OPERATION

CHUCK REMOVAL

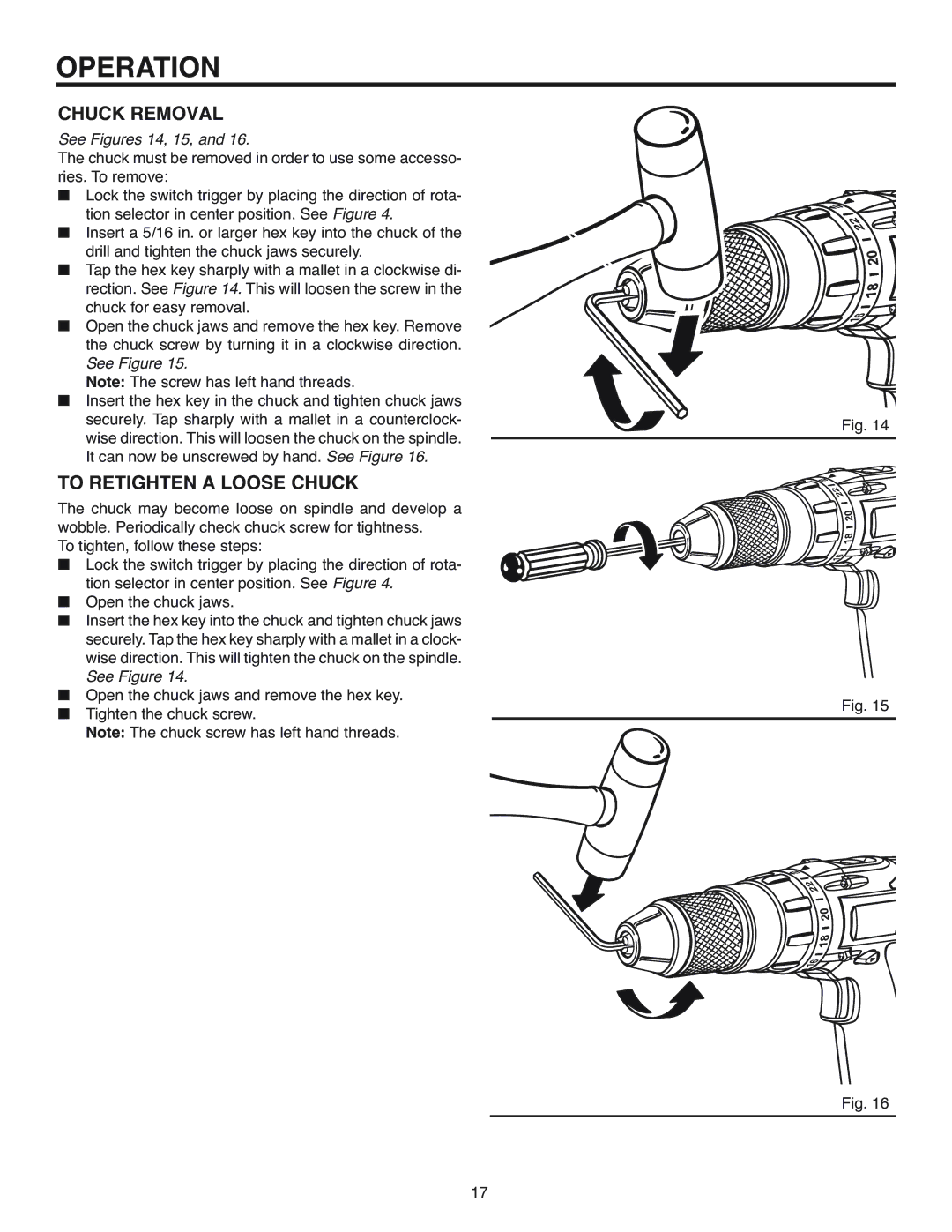

See Figures 14, 15, and 16.

The chuck must be removed in order to use some accesso- ries. To remove:

■Lock the switch trigger by placing the direction of rota- tion selector in center position. See Figure 4.

■Insert a 5/16 in. or larger hex key into the chuck of the drill and tighten the chuck jaws securely.

■Tap the hex key sharply with a mallet in a clockwise di- rection. See Figure 14. This will loosen the screw in the chuck for easy removal.

■Open the chuck jaws and remove the hex key. Remove the chuck screw by turning it in a clockwise direction. See Figure 15.

Note: The screw has left hand threads.

■Insert the hex key in the chuck and tighten chuck jaws securely. Tap sharply with a mallet in a counterclock- wise direction. This will loosen the chuck on the spindle. It can now be unscrewed by hand. See Figure 16.

TO RETIGHTEN A LOOSE CHUCK

The chuck may become loose on spindle and develop a wobble. Periodically check chuck screw for tightness.

To tighten, follow these steps:

■Lock the switch trigger by placing the direction of rota- tion selector in center position. See Figure 4.

■Open the chuck jaws.

■Insert the hex key into the chuck and tighten chuck jaws securely. Tap the hex key sharply with a mallet in a clock- wise direction. This will tighten the chuck on the spindle. See Figure 14.

■Open the chuck jaws and remove the hex key.

■Tighten the chuck screw.

Note: The chuck screw has left hand threads.

22 ![]()

20 ![]() 18

18 ![]()

![]()

![]() 16

16 ![]()

Fig. 14

22 ![]()

![]()

![]()

20 ![]() 18

18 ![]()

![]()

![]() 16

16 ![]()

Fig. 15

22 ![]()

![]()

![]()

20 ![]()

![]() 18

18 ![]()

![]()

![]() 16

16 ![]()

Fig. 16

17