OPERATION

chips, and a rougher finish. Bigger chips also require more power, which could result in the trimmer motor becoming overloaded.

Under extreme

Your trimmer is an extremely

Three things that cause “force feeding” are cutter size,

You can always detect “force feeding” by the sound of the motor. Its

TOO SLOW FEEDING

It is also possible to spoil a cut by moving the trimmer for- ward too slowly. When it is advanced into the work too slowly, a revolving cutter does not dig into new wood fast enough to take a bite; instead, it simply scrapes away

In addition, it is more difficult to control a trimmer when the cutter is scraping instead of cutting. With practically no load on the motor the cutter will be revolving at close to top RPM, and will have a much greater than normal tendency to bounce off the sides of the cut (especially, if the wood has a pronounced grain with hard and soft areas). As a result, the cut produced may have sides that are rippled instead of straight.

DEPTH OF CUT

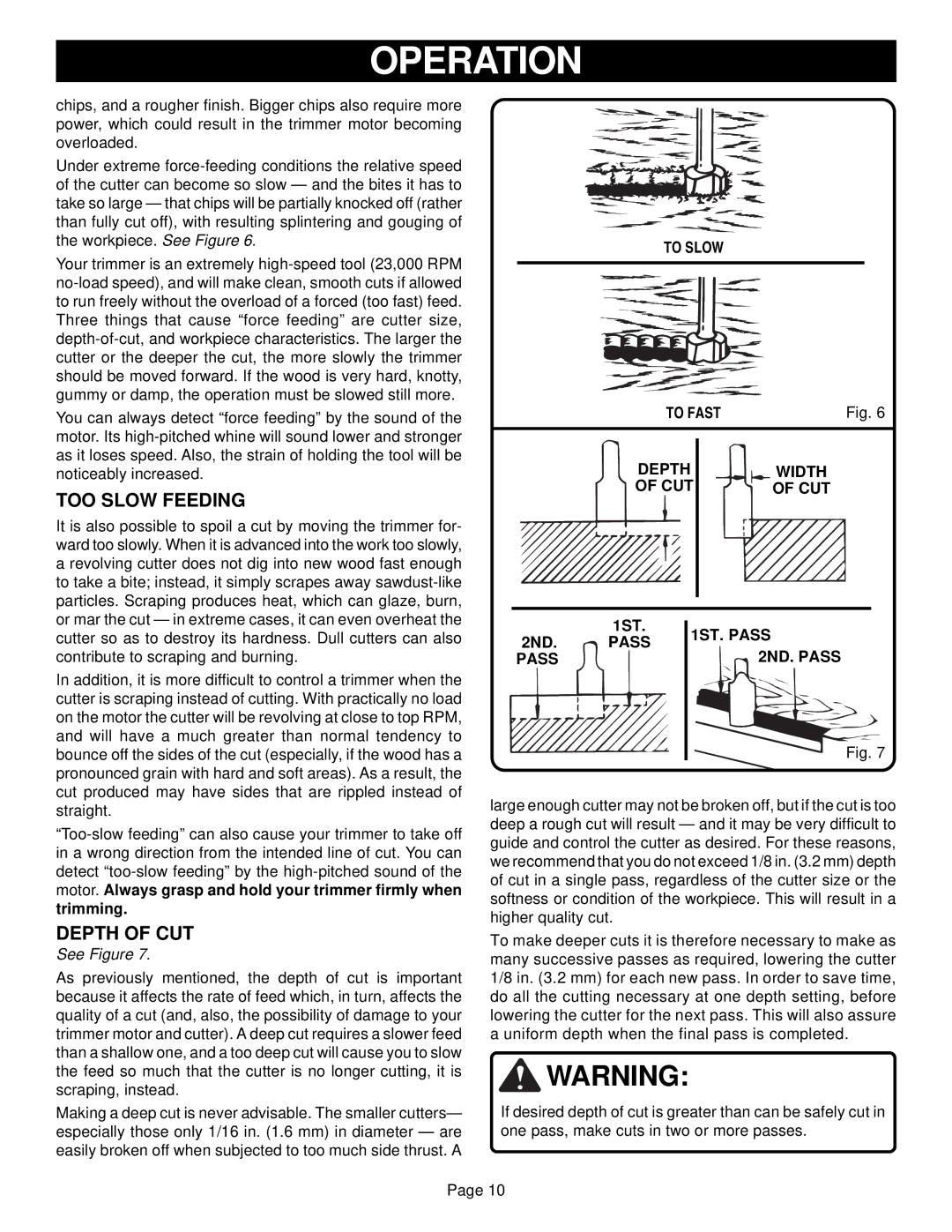

See Figure 7.

As previously mentioned, the depth of cut is important because it affects the rate of feed which, in turn, affects the quality of a cut (and, also, the possibility of damage to your trimmer motor and cutter). A deep cut requires a slower feed than a shallow one, and a too deep cut will cause you to slow the feed so much that the cutter is no longer cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller cutters— especially those only 1/16 in. (1.6 mm) in diameter — are easily broken off when subjected to too much side thrust. A

TO SLOW

TO FAST | Fig. 6 |

DEPTH | WIDTH |

OF CUT | OF CUT |

| 1ST. | 1ST. PASS | |

2ND. | PASS | ||

2ND. PASS | |||

PASS |

|

Fig. 7 |

large enough cutter may not be broken off, but if the cut is too deep a rough cut will result — and it may be very difficult to guide and control the cutter as desired. For these reasons, we recommend that you do not exceed 1/8 in. (3.2 mm) depth of cut in a single pass, regardless of the cutter size or the softness or condition of the workpiece. This will result in a higher quality cut.

To make deeper cuts it is therefore necessary to make as many successive passes as required, lowering the cutter 1/8 in. (3.2 mm) for each new pass. In order to save time, do all the cutting necessary at one depth setting, before lowering the cutter for the next pass. This will also assure a uniform depth when the final pass is completed.

![]() WARNING:

WARNING:

If desired depth of cut is greater than can be safely cut in one pass, make cuts in two or more passes.

Page 10