OPERATION

BEVEL CUTTING

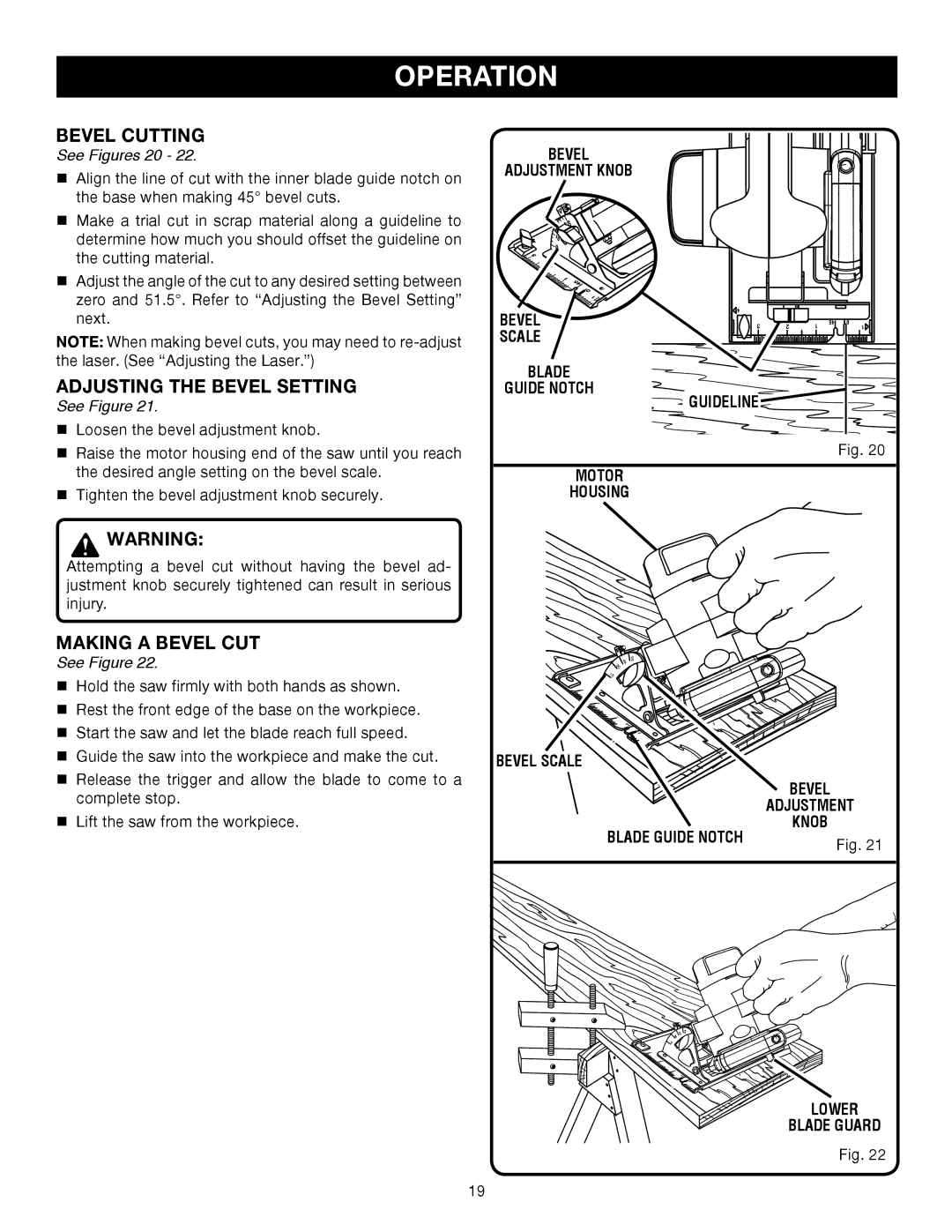

See Figures 20 - 22.

nAlign the line of cut with the inner blade guide notch on the base when making 45° bevel cuts.

nMake a trial cut in scrap material along a guideline to determine how much you should offset the guideline on the cutting material.

nAdjust the angle of the cut to any desired setting between zero and 51.5°. Refer to “Adjusting the Bevel Setting” next.

NOTE: When making bevel cuts, you may need to

BEVEL

ADJUSTMENT KNOB

BEVEL

SCALE

4 |

|

3 | 2 |

145

0 | 1 |

|

ADJUSTING THE BEVEL SETTING

See Figure 21.

nLoosen the bevel adjustment knob.

nRaise the motor housing end of the saw until you reach the desired angle setting on the bevel scale.

nTighten the bevel adjustment knob securely.

WARNING:

Attempting a bevel cut without having the bevel ad- justment knob securely tightened can result in serious injury.

MAKING A BEVEL CUT

BLADE

GUIDE NOTCH

MOTOR

HOUSING

GUIDELINE

Fig. 20

See Figure 22.

nHold the saw firmly with both hands as shown.

nRest the front edge of the base on the workpiece.

nStart the saw and let the blade reach full speed.

nGuide the saw into the workpiece and make the cut.

nRelease the trigger and allow the blade to come to a complete stop.

nLift the saw from the workpiece.

| 5 |

45 | 0 |

3 |

|

0 |

|

15 |

|

3 |

|

2 |

|

1 |

|

54 |

|

| 0 |

BEVEL SCALE |

|

| BEVEL | |

| ADJUSTMENT | |

BLADE GUIDE NOTCH | KNOB | |

Fig. 21 | ||

|

4 | 5 |

5 | 0 |

3 0

15 ![]()

![]() 3

3

![]() 2

2

![]() 1

1

54

0

LOWER

BLADE GUARD

Fig. 22

19