anode rod inspection

CAUTION

Property Damage Hazard

•Avoid water heater damage.

•Inspection and replacement of anode rod required.

The anode rod is used to protect the tank from corrosion. Most hot water tanks are equipped with an anode rod. The submerged rod sacrifices itself to protect the tank. Instead of corroding tank, water ions attack and eat away the anode rod. This does not affect water’s taste or color. The rod must be maintained to keep tank in operating condition.

Anode deterioration depends on water conductivity, not necessarily water condition. A corroded or pitted anode rod indicates high water conductivity and should be checked and/or replaced more often than an anode rod that appears to be intact. Replacement of a depleted anode rod can extend the life of your water heater. Inspection should be conducted by a qualified technician, and at a minimum should be checked annually after the warranty period.

Artificially softened water is exceedingly corrosive because the process substitutes sodium ions for magnesium and calcium ions.

The use of a water softener may decrease the life of the water heater tank.

The anode rod should be removed from the water heater tank every 3 years for inspection. NOTE: artificially softened water requires the anode rod to be inspected annually.

Draining and flushing

Burn harzard.

Burn harzard.

Hot water discharge.

Hot water discharge.

Keep hands clear of drain valve discharge.

Keep hands clear of drain valve discharge.

It is recommended that the water heater storage tank be drained and flushed every 6 months to reduce sediment buildup. The water heater should be drained if being shut down during freezing temperatures. See Features And Components in this manual for the location of the water heater components described below.

TO DRAIN THE WATER HEATER STORAGE TANK:

1.Turn off the electrical supply to the water heater.

2.Turn off the gas supply at the Main Gas Shutoff Valve if the water heater is going to be shut down for an extended period.

3.Ensure the cold water inlet valve is open.

4.Open a nearby hot water faucet and let the water run until the water is no longer hot.

5.Close the cold water inlet valve to the water heater.

6.Connect a hose to the water heater drain valve and terminate it to an adequate drain.

7.Open the water heater drain valve and allow all the water to drain from the storage tank.

8.Close the water heater drain valve when all water in the storage tank has drained.

9.Close the hot water faucet opened in Step 4.

10.If the water heater is going to be shut down for an extended period, the drain valve should be left open.

TO FLUSH THE WATER HEATER STORAGE TANK:

1.Turn off the electrical supply to the water heater.

2.Ensure the cold water inlet valve is open.

3.Open a nearby hot water faucet and let the water run until

the water is no longer hot. Then close the hot water faucet.

4.Connect a hose to the drain valve and terminate it to an adequate drain.

5.Ensure the drain hose is secured before and during the entire flushing procedure. Flushing is performed with system water pressure applied to the water heater.

6.Open the water heater drain valve to flush the storage tank.

7.Flush the water heater storage tank to remove sediment and allow the water to flow until it runs clean.

8.Close the water heater drain valve when flushing is completed.

9.Remove the drain hose.

10.Fill the water heater - see Filling The Water Heater in this manual.

11.Turn on the electrical supply to place the water heater back in operation.

12.Allow the water heater to complete several heating cycles to ensure it is operating properly.

recommended procedure for periodic removal of lime deposits from tank type commercial water heaters

