OPERATION

Adjusting TORQUE

See Figure 3.

There are twelve torque indicator settings located on the front of the screwdriver.

Rotate adjustment ring to desired setting, aligning num- ber on adjustment ring with arrow on housing.

•1 - 2 For driving small screws

•3 - 4 For driving screws into soft material

•5 - 7 For driving screws into soft and hard materials

•8 - 9 For driving screws into hard wood

•10 - 11 For driving large screws

• | For full power applications |

DIRECTION OF ROTATION SELECTOR

(FORWARD/REVERSE/center lock)

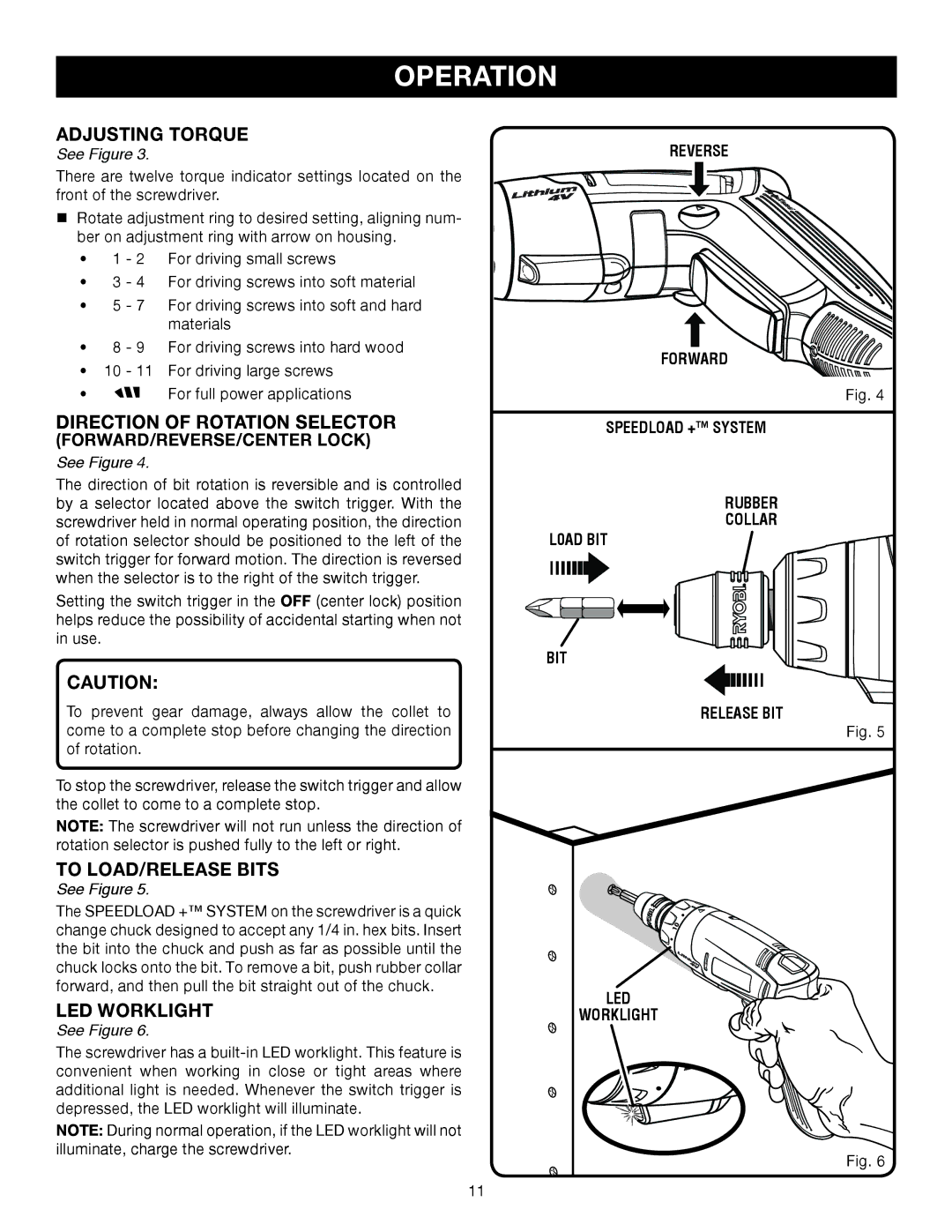

See Figure 4.

The direction of bit rotation is reversible and is controlled by a selector located above the switch trigger. With the screwdriver held in normal operating position, the direction of rotation selector should be positioned to the left of the switch trigger for forward motion. The direction is reversed when the selector is to the right of the switch trigger.

Setting the switch trigger in the OFF (center lock) position helps reduce the possibility of accidental starting when not in use.

CAUTION:

To prevent gear damage, always allow the collet to come to a complete stop before changing the direction of rotation.

To stop the screwdriver, release the switch trigger and allow the collet to come to a complete stop.

NOTE: The screwdriver will not run unless the direction of rotation selector is pushed fully to the left or right.

TO LOAD/RELEASE BITS

See Figure 5.

The SPEEDLOAD +™ SYSTEM on the screwdriver is a quick change chuck designed to accept any 1/4 in. hex bits. Insert the bit into the chuck and push as far as possible until the chuck locks onto the bit. To remove a bit, push rubber collar forward, and then pull the bit straight out of the chuck.

LED WORKLIGHT

See Figure 6.

The screwdriver has a

NOTE: During normal operation, if the LED worklight will not illuminate, charge the screwdriver.

reverse

forward

Fig. 4

SPEEDLOAD +™ SYSTEM

RUBBER

COLLAR

L0AD BIT

BIT

RELEASE BIT

Fig. 5

LED

WORKLIGHT

Fig. 6

11