3. Operation

F9

F10

F11

F12

hands.

•A reacting motion may occur on the auger when spinning drill has hit on stones or tree roots under the ground. Always hold the auger securely to control such motion.

•Start drilling with

•When the drill has been caught in the ground and cannot be pulled out, stop the engine and rotate the auger

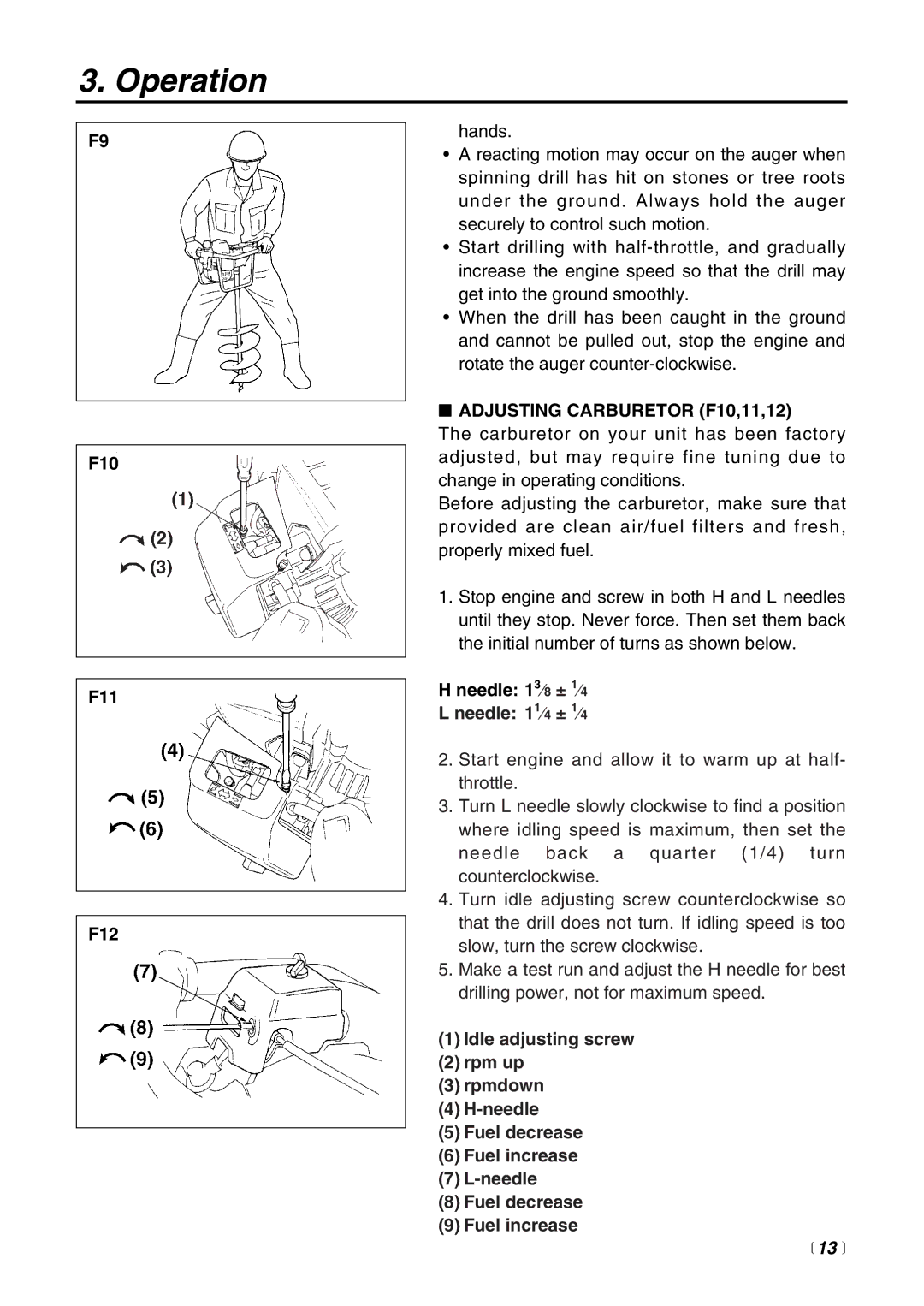

■ADJUSTING CARBURETOR (F10,11,12)

The carburetor on your unit has been factory adjusted, but may require fine tuning due to change in operating conditions.

Before adjusting the carburetor, make sure that provided are clean air/fuel filters and fresh, properly mixed fuel.

1.Stop engine and screw in both H and L needles until they stop. Never force. Then set them back the initial number of turns as shown below.

Hneedle: 13⁄8 ± 1⁄4 L needle: 11⁄4 ± 1⁄4

2.Start engine and allow it to warm up at half- throttle.

3.Turn L needle slowly clockwise to find a position where idling speed is maximum, then set the needle back a quarter (1/4) turn counterclockwise.

4.Turn idle adjusting screw counterclockwise so that the drill does not turn. If idling speed is too slow, turn the screw clockwise.

5.Make a test run and adjust the H needle for best drilling power, not for maximum speed.

(1)Idle adjusting screw

(2)rpm up

(3)rpmdown

(4)

(5)Fuel decrease

(6)Fuel increase

(7)

(8)Fuel decrease

(9)Fuel increase

13