WHY PUMP TANKS ARE IMPORTANT

A pump tank is an essential part of any well system, delivering these benefits:

nIt ensures that your pump will run for at least one minute each time it cycles, as required by pump manufacturers.

nIt stores a supplemental water supply between pump cycles, to reduce the number of cycles throughout the day, and helps prolong pump life.

nIt helps maintain water pressure within your system, ensuring proper operation of your dishwasher and washing machine, and robust flow for showering and bathing.

A properly sized pump and pump tank will work as a team to meet your needs and will deliver many years of dependable service.

HOW TO INSTALL A PUMP TANK

Each

1.Determining proper tank location.

2.Attaching the acceptance fittings.

3.Adjusting the tank

4.Leveling the tank and connecting it to the water supply line.

5.

TOOLS NEEDED FOR INSTALLATION

n | Screwdriver | n | Pipe Wrench | n | Hacksaw |

n | Pliers | n | Teflon Tape | n | Pressure Gauge |

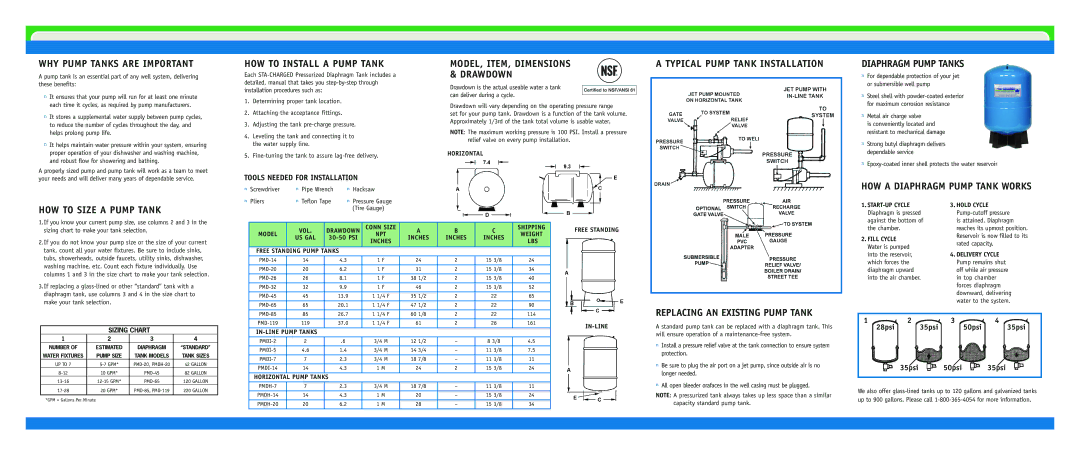

MODEL, ITEM, DIMENSIONS & DRAWDOWN

Drawdown is the actual useable water a tank can deliver during a cycle.

Drawdown will vary depending on the operating pressure range

set for your pump tank. Drawdown is a function of the tank volume. Approximately 1/3rd of the tank total volume is usable water.

NOTE: The maximum working pressure is 100 PSI. Install a pressure relief valve on every pump installation.

HORIZONTAL

A TYPICAL PUMP TANK INSTALLATION

DIAPHRAGM PUMP TANKS

nFor dependable protection of your jet or submersible well pump

nSteel shell with

nMetal air charge valve

is conveniently located and resistant to mechanical damage

nStrong butyl diaphragm delivers dependable service

n

HOW A DIAPHRAGM PUMP TANK WORKS

HOW TO SIZE A PUMP TANK

(Tire Gauge) |

1. |

Diaphragm is pressed |

3. HOLD CYCLE |

1.If you know your current pump size, use columns 2 and 3 in the sizing chart to make your tank selection.

2.If you do not know your pump size or the size of your current tank, count all your water fixtures. Be sure to include sinks, tubs, showerheads, outside faucets, utility sinks, dishwasher, washing machine, etc. Count each fixture individually. Use columns 1 and 3 in the size chart to make your tank selection.

