OPERATION

GRINDING AND SANDING

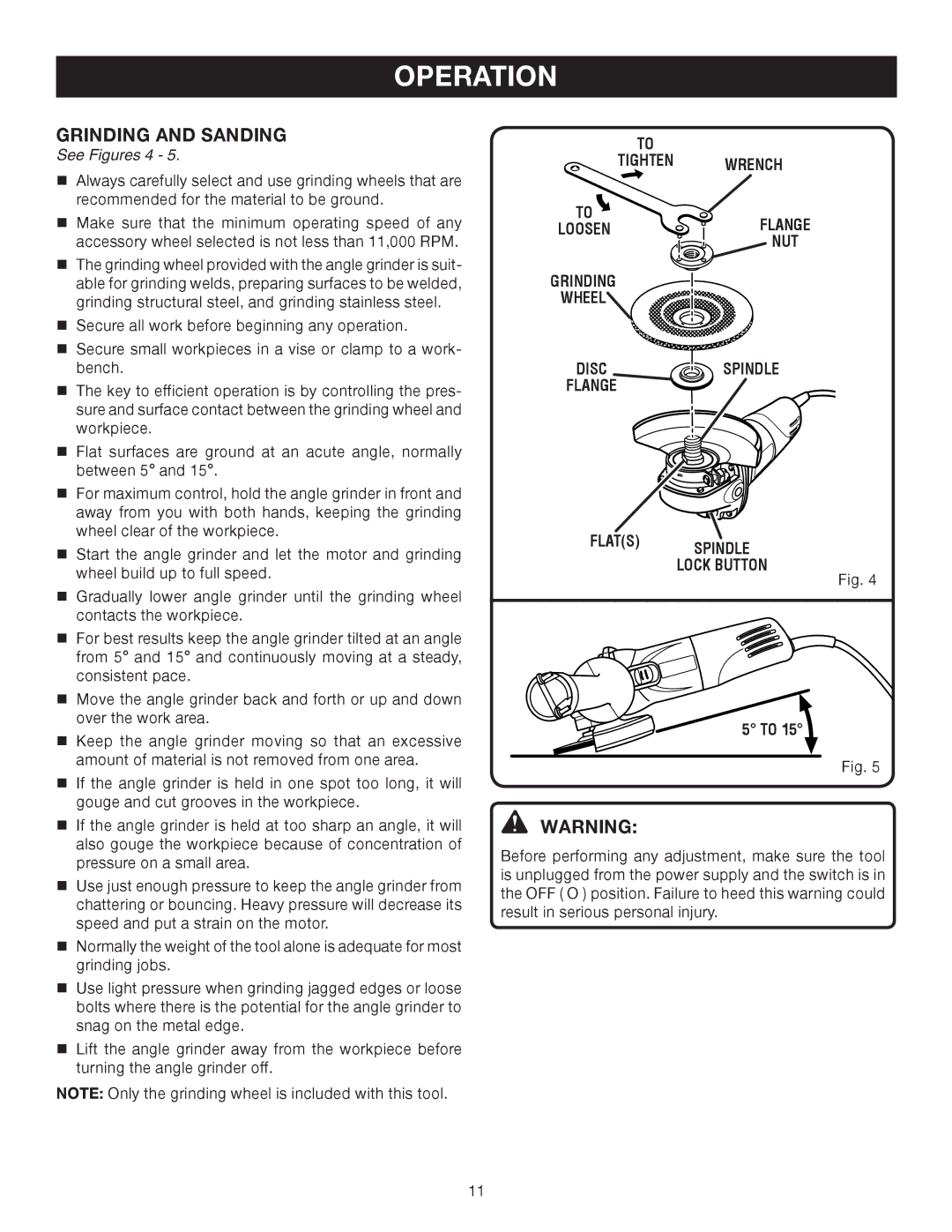

See Figures 4 - 5.

Always carefully select and use grinding wheels that are |

recommended for the material to be ground. |

Make sure that the minimum operating speed of any |

accessory wheel selected is not less than 11,000 RPM. |

The grinding wheel provided with the angle grinder is suit- |

able for grinding welds, preparing surfaces to be welded, |

grinding structural steel, and grinding stainless steel. |

Secure all work before beginning any operation. |

Secure small workpieces in a vise or clamp to a work- |

TO

TIGHTEN

TO ![]()

LOOSEN

GRINDING

WHEEL

WRENCH

FLANGE

NUT

bench. |

The key to efficient operation is by controlling the pres- |

sure and surface contact between the grinding wheel and |

workpiece. |

Flat surfaces are ground at an acute angle, normally |

between 5° and 15°. |

For maximum control, hold the angle grinder in front and |

away from you with both hands, keeping the grinding |

wheel clear of the workpiece. |

Start the angle grinder and let the motor and grinding |

wheel build up to full speed. |

Gradually lower angle grinder until the grinding wheel |

contacts the workpiece. |

For best results keep the angle grinder tilted at an angle |

from 5° and 15° and continuously moving at a steady, |

consistent pace. |

Move the angle grinder back and forth or up and down |

over the work area. |

Keep the angle grinder moving so that an excessive |

amount of material is not removed from one area. |

If the angle grinder is held in one spot too long, it will |

gouge and cut grooves in the workpiece. |

If the angle grinder is held at too sharp an angle, it will |

also gouge the workpiece because of concentration of |

pressure on a small area. |

Use just enough pressure to keep the angle grinder from |

chattering or bouncing. Heavy pressure will decrease its |

speed and put a strain on the motor. |

Normally the weight of the tool alone is adequate for most |

grinding jobs. |

Use light pressure when grinding jagged edges or loose |

bolts where there is the potential for the angle grinder to |

snag on the metal edge. |

Lift the angle grinder away from the workpiece before |

turning the angle grinder off. |

NOTE: Only the grinding wheel is included with this tool.

DISC | SPINDLE |

FLANGE |

|

FLAT(S) SPINDLE

LOCK BUTTON

Fig. 4

5° TO 15° ![]()

Fig. 5

WARNING:

Before performing any adjustment, make sure the tool is unplugged from the power supply and the switch is in the OFF ( O ) position. Failure to heed this warning could result in serious personal injury.

11