assembly

Installing/changing worklight bulb

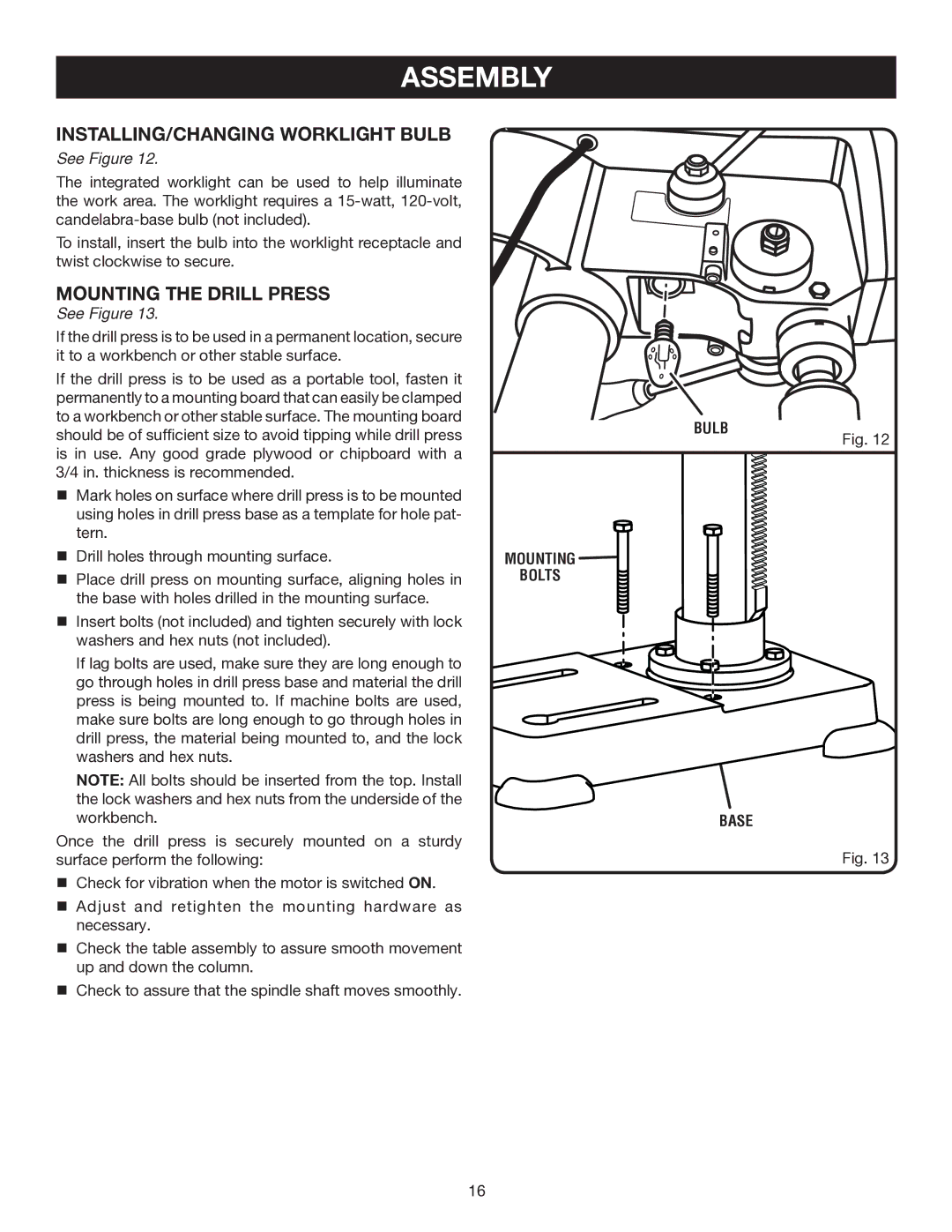

See Figure 12.

The integrated worklight can be used to help illuminate the work area. The worklight requires a

candelabra

To install, insert the bulb into the worklight receptacle and twist clockwise to secure.

Mounting the Drill press

See Figure 13.

If the drill press is to be used in a permanent location, secure it to a workbench or other stable surface.

If the drill press is to be used as a portable tool, fasten it |

|

| |

permanently to a mounting board that can easily be clamped |

|

| |

to a workbench or other stable surface. The mounting board | bulb |

| |

should be of sufficient size to avoid tipping while drill press | Fig. 12 | ||

| |||

is in use. Any good grade plywood or chipboard with a |

| ||

|

| ||

3/4 in. thickness is recommended. |

|

| |

■ Mark holes on surface where drill press is to be mounted |

|

| |

using holes in drill press base as a template for hole pat- |

|

| |

tern. |

|

| |

■ Drill holes through mounting surface. | mounting |

| |

■ Place drill press on mounting surface, aligning holes in | bolts |

| |

the base with holes drilled in the mounting surface. |

|

|

■ Insert bolts (not included) and tighten securely with lock washers and hex nuts (not included).

If lag bolts are used, make sure they are long enough to

go through holes in drill press base and material the drill ![]() press is being mounted to. If machine bolts are used,

press is being mounted to. If machine bolts are used,

make sure bolts are long enough to go through holes in drill press, the material being mounted to, and the lock

washers and hex nuts.

Note: All bolts should be inserted from the top. Install |

|

the lock washers and hex nuts from the underside of the |

|

workbench. | base |

Once the drill press is securely mounted on a sturdy | Fig. 13 |

surface perform the following: |

Check for vibration when the motor is switched ON.

Adjust and retighten the mounting hardware as

necessary .

Check the table assembly to assure smooth movement up and down the column.

Check to assure that the spindle shaft moves smoothly.

16