Section 2 | R |

2.Remove the hairpin cotter pins and remove the two

(2) lock pins. See Figure

3.Lower the roll bar to the down position.

4.To raise the roll bar, lift the bar to the upright position.

5.Install the two (2) lock pins through the hole, secure with the two (2) hairpin cotter pins and tighten the tension knobs. See Figure

UPRIGHT AND

LOCkED POSITION

TENSION ![]()

![]()

kNOBS

Figure 2-1. Foldable Roll-Over Protection System

HAIR PIN

![]() WARNING

WARNING

Failure to properly inspect and maintain the seat belt can cause serious injury or loss of life.

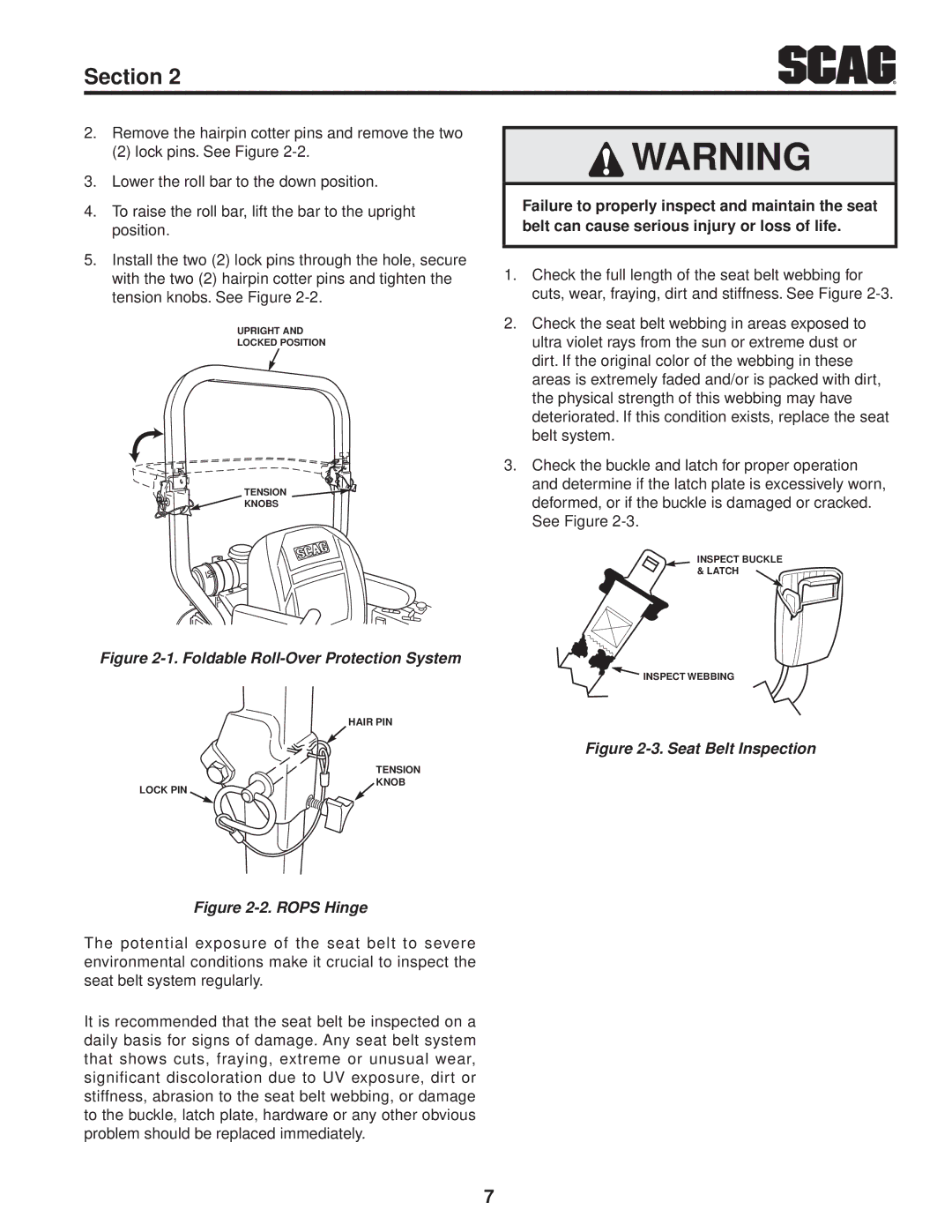

1.Check the full length of the seat belt webbing for cuts, wear, fraying, dirt and stiffness. See Figure

2.Check the seat belt webbing in areas exposed to ultra violet rays from the sun or extreme dust or dirt. If the original color of the webbing in these areas is extremely faded and/or is packed with dirt, the physical strength of this webbing may have deteriorated. If this condition exists, replace the seat belt system.

3.Check the buckle and latch for proper operation and determine if the latch plate is excessively worn, deformed, or if the buckle is damaged or cracked. See Figure

INSPECT BUCkLE

& LATCH

![]()

![]()

![]() INSPECT WEBBING

INSPECT WEBBING

Figure 2-3. Seat Belt Inspection

LOCk PIN

TENSION kNOB

Figure 2-2. ROPS Hinge

The potential exposure of the seat belt to severe environmental conditions make it crucial to inspect the seat belt system regularly.

It is recommended that the seat belt be inspected on a daily basis for signs of damage. Any seat belt system that shows cuts, fraying, extreme or unusual wear, significant discoloration due to UV exposure, dirt or stiffness, abrasion to the seat belt webbing, or damage to the buckle, latch plate, hardware or any other obvious problem should be replaced immediately.

7