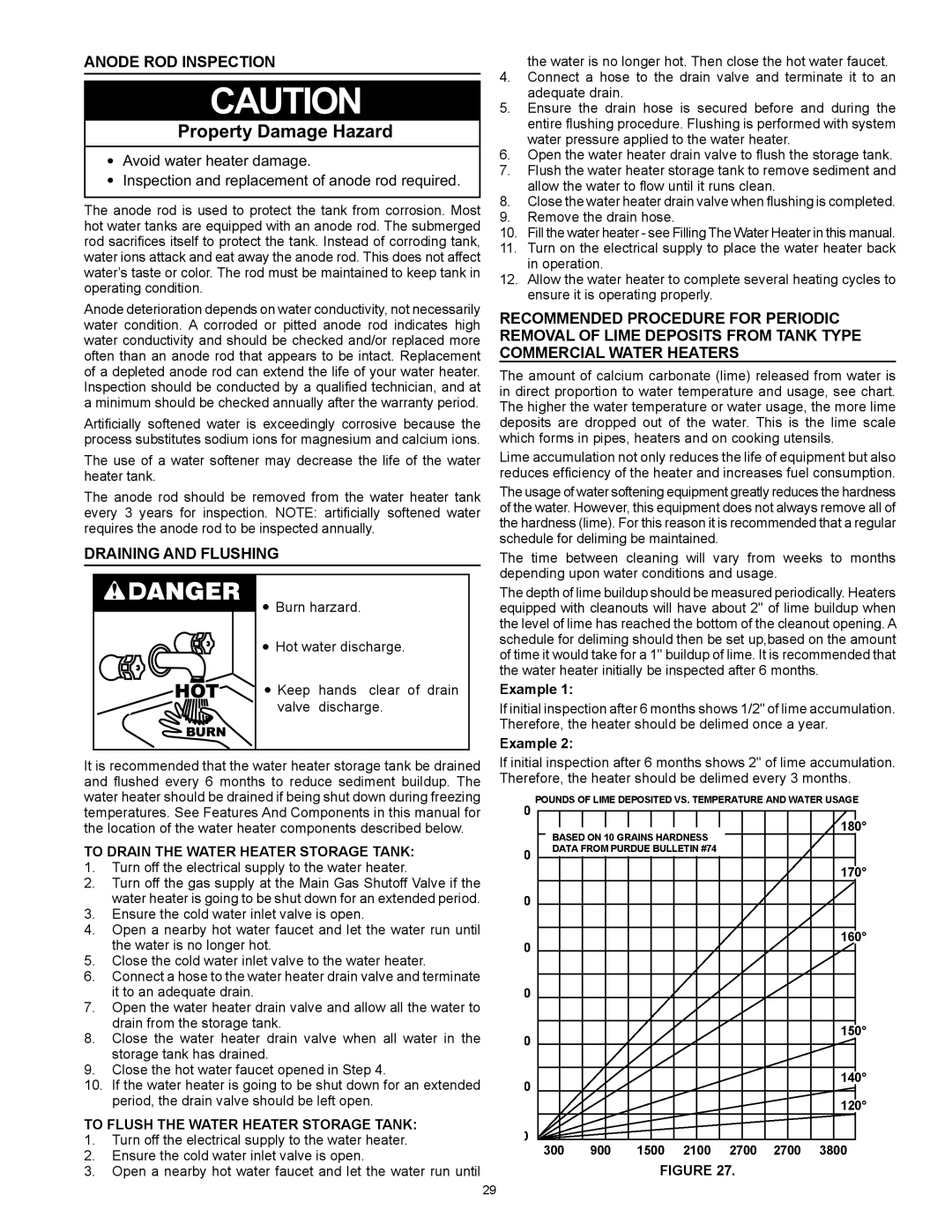

The amount of calcium carbonate (lime) released from water is in direct proportion to water temperature and usage, see chart. The higher the water temperature or water usage, the more lime deposits are dropped out of the water. This is the lime scale which forms in pipes, heaters and on cooking utensils.

Lime accumulation not only reduces the life of equipment but also reduces efficiency of the heater and increases fuel consumption.

The usage of water softening equipment greatly reduces the hardness of the water. However, this equipment does not always remove all of the hardness (lime). For this reason it is recommended that a regular schedule for deliming be maintained.

The time between cleaning will vary from weeks to months depending upon water conditions and usage.

The depth of lime buildup should be measured periodically. Heaters equipped with cleanouts will have about 2" of lime buildup when the level of lime has reached the bottom of the cleanout opening. A schedule for deliming should then be set up,based on the amount of time it would take for a 1" buildup of lime. It is recommended that the water heater initially be inspected after 6 months.

Example 1:

If initial inspection after 6 months shows 1/2" of lime accumulation. Therefore, the heater should be delimed once a year.

Example 2:

If initial inspection after 6 months shows 2" of lime accumulation. Therefore, the heater should be delimed every 3 months.

FIGURE 27.