RPBV2500 specifications

The Ryobi Outdoor RPBV2500 is a powerful and versatile backpack blower that reflects Ryobi's commitment to innovation and customer satisfaction in outdoor power equipment. Designed for both residential and commercial users, this model combines efficiency, ease of use, and smart technologies to make yard work a breeze.One of the standout features of the RPBV2500 is its robust powerhead, which houses a reliable 25cc 2-cycle engine. This engine provides impressive air velocity and volume, making it suitable for tackling various outdoor cleaning tasks, from clearing leaves and debris to managing grass clippings. With air speeds of up to 200 miles per hour, this blower can easily handle even the toughest cleanup jobs, ensuring that your garden, lawn, or patio remains pristine.

In terms of design, the RPBV2500 features an ergonomic harness system that distributes weight evenly across the shoulders and back. This design minimizes operator fatigue, allowing you to work for extended periods without discomfort. The adjustable straps and padded back offer extra comfort and stability, enhancing the overall user experience.

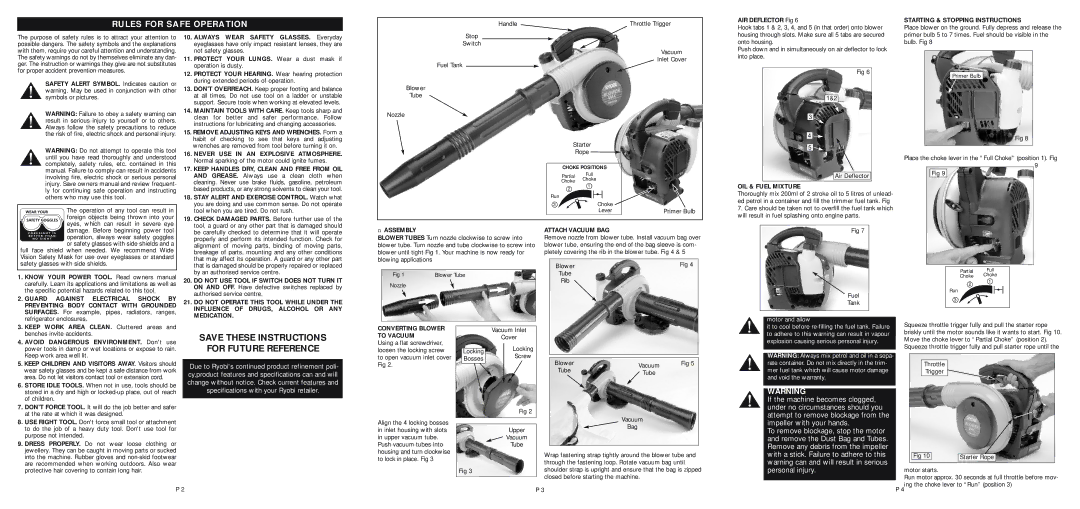

The blower incorporates a number of user-friendly technologies, including a simple start system that allows for quick ignition. The controls are conveniently located, ensuring easy access while in operation. The throttle response is also smooth, enabling users to smoothly adjust air speeds based on the specific task at hand.

Another impressive characteristic of the RPBV2500 is its versatility. It comes equipped with a variety of nozzle attachments to optimize performance for different applications, from sweeping debris off sidewalks to blowing leaves off your lawn. This adaptability makes it an essential tool for homeowners and landscapers alike.

The Ryobi RPBV2500 is also designed with durability in mind. Constructed with high-quality materials, it can withstand the rigors of outdoor work without compromising performance. This blower is ideal for those who are looking for a dependable tool to meet their yard care needs.

Overall, the Ryobi Outdoor RPBV2500 backpack blower stands out for its combination of power, comfort, and adaptability. Whether you're maintaining a residential yard or managing a larger landscape, this blower offers features and performance that make outdoor cleaning tasks efficient and effective, making it a valuable addition to your outdoor equipment arsenal.