NL35 Series FC

ST3500071FC ST3400071FC

Page

Contents

Installation

Defect and error management

Interface requirements

Seagate Technology support services

NL35 Series FC Product Manual, Rev. D

List of Figures

NL35 Series family disc drive

Viii NL35 Series FC Product Manual, Rev. D

Scope

NL35 Series family disc drive

NL35 Series FC Product Manual, Rev. D

Applicable standards and reference documentation

Standards

Electromagnetic compatibility

Electromagnetic susceptibility

Electromagnetic compliance

Environmental protection

Reference documents

Fibre Channel Interface Manual

NL35 Series FC Product Manual, Rev. D

General description

Standard features

Media description

Performance

Reliability

Formatted capacities

Factory-installed accessories

Factory-installed options

User-installed accessories

Programmable drive capacity

Performance characteristics

Internal drive characteristics

Seek performance characteristics

Access time

Generalized performance characteristics

GHz

Prefetch/multi-segmented cache control

Start/stop time

Cache operation

Caching write data

Prefetch operation

Page

NL35 Series FC Product Manual, Rev. D

Reliability specifications

Error rates

Reliability and service

Recoverable Errors

Unrecoverable errors

Seek errors

Mean Time Between Failure Mtbf

Preventive maintenance

Hot plugging the drive

4 S.M.A.R.T

Controlling S.M.A.R.T

Performance impact

Milliseconds

Temperature Log page 0Dh

Predictive failures

Thermal monitor

Parameter Code Description

State of the drive prior to testing

Drive Self Test DST

DST Failure Definition

Implementation

Invoking DST

Short and extended tests

Short test Function Code 001b

Extended test Function Code 010b

Product warranty

Abort

Shipping

Product repair and return information

Physical/electrical specifications

AC power requirements

DC power requirements

ST3500071FC/ST3400071FC DC power requirements

Power sequencing

General DC power requirement notes

Conducted noise immunity

Power dissipation

Temperature

Environmental limits

Relative humidity

Effective altitude sea level

Shock and vibration

Package size Packaged/product weight Drop height

Shock

Recommended mounting

Air cleanliness

Vibration

Corrosive environment

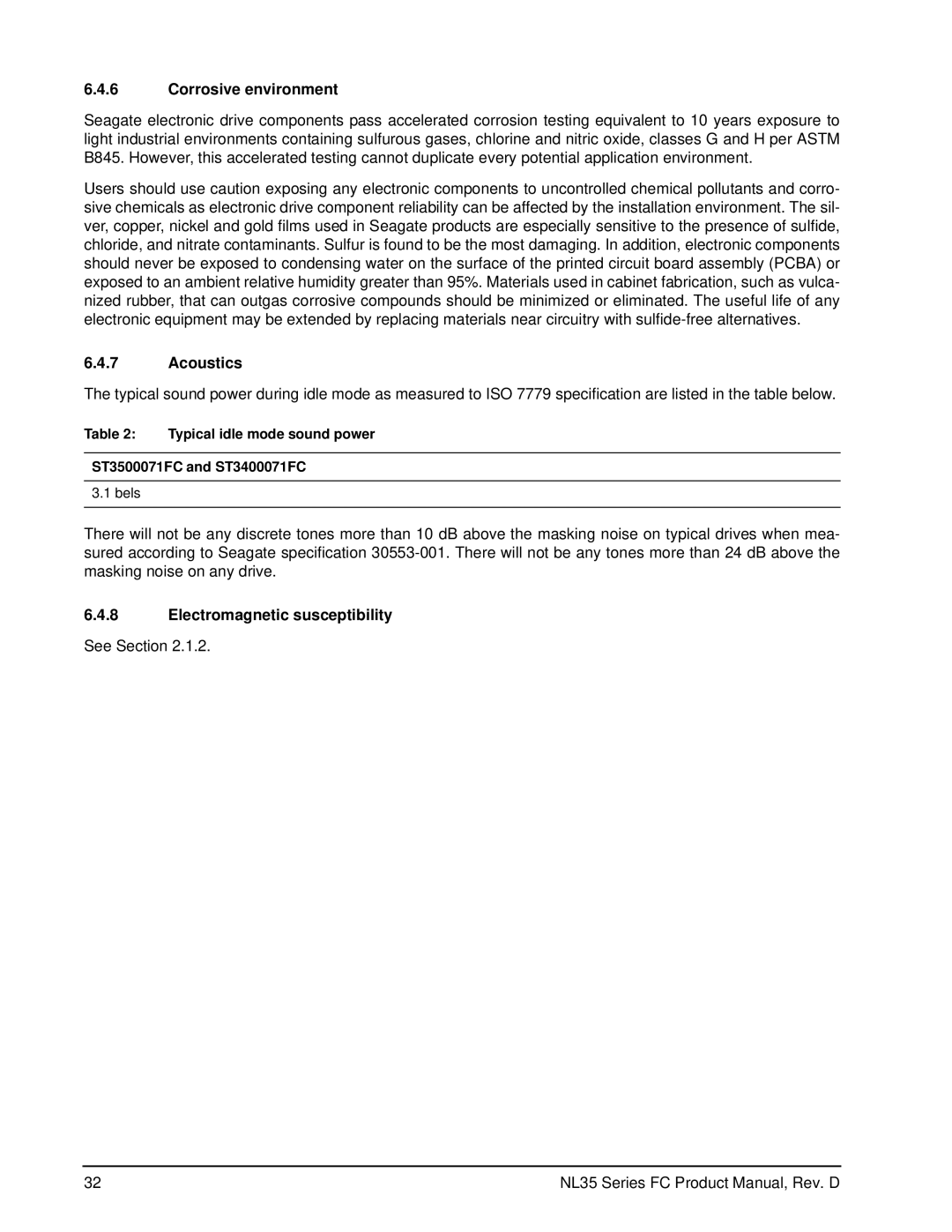

Typical idle mode sound power ST3500071FC and ST3400071FC

Acoustics

Mechanical specifications

Mounting configuration dimensions

NL35 Series FC Product Manual, Rev. D

Drive internal defects/errors

Defect and error management

