INSTALLATION / OPERATION / ELECTRICAL

PUMP INSTALLATION

Set the pump on the bottom of the sump, making sure that

it sits solidly and is level. Be sure there is enough space

around the punlp to allow the switch frec mo_ cnlcnt ;is the

stimp water level changes. Du Rot iitstall the ptimp on clay, earth, or sand surlTace.

i

I _" CAUTION IRisk

.I of flooding. If a flexible discharge

hose is used, pump may move around in sump when

niotor starts. If it moves far enough so that tile switch hits the side of the sump, the switch may stick and prevent pump from starting. Make sure that pump is secured so that it cannot walk arotmd in sump.

Hose Kit No. 27909 can be used as the discharge pipe. Run the discharge pipe to the nearest sewer outlet or other point of disposal. Use the most direct route and the fewest turns and elbows possible.

Use Teflon tape to seal threads in plastic pipe. Hand tighten only.

NOTE: To avoid backflow into sump when pump shuts off, install a Check Valve, SEARS Stock No. 2789, in threaded dis- charge port of pump. A SEARS No. 2789 Check Valve is con- structed with an

just above the pump discharge port and below the Check Valve to prevent pump from airlocking.

Make sure the

AUTOMATIC FLOAT SWITCH

INSTALLATION AND OPERATION

Your SEARS Model 390.305001 Submersible Drainer comes

with the automatic float switch mounted on the motor hous-

ing ready for operation. Tether length is factory set at 3"

(76mm). Do not change tether length. See Page 6 for verti- cal float switch instructions.

I AWARNING_ Risk of electric shock. Always disconnect

the pump and switch from the electrical power source

before doing any maintenance!

Follow instructions below to install pump with factory

mounted switch:

1.Be sure automatic float can swing freely through its entire

arc without interference from pump, piping, sump wall or any other object.

2.Plug the automatic switch cord into a properly grounded

outlet (see "Electrical Connections", Page 4). Plug the pump power cord into the back of the switch plug.

3.Test the installation by adding water to the sump pit until

pump operates normally as follows:

A.When sump is dry, the watertight automatic float

switch is hanging in a downward position and the pump is off.

| B. As water | comes | into | the |

| sump, |

| tile | auton/atic | float | |||||

| switch | rises | to | an | upward | position | and | the | pump starts. | ||||||

| (7. Water | will | contint_e to | be | pumped |

| until | the | float | switch | |||||

| is | hanging |

| ill | the | dox_nward | position | agaiit, | when | ||||||

| pump | will |

| stop. |

|

|

|

|

|

|

|

|

| ||

DO NOT ALLOW PUMP TO RUN DRY! |

|

|

| ||||||||||||

Be | sure | to | leave | at least | 5" | (127mm) | of water | above | |||||||

pump | base | plate | when | pump | stops. | Running | pump | ||||||||

dry | could | ruin |

| the | pump | and | will | void | the | warranty. | |||||

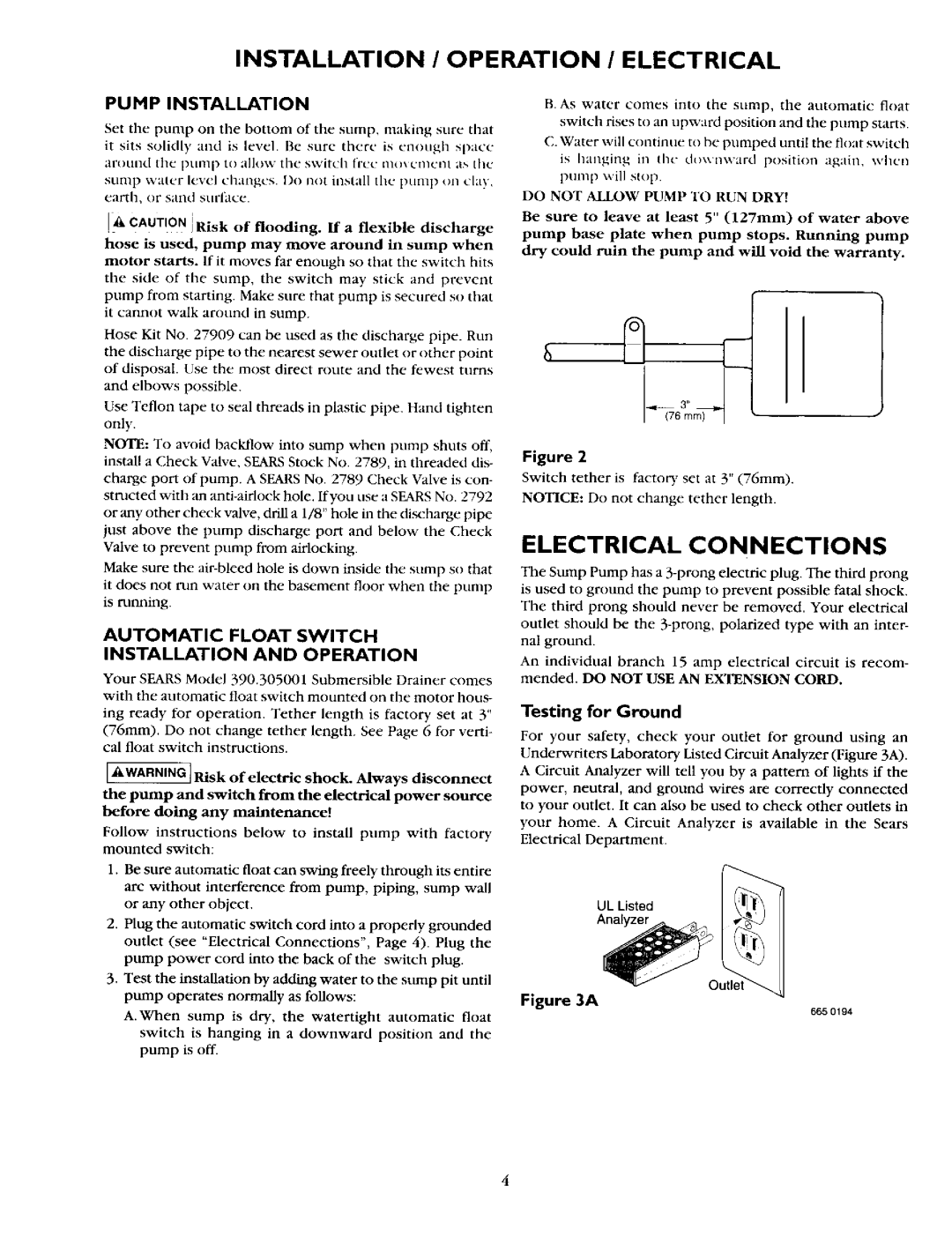

Figure 2

Switch tether is factor), set at 3" (76mm).

NOTICE: Do not change tether length.

ELECTRICAL CONNECTIONS

The Sump Pump has a

The third prong should never be removed. Your electrical

outlet should be the

An individual branch 15 amp electrical circuit is recom-

mended. DO NOT USE AN EXTENSION CORD.

Testing for Ground

For your safety, check your outlet for ground using an

Underwriters Laboratory Listed Circuit Analyzer (Figure 3A). A Circuit Analyzer will tell you by a pattern of lights if the

power, neutral, and ground wires are correctly connected

to your outlet. It can also be used to check other outlets in

your home. A Circuit Analyzer is available in the Sears Electrical Department.

UL Listed | [_ |

Figure 3A

665 0194

4