SAFETY INSTRUCTIONS

Type of cutting blades

The cutting blade should be marked with the same or a higher speed than that stated on the machine’s rating plate. Never use a cutting blade with a lower speed rating than what is stated on the machine’s rating plate.

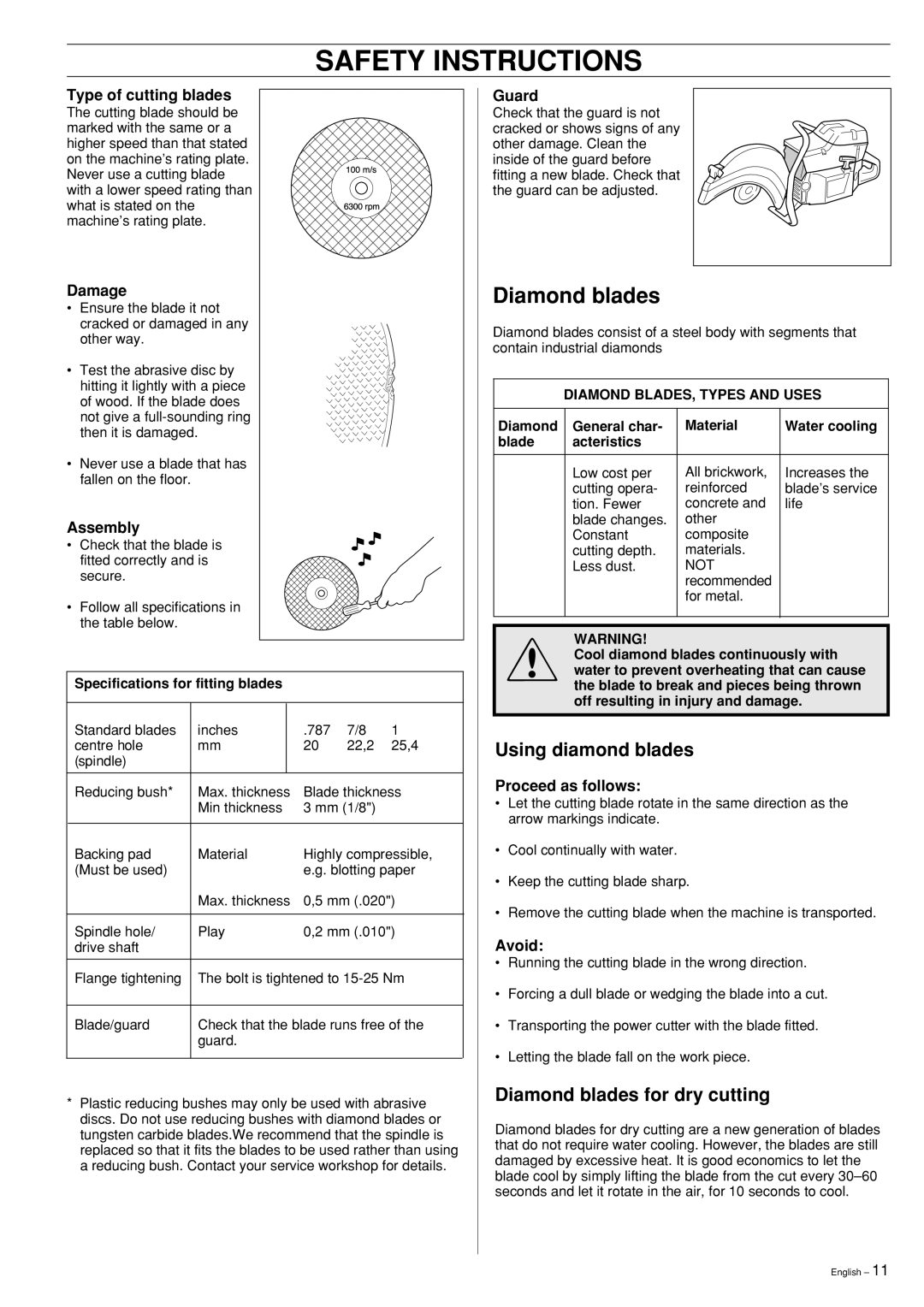

Damage

•Ensure the blade it not cracked or damaged in any other way.

• Test the abrasive disc by hitting it lightly with a piece of wood. If the blade does not give a

•Never use a blade that has fallen on the floor.

Assembly

• Check that the blade is

fitted correctly and is secure.

• Follow all specifications in the table below.

Specifications for fitting blades

| Standard blades | inches |

| .787 | 7/8 | 1 |

|

| centre hole | mm |

| 20 | 22,2 | 25,4 |

|

| (spindle) |

|

|

|

|

|

|

|

|

|

|

|

| ||

| Reducing bush* | Max. thickness | Blade thickness |

| |||

|

| Min thickness | 3 mm (1/8") |

|

| ||

|

|

|

|

|

| ||

| Backing pad | Material | Highly compressible, |

| |||

| (Must be used) |

|

| e.g. blotting paper |

| ||

|

| Max. thickness | 0,5 mm (.020") |

| |||

|

|

|

|

|

| ||

| Spindle hole/ | Play | 0,2 mm (.010") |

| |||

| drive shaft |

|

|

|

|

|

|

|

|

|

|

| |||

| Flange tightening | The bolt is tightened to |

| ||||

|

|

|

|

| |||

| Blade/guard | Check that the blade runs free of the |

| ||||

|

| guard. |

|

|

|

| |

|

|

|

|

|

|

|

|

*Plastic reducing bushes may only be used with abrasive discs. Do not use reducing bushes with diamond blades or tungsten carbide blades.We recommend that the spindle is replaced so that it fits the blades to be used rather than using a reducing bush. Contact your service workshop for details.

Guard

Check that the guard is not cracked or shows signs of any other damage. Clean the inside of the guard before fitting a new blade. Check that the guard can be adjusted.

Diamond blades

Diamond blades consist of a steel body with segments that contain industrial diamonds

DIAMOND BLADES, TYPES AND USES

Diamond | General char- | Material | Water cooling |

blade | acteristics |

|

|

|

|

|

|

| Low cost per | All brickwork, | Increases the |

| cutting opera- | reinforced | blade’s service |

| tion. Fewer | concrete and | life |

| blade changes. | other |

|

| Constant | composite |

|

| cutting depth. | materials. |

|

| Less dust. | NOT |

|

|

| recommended |

|

|

| for metal. |

|

|

|

|

|

!WARNING!

Cool diamond blades continuously with water to prevent overheating that can cause the blade to break and pieces being thrown off resulting in injury and damage.

Using diamond blades

Proceed as follows:

•Let the cutting blade rotate in the same direction as the arrow markings indicate.

•Cool continually with water.

•Keep the cutting blade sharp.

•Remove the cutting blade when the machine is transported.

Avoid:

•Running the cutting blade in the wrong direction.

•Forcing a dull blade or wedging the blade into a cut.

•Transporting the power cutter with the blade fitted.

•Letting the blade fall on the work piece.

Diamond blades for dry cutting

Diamond blades for dry cutting are a new generation of blades that do not require water cooling. However, the blades are still damaged by excessive heat. It is good economics to let the blade cool by simply lifting the blade from the cut every

English – 11