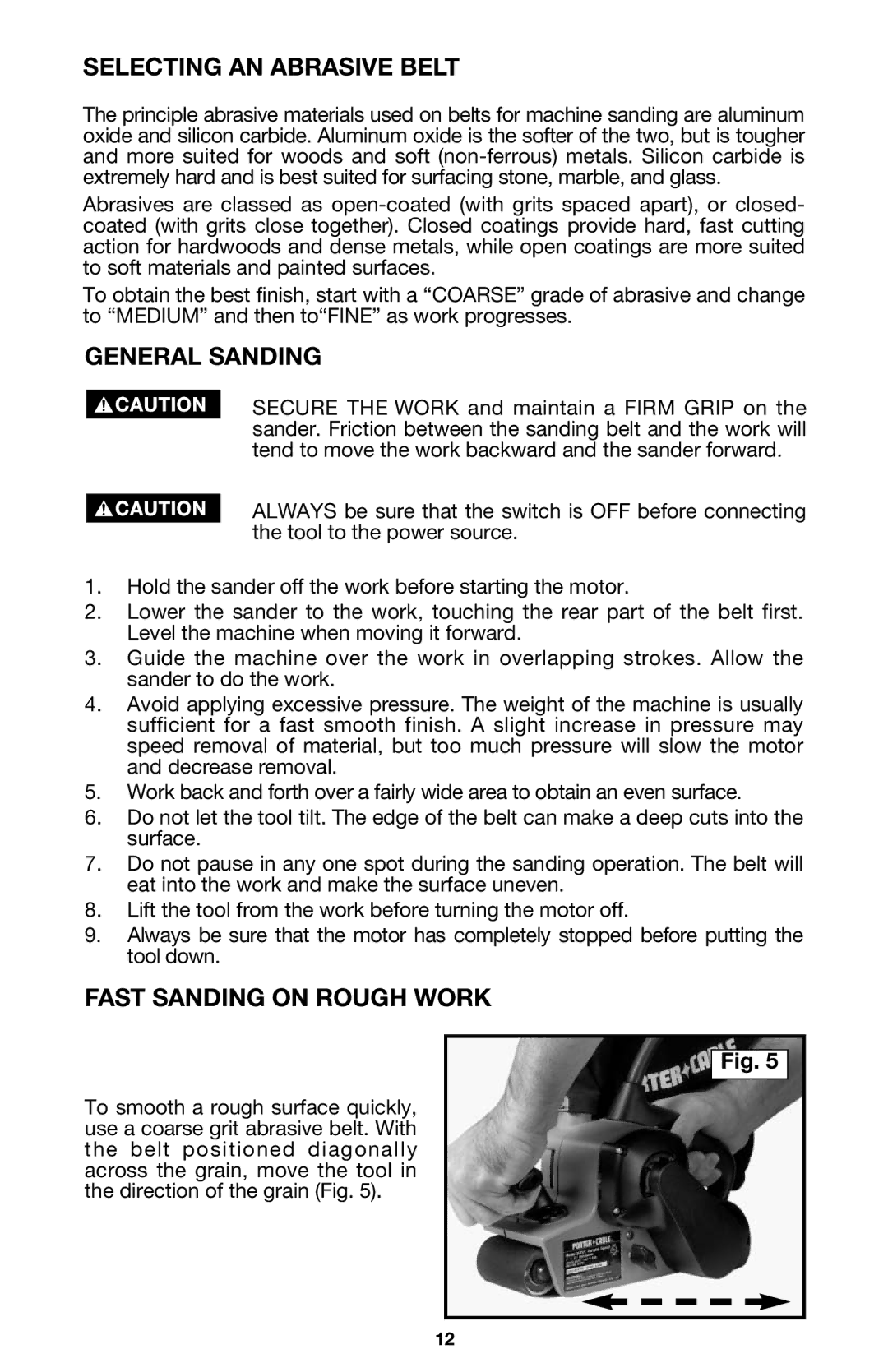

To smooth a rough surface quickly, use a coarse grit abrasive belt. With the belt positioned diagonally across the grain, move the tool in the direction of the grain (Fig. 5).

Fig. 5

12