Maintenance (Continued)

!WARNING

Filter Removal, Inspection and Replacement

To change a filter, pull off the filter housing cover. If filter element is dirty, replace ele- ment or entire filter.

Safety valve must be replaced if it cannot be actuated or it leaks air after ring is released.

3.Daily with compressor shut off: Depressurize system prior to draining tank. Drain moisture from tank by opening the tank drain valve under- neath the tank.

4.Turn power OFF and clean dust and dirt from motor, tank, air lines and pump cooling fins.

NOTE: The air filter in the filter housing on the side of the head must be checked and cleaned periodically, more often if used under very dusty conditions or when a great deal of fog from spraying is allowed to circulate near unit.

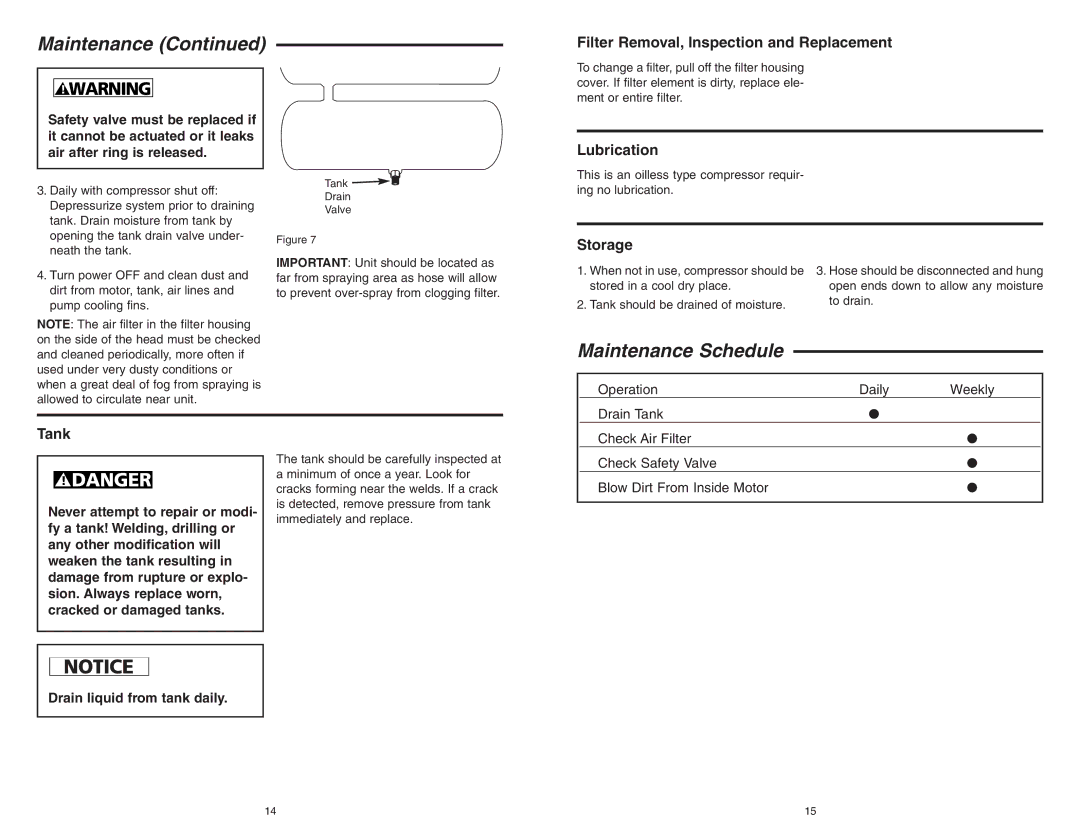

Tank ![]()

![]()

![]()

Drain

Valve

Figure 7

IMPORTANT: Unit should be located as far from spraying area as hose will allow to prevent

Lubrication

This is an oilless type compressor requir- ing no lubrication.

Storage

1. When not in use, compressor should be | 3. Hose should be disconnected and hung |

stored in a cool dry place. | open ends down to allow any moisture |

2. Tank should be drained of moisture. | to drain. |

|

Maintenance Schedule

Operation | Daily | Weekly |

Drain Tank | ● |

|

Tank

!DANGER

Never attempt to repair or modi- fy a tank! Welding, drilling or any other modification will weaken the tank resulting in damage from rupture or explo- sion. Always replace worn, cracked or damaged tanks.

The tank should be carefully inspected at a minimum of once a year. Look for cracks forming near the welds. If a crack is detected, remove pressure from tank immediately and replace.

|

|

Check Air Filter | ● |

Check Safety Valve | ● |

Blow Dirt From Inside Motor | ● |

NOTICE

Drain liquid from tank daily.

14 | 15 |