11. Power | 11. Power |

Connector | Connector |

| 9.Control Circuit |

| Board |

| 4. Control Panel |

Sample filter exit | Sensor Housing |

Air Intake | |

tube | Port |

| 8.Air Detection |

| Sensor |

| InletPressure |

10. Purge | Regulator |

3. Sample filter | |

Pump |

|

Sample filter inlet |

|

valve |

|

Sample Inlet Port

View with Cover Removed | Front View |

Hanger

Serial Number

Location

6.Sample exhaust port

1. Case

Housing screws;

8 total

Rear View

III.Hardware Description

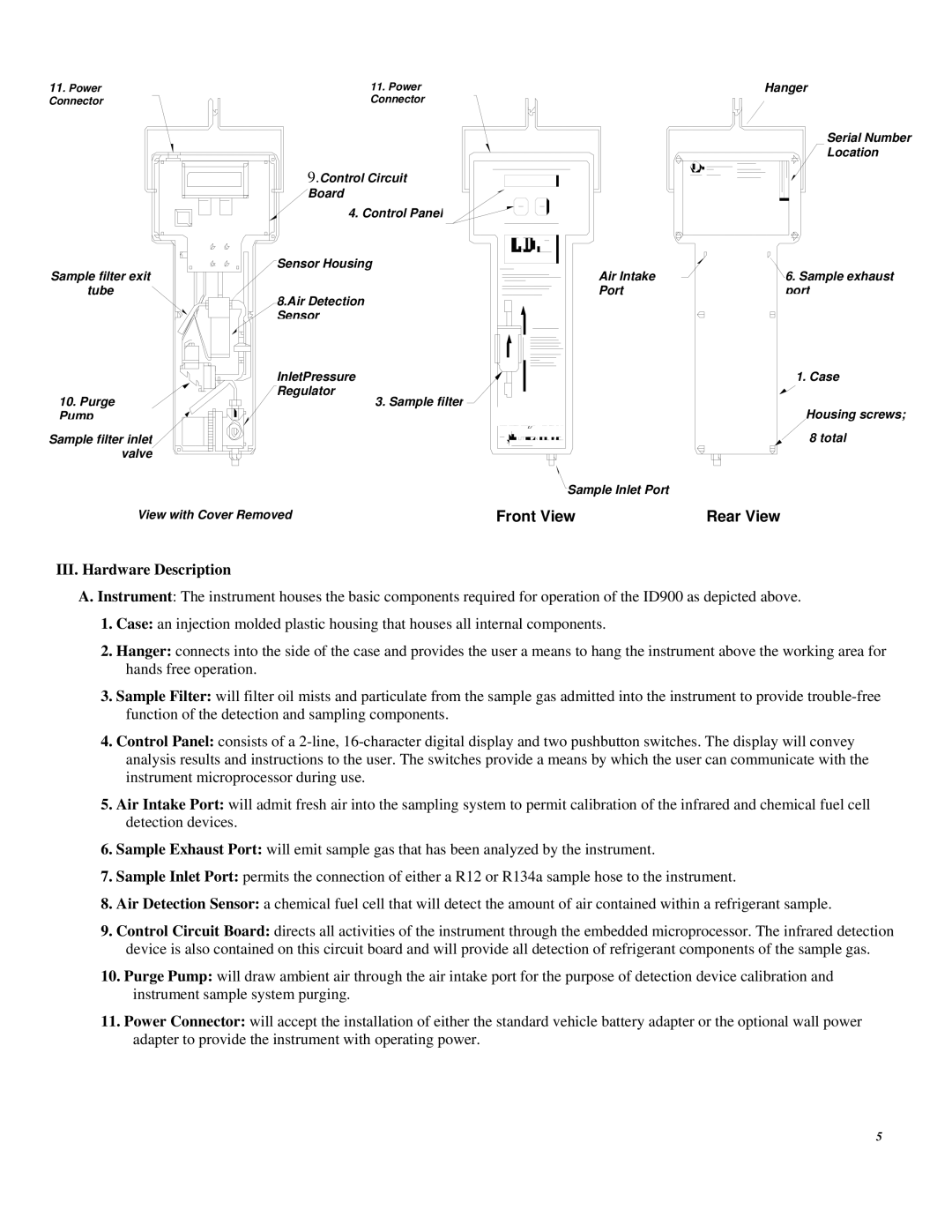

A. Instrument: The instrument houses the basic components required for operation of the ID900 as depicted above.

1.Case: an injection molded plastic housing that houses all internal components.

2.Hanger: connects into the side of the case and provides the user a means to hang the instrument above the working area for hands free operation.

3.Sample Filter: will filter oil mists and particulate from the sample gas admitted into the instrument to provide

4.Control Panel: consists of a

5.Air Intake Port: will admit fresh air into the sampling system to permit calibration of the infrared and chemical fuel cell detection devices.

6.Sample Exhaust Port: will emit sample gas that has been analyzed by the instrument.

7.Sample Inlet Port: permits the connection of either a R12 or R134a sample hose to the instrument.

8.Air Detection Sensor: a chemical fuel cell that will detect the amount of air contained within a refrigerant sample.

9.Control Circuit Board: directs all activities of the instrument through the embedded microprocessor. The infrared detection device is also contained on this circuit board and will provide all detection of refrigerant components of the sample gas.

10.Purge Pump: will draw ambient air through the air intake port for the purpose of detection device calibration and instrument sample system purging.

11.Power Connector: will accept the installation of either the standard vehicle battery adapter or the optional wall power adapter to provide the instrument with operating power.

5