Drive error recovery procedures

108.3

Background Media Scan

FC-AL system errors

Media Pre-Scan

NL35 Series FC Product Manual, Rev. D

Drive ID/option selection

Installation

Drive orientation

Cooling

Air flow

Drive mounting

Grounding

NL35 Series FC Product Manual, Rev. D

FC-AL features

Fibre Channel link service frames

Link services supported

Type of frame Link service

Fibre Channel task management functions

Fibre Channel Scsi FCP task management functions

Fibre Channel task management responses

FC Scsi FCP response codes

NPort login Plogi payload

Fibre Channel port login

Bytes

Fibre Channel port login accept

NPort Login Accept ACC payload

Fibre Channel Process Login

Process Login Plri payload

Fibre Channel Process Login Accept

Process Login Accept ACC payload

Fibre Channel fabric login

Fabric Login Flogi payload

Fibre Channel fabric accept login

Fabric Login Accept ACC payload

Dual port support

Fibre Channel Arbitrated Loop options

FC-AL options supported

Option Supported

Supported commands

Scsi commands supported

Command code Supported Command name

Supported commands

Supported commands

Supported commands

Supported commands

Mode Sense data

Inquiry data

NL35 Series inquiry data

Bytes Data hex

Page

DEF CHG

NL35 Series FC Product Manual, Rev. D

Miscellaneous operating features and conditions

Miscellaneous features

Supported Feature or condition

Miscellaneous status

FC-AL physical interface

Physical characteristics

Physical description

Part description Positions Part number Features

Connector requirements

Electrical description

Pin descriptions

Pin Signal name Signal type

FC-SCA pin descriptions

Fault LED Out

Power

FC-AL transmitters and receivers

Enable port bypass signals

Normal command activity LED status

Active LED Out

Active LED Out conditions

Motor start control signals

Parallel Enclosure Services Interface ESI

Motor start controls

11 SEL6 through SEL0 ID lines

Arbitrated loop physical address Alpa values

Setting

Hex Dec

Signal characteristics

LED driver signals

LED drive signal

Differential Pecl output characteristics

Differential Pecl input characteristics

Eye diagram data values

Link rate GHz

NL35 Series FC Product Manual, Rev. D

Seagate Technology support services

Internet

Presales Support

Technical Support

Data Recovery Services Authorized Service Centers

Warranty Service

Data Recovery Services Call Center Toll-free Direct dial

Index

Numerics

FAN

Flogi

Plogi

Page

See also cooling