3.If replacing a

MODEL | VOL. | DRAWDOWN | CONN SIZE | A | B | C | SHIPPING |

US GAL | NPT | INCHES | INCHES | INCHES | WEIGHT | ||

| INCHES | LBS | |||||

|

|

|

|

|

| ||

FREE STANDING PUMP TANKS |

|

|

|

|

| ||

14 | 4.3 | 1 F | 24 | 2 | 15 3/8 | 24 | |

|

|

|

|

|

|

|

|

20 | 6.2 | 1 F | 31 | 2 | 15 3/8 | 34 | |

|

|

|

|

|

|

|

|

26 | 8.1 | 1 F | 38 1/2 | 2 | 15 3/8 | 40 | |

|

|

|

|

|

|

|

|

32 | 9.9 | 1 F | 46 | 2 | 15 3/8 | 52 | |

|

|

|

|

|

|

|

|

45 | 13.9 | 1 1/4 F | 35 1/2 | 2 | 22 | 65 | |

|

|

|

|

|

|

|

|

65 | 20.1 | 1 1/4 F | 47 1/2 | 2 | 22 | 90 | |

|

|

|

|

|

|

|

|

85 | 26.7 | 1 1/4 F | 60 1/8 | 2 | 22 | 114 | |

FREE STANDING

REPLACING AN EXISTING PUMP TANK

against the bottom of |

the chamber. |

2. FILL CYCLE |

Water is pumped |

into the reservoir, |

which forces the |

diaphragm upward |

into the air chamber. |

is attained. Diaphragm |

reaches its upmost position. |

Reservoir is now filled to its |

rated capacity. |

4. DELIVERY CYCLE |

Pump remains shut |

off while air pressure |

in top chamber |

forces diaphragm |

downward, delivering |

water to the system. |

SIZING CHART

1 |

| 2 | 3 | 4 |

NUMBER OF |

| ESTIMATED | DIAPHRAGM | “STANDARD” |

WATER FIXTURES |

| PUMP SIZE | TANK MODELS | TANK SIZES |

UP TO 7 |

| 42 GALLON | ||

| 10 GPM* | 82 GALLON | ||

| 120 GALLON | |||

| 20 GPM* | 220 GALLON | ||

|

|

|

|

|

*GPM = Gallons Per Minute |

|

|

| |

119 |

| 37.0 | 1 1/4 F | 61 | 2 | 26 | 161 | |

|

|

|

|

|

|

| ||

2 |

| .6 | 3/4 M | 12 1/2 | – | 8 3/8 | 4.5 | |

|

|

|

|

|

|

|

|

|

4.6 |

| 1.4 | 3/4 M | 14 3/4 | – | 11 3/8 | 7.5 | |

|

|

|

|

|

|

|

|

|

7 |

| 2.3 | 3/4 M | 18 7/8 | – | 11 3/8 | 11 | |

|

|

|

|

|

|

|

|

|

14 |

| 4.3 | 1 M | 24 | 2 | 15 3/8 | 24 | |

|

|

|

|

|

|

|

|

|

HORIZONTAL | PUMP TANKS |

|

|

|

|

|

|

|

7 |

| 2.3 | 3/4 M | 18 7/8 | – | 11 3/8 | 11 | |

|

|

|

|

|

|

|

|

|

14 |

| 4.3 | 1 M | 20 | – | 15 3/8 | 24 | |

|

|

|

|

|

|

|

|

|

20 |

| 6.2 | 1 M | 28 | – | 15 3/8 | 34 | |

|

|

|

|

|

|

|

|

|

IN-LINE

A standard pump tank can be replaced with a diaphragm tank. This will ensure operation of a

nInstall a pressure relief valve at the tank connection to ensure system protection.

nBe sure to plug the air port on a jet pump, since outside air is no longer needed.

nAll open bleeder orafaces in the well casing must be plugged.

NOTE: A pressurized tank always takes up less space than a similar capacity standard pump tank.

1 | 2 | 35psi | 3 | 4 |

| 28psi | 50psi | 35psi |

35psi 50psi 35psi

We also offer