SAFETY / INSTALLATION

4.Never run pump dry. To do so can damage internal parts, ovcrheat the pump (which can cause bums to peo- ple handling or servicing the pump), and will void the

warraoty I.

"_ DO NOT attcmI_t n) oil the i)uml) motor A special oil has been put into the motor housing at tilt" lhctot%': use ol any

other oil will vuid the warranty and could damage the pump.

6.This pump is recommended for use in permanent instal-

latinns only. This pump has not been invenstigatcd for use

in swimming pool areas.

7.Know the pump application, limitations, and potential hazards. Not lbr use with salt water or brine.

_Do |

|

| not use | in | explosive | atmospheres. | |

Pump water only with this | pump. | Failure | to follow | ||||

this warning | can | result | in | personal | injury | and/or | |

property | damage. |

|

|

|

|

| |

8.Release all pressure within the system before servicing any component.

9.Drain water from the system before servicing.

10.Secure the discharge line before starting the pump. An un-

secnred discharge line will whip, possible causing per- sonal injury and/or property damage.

11.Periodi _'callyinspect pump and system components. Pergoml

routine maintenance as required (See MAINTENANCE).

12.Provide a means of pressure relief for pumps whose dis- charge line can be

13.Personal Safety:

a.Wear safety glasses at all times when working with pumps.

b.Keep work area clean, tmcluttered and properly lighted - replace all unused tools and equipment.

c.Keep visitors at a safe distance from the work area.

d.Make workshop

switches, and by removing starter keys.

14.This equipment is only for use on 115 volt (single phase)

and is equipped with an approved

f AWARNING]To | reduce | the risk | of | electric | shock, |

| |||||||||

pull | plug |

| before | servicing. | This | pmnp | has | not | been | ||||||

investigated |

| for | use | in | swinlming |

| pool | areas. | This | ||||||

pump |

| is | supplied | with | a | grounding |

| conductor | and | ||||||

attachment | plug. | Be certain |

| that | it | ||||||||||

is connected | only to a | properly |

| grounded | ground- |

| |||||||||

| receptacle. |

|

|

|

|

|

|

|

|

|

| ||||

Where | a | wall | receptacle |

| is | encountered, |

| it | |||||||

must | be | replaced | with | a properly |

| grounded |

| ||||||||

receptacle |

| installed | in | accordance |

| with | the | National |

| ||||||

Electrical |

| Code and | local | codes | and ordinances. |

|

| ||||||||

15.Protect |

| electrical | cord | from | sharp | objects, hot surfaces, | |||||||||

oil, and | chemicals. | Avoid | kinking | the | cord. | Replace | or | re- | |||||||

pair damaged or worn cords immediately.

16.Do not handle a pump or pump motor with wet hands or when standing on a wet or damp surface, or in water.

&WARNING [Risk | of electric | shock. | If your basement | |||||||||||

has | water | or | moisture | on | the floor, | do | not | walk | on | wet | ||||

area | until | all | power | has | been | turned | off. | If | ||||||

box | is in | ba_sement, | call | the | electric | company |

| to shut- | ||||||

off service | to | the | house, | or | call | your | local | fire | depart- | |||||

nlent | for | instructions. | Remove | pump | and | repair | or | |||||||

replace. | Failure | to | follow |

| this | warning |

| can | result | in | ||||

fatal | electrical | shock. |

|

|

|

|

|

|

|

|

|

| ||

ADDITIONAL INSTALLATION

MATERIALS (Purchase Separately)

Sump Pump Hose Kit, SEARS Stock No. 27909, containing

24' (7.3M) of

adapter and stainless steel clamp. We recommend a Check Valve, SEARS Stock No. 2789 or 2792.

