OPERATION

DRY-FIRE LOCKOUT

When the magazine is almost empty of nails, the

To resume operation, reload the tool with nails.

SETTING THE AIR PRESSURE

The amount of air pressure required will depend on the size of the nail and the workpiece material.

Begin testing the depth of drive by driving a test nail into the same type of workpiece material used for the actual job.

Drive a test nail with the air pressure set at

It may be possible to achieve the desired depth with air pressure adjustments alone. If finer adjustments are needed, use the drive depth adjustment on the tool.

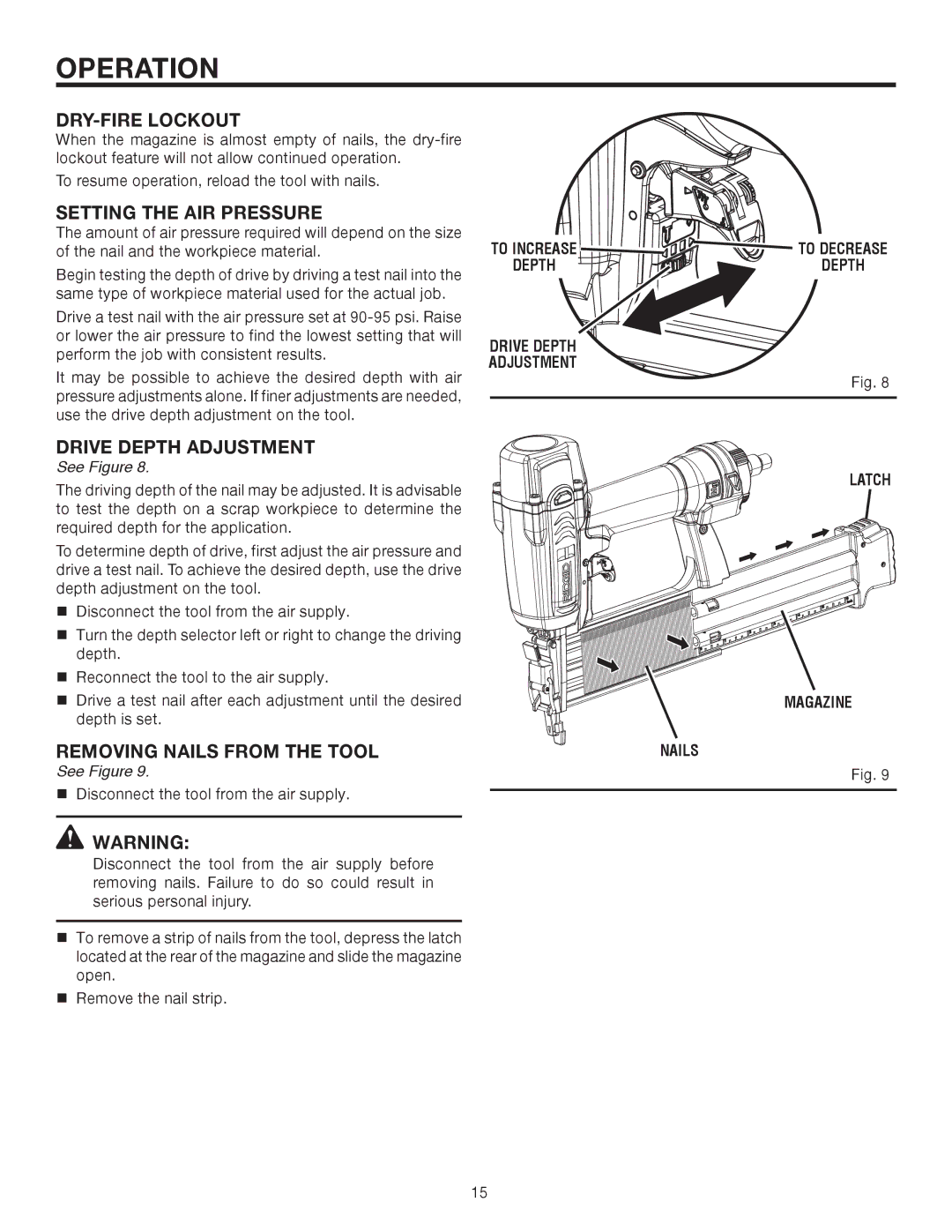

DRIVE DEPTH ADJUSTMENT

See Figure 8.

The driving depth of the nail may be adjusted. It is advisable to test the depth on a scrap workpiece to determine the required depth for the application.

To determine depth of drive, first adjust the air pressure and drive a test nail. To achieve the desired depth, use the drive depth adjustment on the tool.

nDisconnect the tool from the air supply.

nTurn the depth selector left or right to change the driving depth.

nReconnect the tool to the air supply.

nDrive a test nail after each adjustment until the desired depth is set.

REMOVING NAILS FROM THE TOOL

See Figure 9.

nDisconnect the tool from the air supply.

![]() WARNING:

WARNING:

Disconnect the tool from the air supply before removing nails. Failure to do so could result in serious personal injury.

nTo� remove a strip of nails from the tool, depress the latch located at the rear of the magazine and slide the magazine open.

nRemove the nail strip.

TO INCREASE | TO DECREASE |

DEPTH | DEPTH |

DRIVE DEPTH ![]()

![]()

![]()

ADJUSTMENT ![]()

![]()

![]()

![]()

![]()

![]()

Fig. 8

LATCH

MAGAZINE

NAILS

Fig. 9

15