Section 6

If you turn the nut too much, you will com- press the spring, making too much end play. Go to step 4.

4.If the drive wheels rotate in rearward travel direction, turn the adjustment bolt (Figure

5.Check the adjustment of the right foot pedal for full forward speed. The bottom of the foot pedal should be 1/4 inch from the top of the foot plate (See Figure

To make an adjustment, loosen the jam nut at the pump control bellcrank (Figure

6.Start the engine. The drive wheels should rotate only when the forward/reverse foot pedal is depressed.

6.3THROTTLE CONTROL LINKAGE ADJUSTMENT

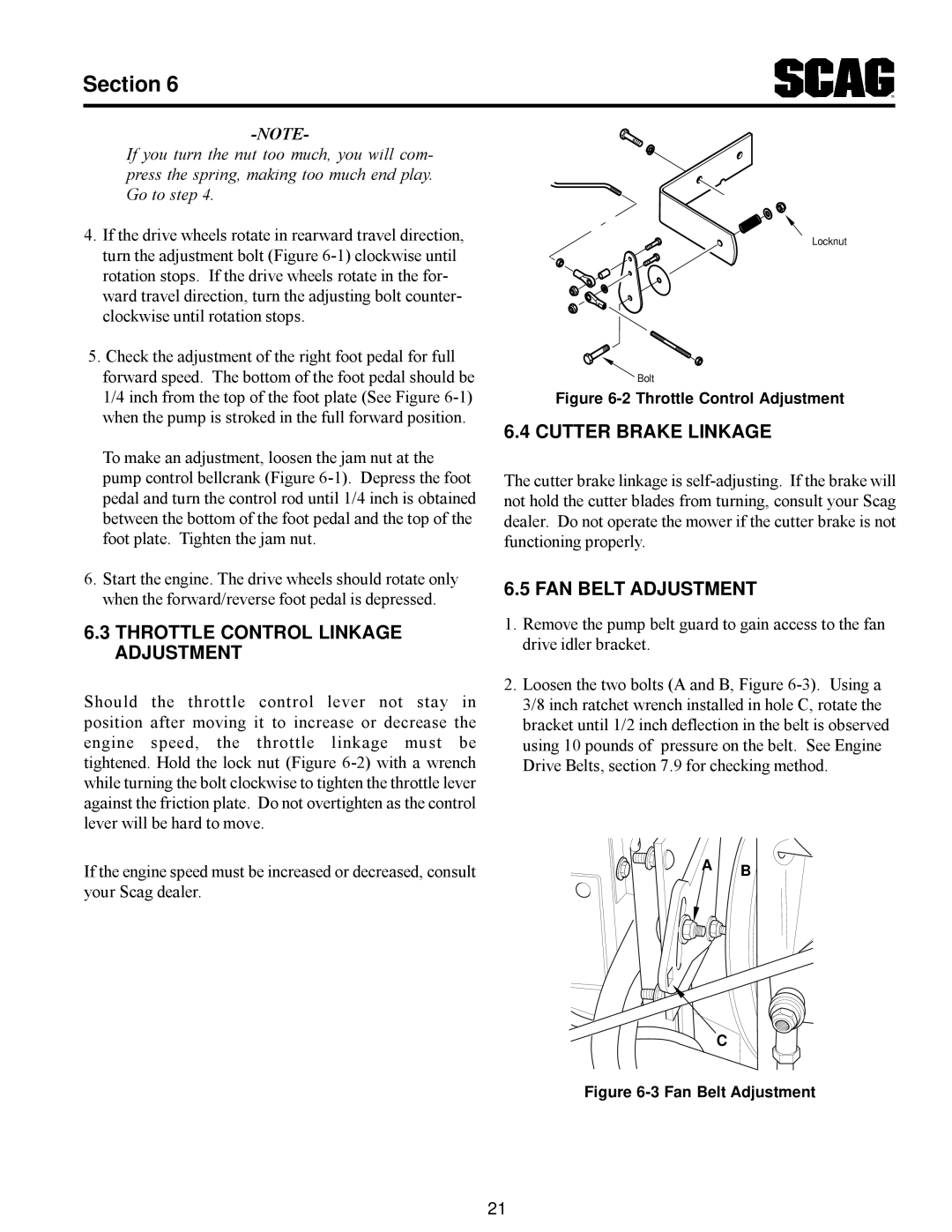

Should the throttle control lever not stay in position after moving it to increase or decrease the engine speed, the throttle linkage must be tightened. Hold the lock nut (Figure

Locknut

Bolt

Figure 6-2 Throttle Control Adjustment

6.4 CUTTER BRAKE LINKAGE

The cutter brake linkage is

6.5 FAN BELT ADJUSTMENT

1.Remove the pump belt guard to gain access to the fan drive idler bracket.

2.Loosen the two bolts (A and B, Figure

If the engine speed must be increased or decreased, consult | A | B |

| ||

your Scag dealer. |

|

|

C

Figure 6-3 Fan Belt Adjustment

21