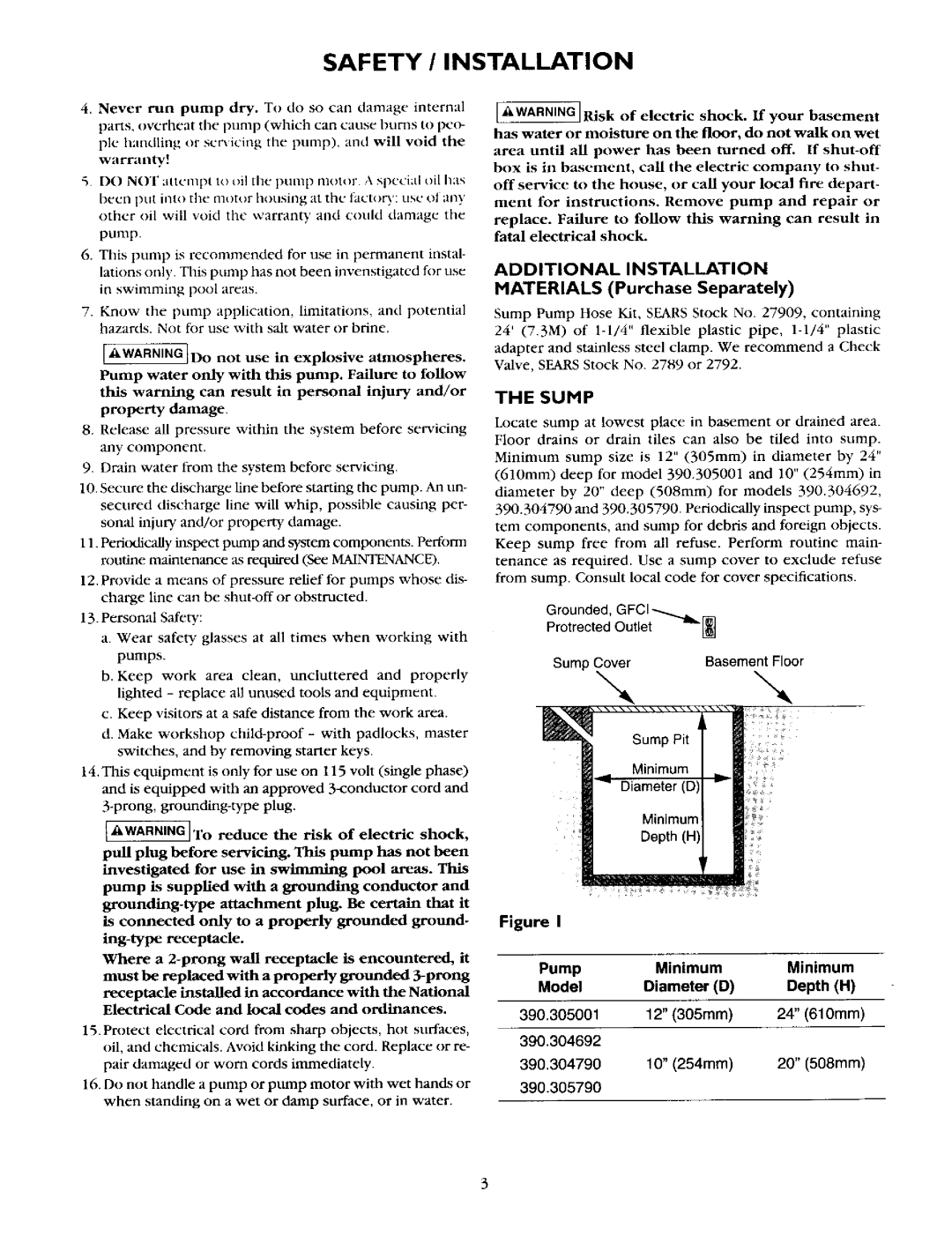

THE SUMP

Locate sump at lowest place in basement or drained area. Floor drains or drain tiles can also be tiled into sump.

Minimum sump size is 12" (305mm) in diameter by 24"

(610mm) deep for model 390.305001 and 10" (254mm) in

diameter by 20" deep (508mm) for models 390.304692,

390.304790 and 390.305790. Periodically inspect pump, sys-

tem components, and sump for debris and foreign objects.

Keep sump free from all refuse. Perform routine main-

tenance as required. Use a sump cover to exclude refuse from sump. Consult local code for cover specifications.

Grounded, GFCl _ .

Protrected Outlet _"[_

Sump Cover |

|

| Basement | Floor | |

|

| ||||

,\\\\\\\xxxx\_.\ |

|

|

|

|

|

| Sump | Pit |

|

|

|

| Minimum |

|

|

| |

Diameter | (D) | _ | ', | ' | |

| Minimum |

|

|

| |

| Depth | (H) |

|

|

|

|

| _F |

|

| |

Figure I |

|

|

|

|

|

Pump | Minimum |

| Minimum | ||

Model | Diameter | (D) |

| Depth (H) | |

300.305001 | 12" (305mm) |

| 24" (610ram) | ||

390.304692 |

|

|

|

|

|

390,304790 | 10" (254mm) |

| 20" (508mm) | ||

390.305790 |

|

|

|

|

|