10.Install the new belt covers and secure. See items number 1 and number 21 on page 8 of the Blower Mounting Components section in the Illustrated Parts List for proper installation.

11.Install the LH & RH hopper mounting brackets to the outside of the frame on the rear of the machine and secure using six (6)

the rear holes provided in the RH hopper mounting bracket at this time

RH

Hopper

Mounting

Bracket

Rear Frame

Elastic Stop Nut

FIGURE

12.Remove the upper hex head bolt and serrated flange nut securing the support bracket to the frame of the machine. Retain the serrated flange nut for

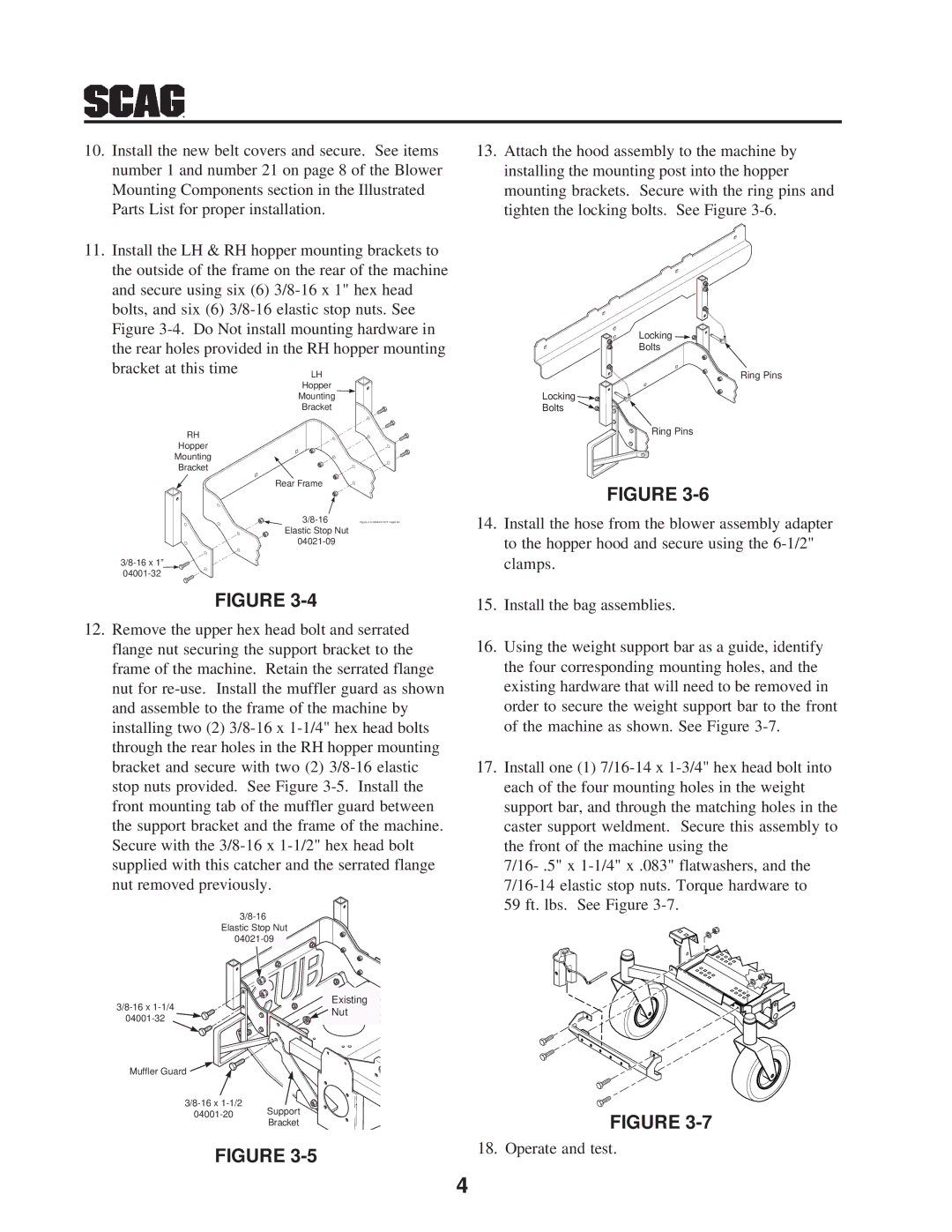

13.Attach the hood assembly to the machine by installing the mounting post into the hopper mounting brackets. Secure with the ring pins and tighten the locking bolts. See Figure

Locking ![]()

![]()

Bolts

Ring Pins

Locking ![]()

![]()

Bolts

Ring Pins

FIGURE

14.Install the hose from the blower assembly adapter to the hopper hood and secure using the

15.Install the bag assemblies.

16.Using the weight support bar as a guide, identify the four corresponding mounting holes, and the existing hardware that will need to be removed in order to secure the weight support bar to the front of the machine as shown. See Figure

17.Install one (1)

| Existing | ||

| Nut | ||

| |||

|

| ||

Muffler Guard |

|

| |

Support |

| ||

FIGURE | |||

Bracket | |||

|

FIGURE | 18. Operate and test. |

|

4