MAINTENANCE

![]() WARNING:

WARNING:

Improper chain sharpening increases the potential of kickback.

![]() WARNING:

WARNING:

Failure to replace or repair damaged chain can cause serious injury.

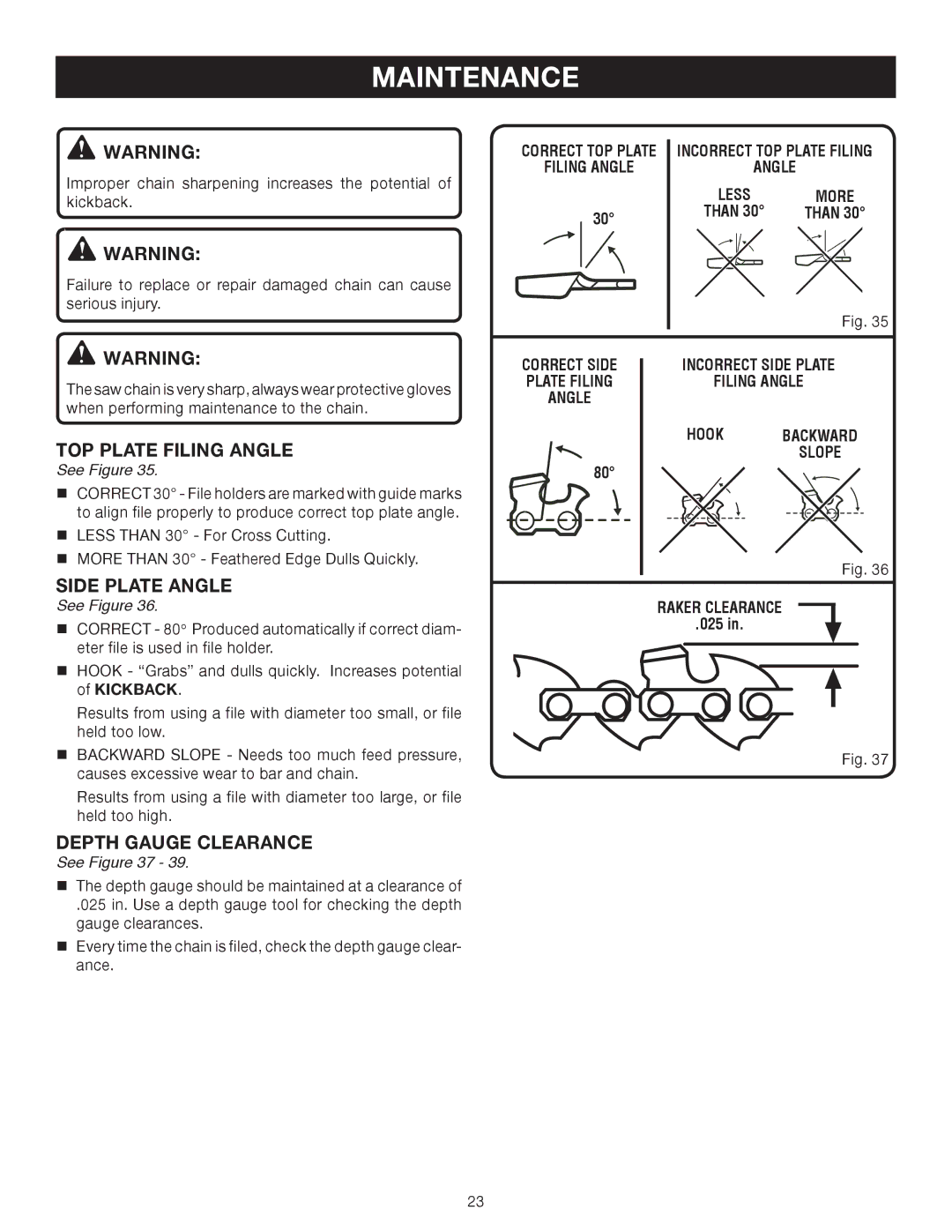

correcT TOP PLATE

FILING ANGLE

30°

INcorrecT TOP PLATE FILING

ANGLE

LESS | MORE |

THAN 30° | THAN 30° |

Fig. 35

![]() WARNING:

WARNING:

The saw chain is very sharp, always wear protective gloves when performing maintenance to the chain.

Top Plate Filing Angle

See Figure 35.

CORRECT 30° - File holders are marked with guide marks to align file properly to produce correct top plate angle.

LESS THAN 30° - For Cross Cutting.

MORE THAN 30° - Feathered Edge Dulls Quickly.

Side Plate Angle

See Figure 36.

CORRECT - 80o Produced automatically if correct diam- eter file is used in file holder.

HOOK - “Grabs” and dulls quickly. Increases potential of KICKBACK.

Results from using a file with diameter too small, or file held too low.

BACKWARD SLOPE - Needs too much feed pressure, causes excessive wear to bar and chain.

Results from using a file with diameter too large, or file held too high.

Depth Gauge Clearance

See Figure 37 - 39.

The depth gauge should be maintained at a clearance of

.025 in. Use a depth gauge tool for checking the depth gauge clearances.

Every time the chain is filed, check the depth gauge clear- ance.

correct SIDE | INcorrect SIDE PLATE | |

PLATE FILING | FILING ANGLE | |

ANGLE |

|

|

| HOOK | BACKWARD |

|

| SLOPE |

80° |

|

|

Fig. 36

raker clearance

.025 in.

Fig. 37

23