v a l i d a t i o n

VALIDATION

As a leader in commercial, refrigeration, energy and environmental products, SANYO offers a robust source of proven technologies and technical services deployed throughout a range of biomedical and medical research products.

Pioneering developments in consumer and industrial products are applied to all SANYO products through the devel- opment model of Vertical Component Integration™. Because many of our key component parts are designed and built by SANYO, we offer only the most precise and

Detailed Validation Support Package Sanyo also offers detailed protocols in- cluding all required specifications manu- als and support documents. This package will assist your validation team in the qualification process, greatly reducing the time required to complete the entire validation.

Sanyo validation systems are calibrated and maintained to the highest quality standards, while providing and retaining detailed records for all tested equipment.

As the manufacturer we are the most knowledgeable on our equipment. We offer validation services for Sanyo equip- ment and a total solution in fulfilling other regulatory requirement.

VALIDATION SOLUTIONS

Turn Key Solutions available for:

•Ultra low freezers

•Cryogenic freezers

•Pharmaceutical refrigerators

•Incubators

•Autoclaves

Sanyo can assist throughout the entire process from helping you to choose your equipment through the extended war- ranty and service contract options to keep your equipment running. We help you match the appropriate equipment to your requirements (DQ) as well as arranging inside delivery and setup (commissioning) of the equipment.

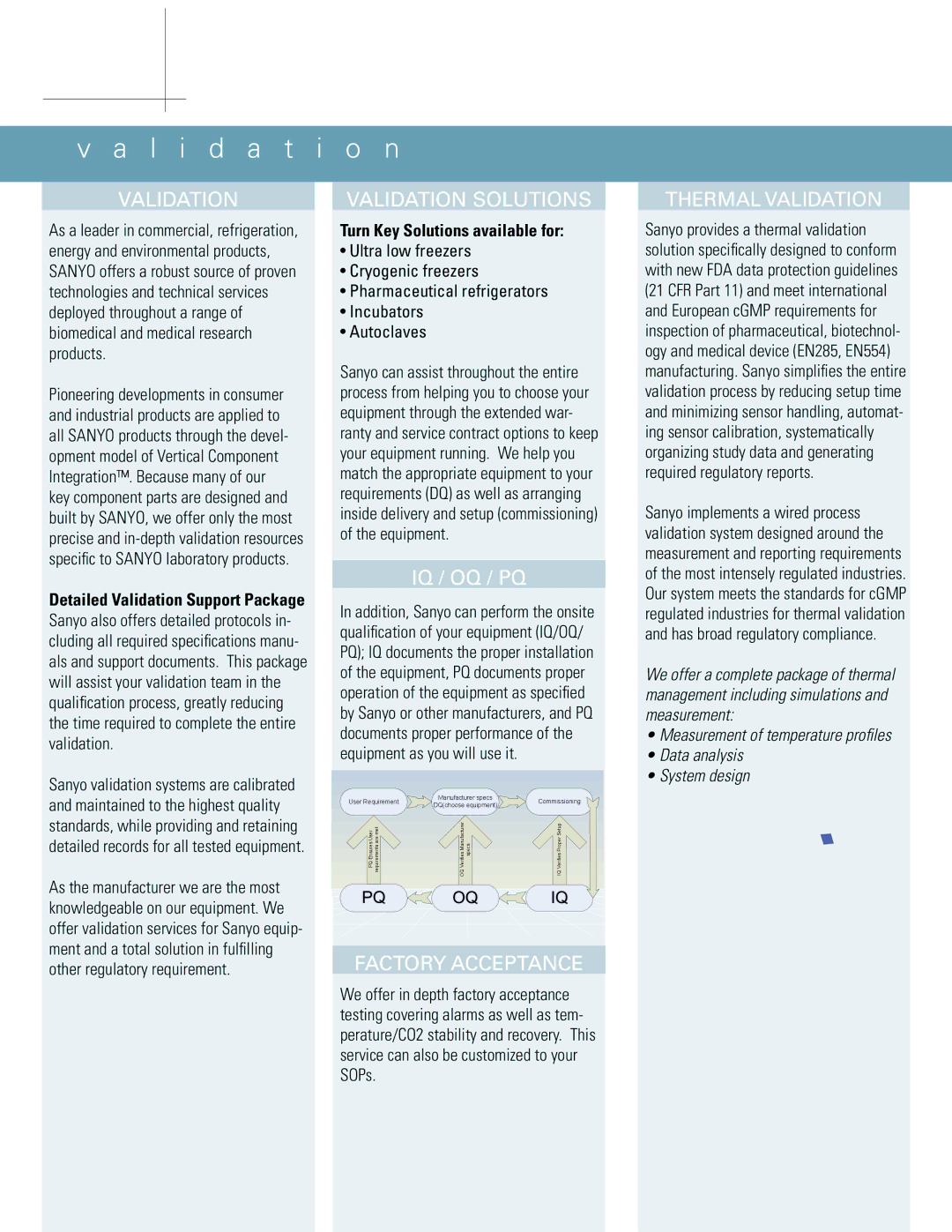

IQ / OQ / PQ

In addition, Sanyo can perform the onsite qualification of your equipment (IQ/OQ/ PQ); IQ documents the proper installation of the equipment, PQ documents proper operation of the equipment as specified by Sanyo or other manufacturers, and PQ documents proper performance of the equipment as you will use it.

User Requirement | Manufacturer specs | Commissioning | |

DQ(choose equipment) | |||

|

| ||

PQ Ensures User requirements are met | OQ Verifies Manufacturer specs | IQ Verifies Proper Setup |

FACTORY ACCEPTANCE

We offer in depth factory acceptance testing covering alarms as well as tem- perature/CO2 stability and recovery. This service can also be customized to your SOPs.

THERMAL VALIDATION

Sanyo provides a thermal validation solution specifically designed to conform with new FDA data protection guidelines (21 CFR Part 11) and meet international and European cGMP requirements for inspection of pharmaceutical, biotechnol- ogy and medical device (EN285, EN554) manufacturing. Sanyo simplifies the entire validation process by reducing setup time and minimizing sensor handling, automat- ing sensor calibration, systematically organizing study data and generating required regulatory reports.

Sanyo implements a wired process validation system designed around the measurement and reporting requirements of the most intensely regulated industries. Our system meets the standards for cGMP regulated industries for thermal validation and has broad regulatory compliance.

We offer a complete package of thermal management including simulations and measurement:

•Measurement of temperature profiles

•Data analysis

•System design