OPERATION

CROSS CUTTING/RIP CUTTING | TOP VIEW OF SAW | |

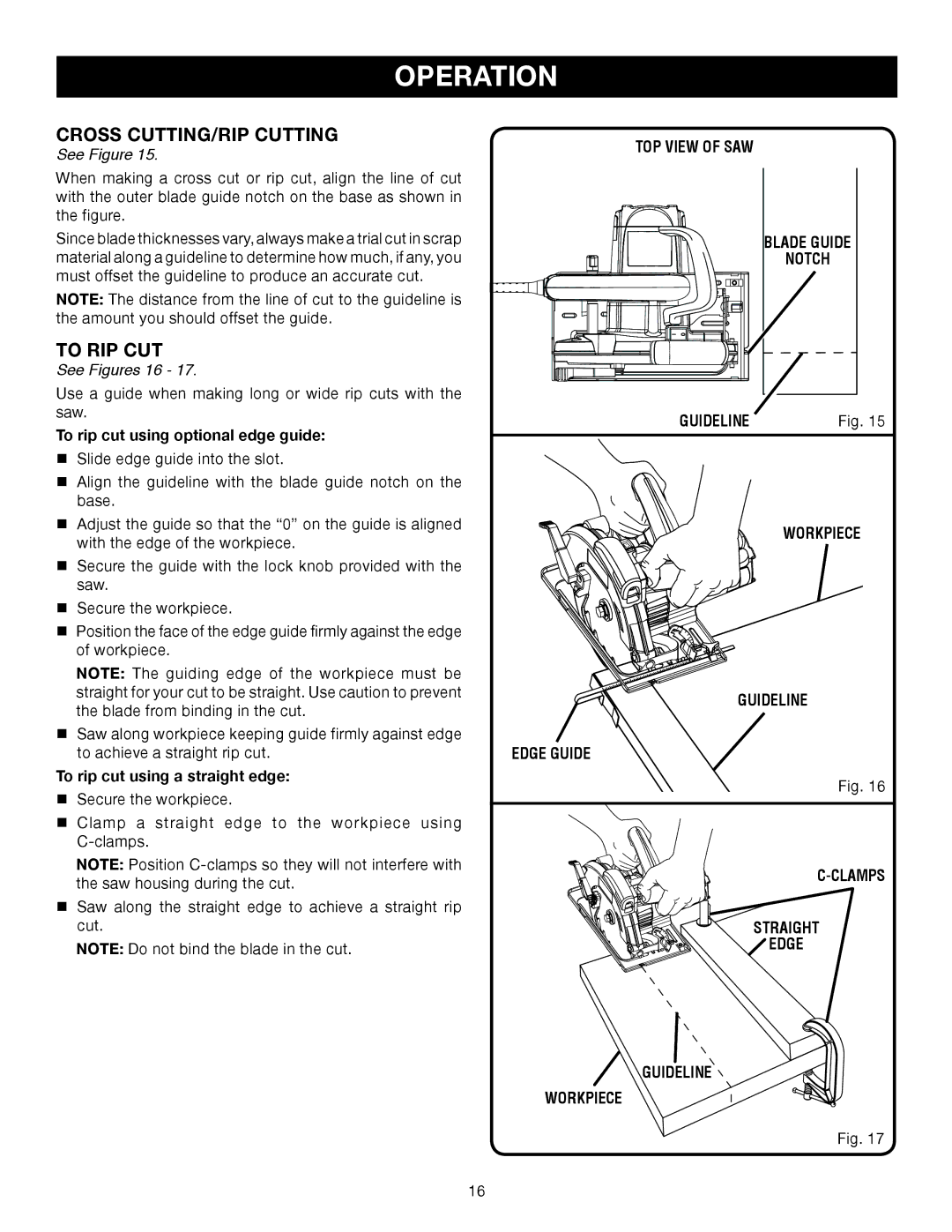

See Figure 15. | ||

| ||

When making a cross cut or rip cut, align the line of cut |

| |

with the outer blade guide notch on the base as shown in |

| |

the figure. |

| |

Since blade thicknesses vary, always make a trial cut in scrap | BLADE GUIDE | |

material along a guideline to determine how much, if any, you | NOTCH | |

must offset the guideline to produce an accurate cut. |

|

NOTE: The distance from the line of cut to the guideline is the amount you should offset the guide.

TO RIP CUT |

|

| |

See Figures 16 - 17. |

|

| |

Use a guide when making long or wide rip cuts with the |

|

| |

saw. | GUIDELINE | Fig. 15 | |

To rip cut using optional edge guide: | |||

|

| ||

Slide edge guide into the slot. |

|

| |

Align the guideline with the blade guide notch on the |

|

| |

base. |

|

| |

Adjust the guide so that the “0” on the guide is aligned |

| WORKPIECE | |

with the edge of the workpiece. |

| ||

|

| ||

Secure the guide with the lock knob provided with the |

|

| |

saw. |

|

| |

Secure the workpiece. |

|

| |

Position the face of the edge guide firmly against the edge |

|

| |

of workpiece. |

|

| |

NOTE: The guiding edge of the workpiece must be |

|

| |

straight for your cut to be straight. Use caution to prevent | GUIDELINE | ||

the blade from binding in the cut. | |||

|

| ||

Saw along workpiece keeping guide firmly against edge

to achieve a straight rip cut. |

| EDGE GUIDE |

To rip cut using a straight edge: |

| Fig. 16 |

Secure the workpiece. |

| |

|

| |

Clamp a straight edge to the workpiece | using |

|

|

| |

NOTE: Position | ||

the saw housing during the cut. |

| |

|

| |

Saw along the straight edge to achieve a straight rip |

| |

cut. |

| STRAIGHT |

NOTE: Do not bind the blade in the cut. |

| EDGE |

GUIDELINE

WORKPIECE

Fig. 17

16